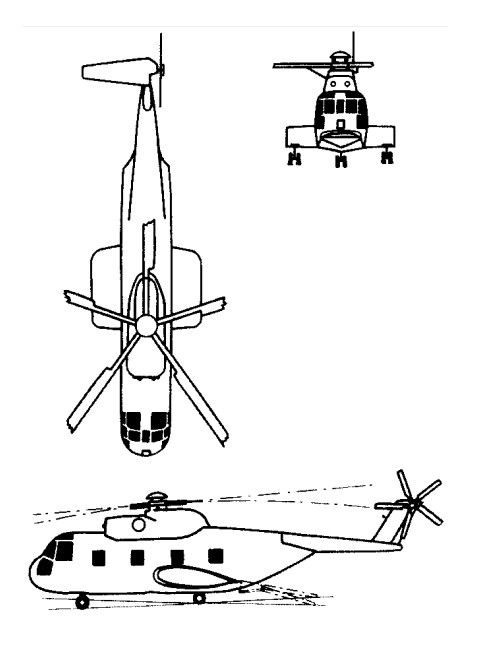

On the basis of the S-61R project for the Marines, the American company proposed the S-65A with a completely redesigned, large-capacity fuselage, capable of transporting 37 equipped troops or 24 stretchers with 4 medical attendants.

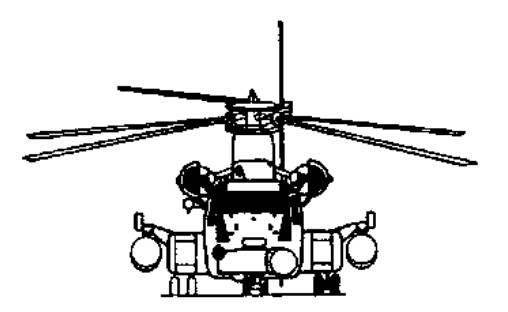

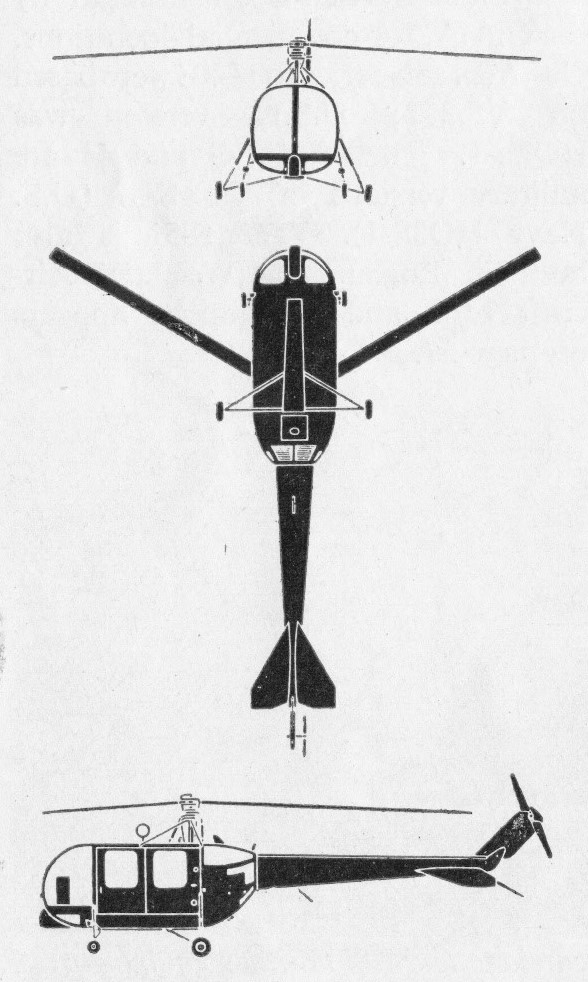

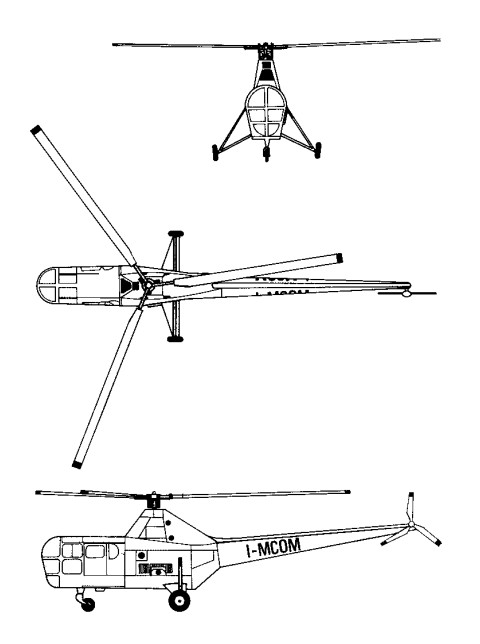

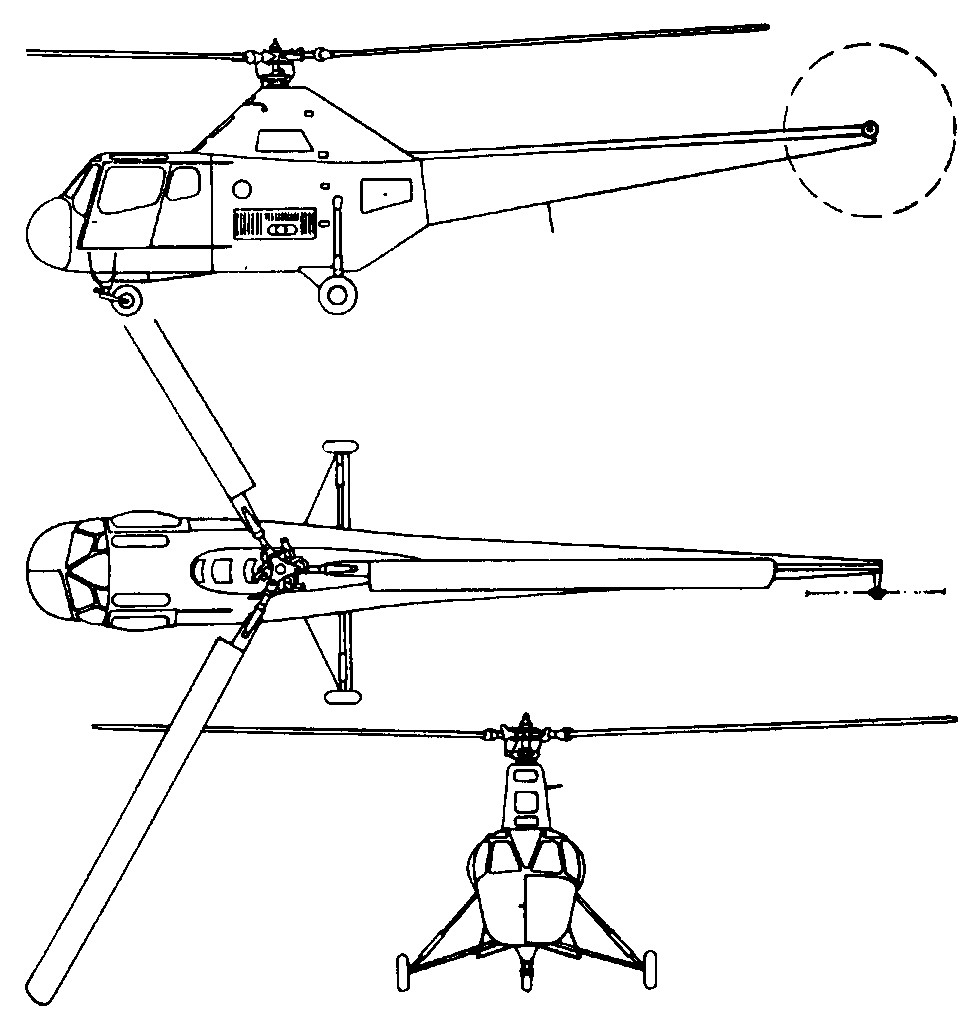

The S-65A fuselage is a scaled-up version of that used on the S-61R. The fuselage is a conventional semi-monocoque structure of aluminium, steel and titanium, a folding tail pylon, and with a horizontal stabiliser on the starboard side of the tail rotor pylon. The rotor system and transmission are generally similar the S-64A Skycrane, but the main rotor head is of titanium and steel, and has folding blades. The flat-bottomed body is watertight and has similar sponsons amidships in which are housed fuel tanks and the main undercarriage members when retracted. The fully castoring nosewheel is also fully retractable. The retractable tricycle type landing gear, has twin wheels on each unit. Main units retract into rear of sponsons on each side of fuselage. Mainwheels and nosewheels have tyres size 25.65 x 8.50-10, pressure 6.55 bars. Basic empty weight is reduced by the use of titanium in the rotor head. The S-65A carries a crew of 3 and can airlift 38 troops and their equipment, 24 casualty litters and 4 medical attendants, or some 3630kg of cargo within the fuselage. The interior of the CH-53 is fitted with rollers for easy movement of cargo. A let-down rear ramp provides access for such military loads as 2 jeeps, a Hawk missiles, or a 105mm howitzer and its carriage. A slung load of some 5900kg can be lifted on an under-fuselage hook.

Power is normally two 2,850 shp / 2,125kW General Electric T64-GE-6 turboshaft engines, mounted in pod on each side of main rotor pylon. The CH-53A can also utilise, without airframe modification, the T64-GE-1 engine of 2,297kW or the later T64-GE-16 (mod) engine of 2,561.5kW. Two self-sealing bladder fuel tanks, each with capacity of 1,192 litres, housed in forward part of sponsons. Total fuel capacity 2,384 litres.

With a crew of three, the main cabin accommodates 37 combat-equipped troops on inward-facing seats. Provision for carrying 24 stretchers and four attendants. Roller-skid track combination in floor for handling heavy freight. Door on starboard side of cabin at front. Rear-loading ramp.

The first flying on 14 October 1964, the YCH-53A Sea Stallion demonstrated ruggedness of design by flying with three of six main rotor blades removed, and also performed a barrel-roll. Two YCH-53A were built, 151613 and 151614. One commercial demonstrator was later sold to NASA.

The US Navy, which is responsible for acquisitions for the Marines, in August 1962, announced that the S-65A had been selected as a new ship-borne heavy assault transport for the U.S. Marine Corps, with the military title CH-53A Sea Stallion.

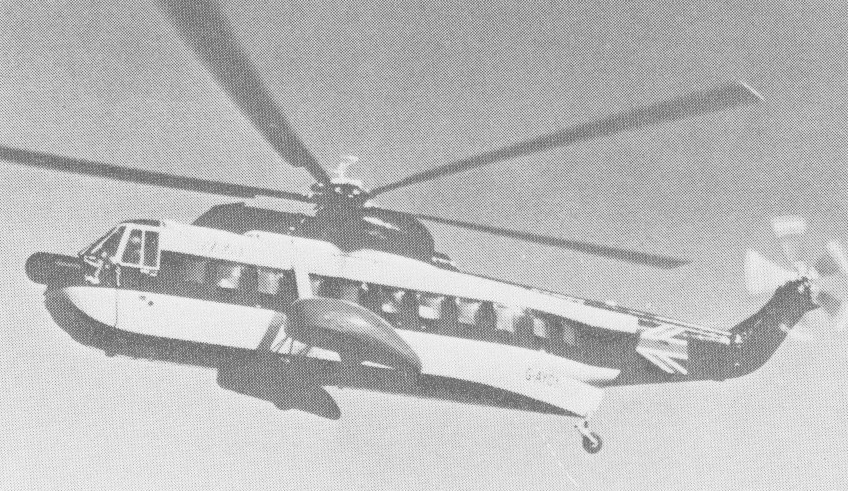

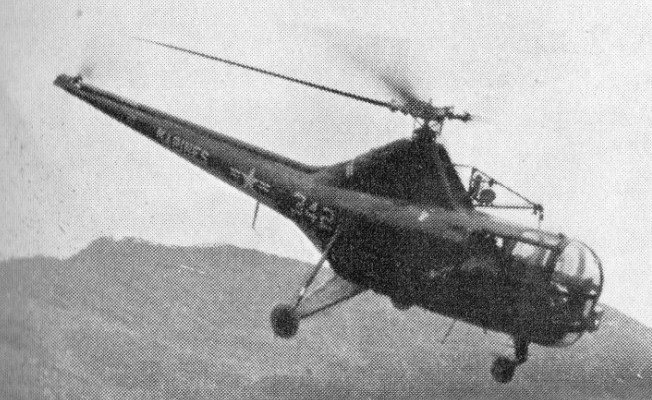

The first Sea Stallion flew on 14 October 1965 powered by two 2125kW General Electric T64-GE6 engines, and delivery of the first 106 helicopters began in September 1966. The aircraft were assigned to Marine Squadron HMH-463 in Vietnam in January 1967. At that period, it was the largest helicopter in the Western world.

On 17 February 1968, a CH-53A with modified T64 engines took off with a gross weight of 23540kg and a 9925kg payload, establishing an unofficial record. On 23 October of the following year a Sea Stallion demonstrated surprising manoeuvrability when it performed a series of loops and rolls with Lt.-Col. Robert Guay of the Marines and Sikorsky test pilot Byron Graham at the controls, carrying a gross weight of 12250kg. During these manoeuvres, the helicopter supported from -0.2 to 2.8g.

Delivery of the first of one hundred and six production CH-53A’s began in September 1966. Since January 1967 the Sea Stallion has been serving with Marine Squadron HMH-463 in Vietnam, and by that summer some thirty Sea Stallions had been delivered. Standard powerplant is the T64-GE-6 shaft turbine, though the 3080shp T64-GE-1, 3435shp T64-GE-16 or GE T64-GE-3/-6/-12 may be fitted. One CH-53A with standard engines has been flown at a gross weight of 20865kg, of which 9072kg was payload. One hundred ad thirty-nine were built; 151686 to 151701, 152392 to 152415, 153274 to 153313, 153705 to 153739, 154863 to 154888, and 63-13693 to 13694, of which 15 transferred to USN as RH-53A and 9 to USAF, 66-30047, -30049, -30050, 67-30043 to 30046, -30048, and -30051. 152399 went to the FAA as NCH-53A and wore a civil license.

In September 1966, the USAF also ordered this big helicopter for its rescue service to assist space programmes and recover pilots from war zones. The eight HH-53B, 66-14428 to 14435, ordered for the USAF were known as “Super Jolly Green Giants” and fitted with in-flight refuelling probes, jettisonable auxiliary fuel tanks, rescue hoists and all-weather avionics. Flown for the first time on 15 March 1967. This version has 3080shp T64-GE-3 engines. It also has defensive machine gun positions fore and aft.

A batch of eleven ex-USMC, 66-14468 to 14478, went to the USAF in 1988 as TH-53A.

The HH-53B is employed by the Aerospace Rescue and Recovery Service of the U.S. Air Force, and delivery of an initial batch began in June 1967. Two of these aircraft were stationed at Cape Kennedy in connection with the Apollo manned spacecraft programme.

Parallel with the military variants, Sikorsky had under development a commercial model of the S-65A. This was currently envisaged with 3435shp T64 engines and an enlarged pressurised fuselage to seat 67 passengers.

Fifty-eight of the subsequent HH-53C variant with uprated turbines (3435shp each) were built from 1967. Used for space capsule recovery and combat SAR, they were similar to HH-53B, but with 3925hp T64-GE-7 engines and jettisonable fuel tanks.

The CH-53C Super Jolly was as the HH-53C, but in transport roles. Twenty were built, 68-10922 to 10933, and 70-1625 to 1632.

After having used the early production aircraft, the US Marine Corps also asked for more powerful engines to be installed, and the result was the CH-53D, introduced in March 1969, with 3925shp / 2927kW T64-GE-413 engines. In this version, the tail and rotor could be folded back automatically, and a high density cabin layout was available to accommodate 64 troops, equivalent to the S-65C export version. All but the first 34 had fittings to operate as minesweepers. A total of 265 CH-53As and Ds were built for the Marines; the last left the factory on 31 January 1972.

Of the early versions, all are transports (139 CH 53As and 126 of the more powerful CH 53D, all for the US Marines) except for 15 CH-53A, including 152392-152398, transferred to the US Navy as RH 53A Sea Stallion minesweeping machines with T64-GE-413 engines in 1971.

Last CH-53D (the 26th built) was delivered on 31 January 1972. All but the first 34 CH-53s were provided with hardpoints for supporting towing equipment and transferring tow loads to the airframe, so that the US Marine Corps could utilise the aircraft as airborne minesweepers, giving an assault commander the capability of clearing enemy mines from harbours and off beaches without having to wait for surface minesweepers.

Tow kits installed in the 15 CH-53Ds operated by the US Navy Squadron HM-12 included automatic flight control system interconnections to provide automatic cable yaw angle retention and aircraft attitude and heading hold. Rearview mirrors are fitted for pilot and co-pilot; tow cable tension and yaw angle indicator; automatic emergency cable release; towboom and hook system with 6,803kg load capacity when cable was locked to internal towboom. A dam to prevent cabin flooding in emergency water landing with lower ramp open; dual hydraulically powered cable winches; racks and cradles for stowage of minesweeping equipment; auxiliary fuel tanks in cabin to increase endurance.

HH-53B and HH-53C SAR variants were built for the US Air Force, the former equipped to a standard similar to that of the HH-3E and powered by 2297kW T64-GE-3 engines. It was first flown on 15 March 1967. Sponson bracing struts allowed the HH-53B to carry 2460-I drop-tanks. More powerful 3,925kW T64-GE-7 engines powered the improved HH-53C, the same powerplant being installed in the CH-53G produced for the German army. Two S-65Oe rescue helicopters were delivered to the Austrian air force in 1970.

S-65C-3 were sold to the Israel Defense Force/Air Force.

A specialised minesweeping version, the RH-53D, was first flown on 27 October 1972 with drop-tanks and in-flight refuelling probes. To complete its experiments with the RH-3A, the US Navy borrowed nine CH-53Ds from the Marines, fitted with devices for the detection, sweeping and neutralization of all types of mines. This variant was designated RH-53D, and 30 were produced for the US Navy and six for the Iranian Navy in 1978. The RH-53 has 1900 liter supplementary fuel tanks, a 270kg hoist and 11340kg cargo hook. Minesweeping equipment is towed behind the helicopter on a trapeze. Towing equipment was installed from the 34th production aircraft onwards. Once brought to the surface, mines are detonated using two door-mounted machine-guns. Though a dedicated minesweeper, the RH-53D also has a transport role. At the beginning of 1973, these helicopters were used by US Navy Task Force 78 for Operation Endsweep, to free the North Vietnamese ports of mines. Some ships used for tests were designated as NRH-53D.

Eight RH-53Ds were used to fly into Iran during Operation Eagle Claw to rescue the hostages held by Iran in 1980; seven were destroyed. RH-53Ds were deployed to the Persian Gulf for minesweeping operations in 1987, and in 1991 for Desert Storm.

Two VH-53D Sea Stallion were USMC staff transport.

The Sea Stallion also aroused some interest in other countries where there was a requirement for a helicopter for troop transport. Thus the S-65A was also ordered by Germany. Two pattern aircraft were built in the US and 110 were built under license by VFW-Fokker as the CH-53G with T64-GE-7 engines. Another eight aircraft, modified for use in hot/high conditions, were exported to Israel.

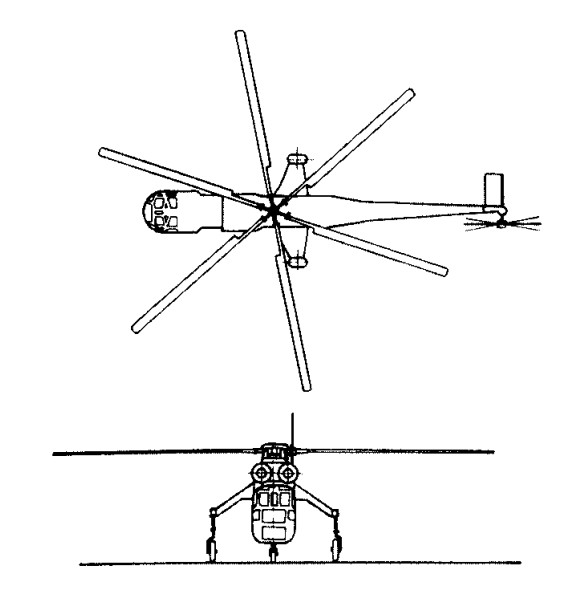

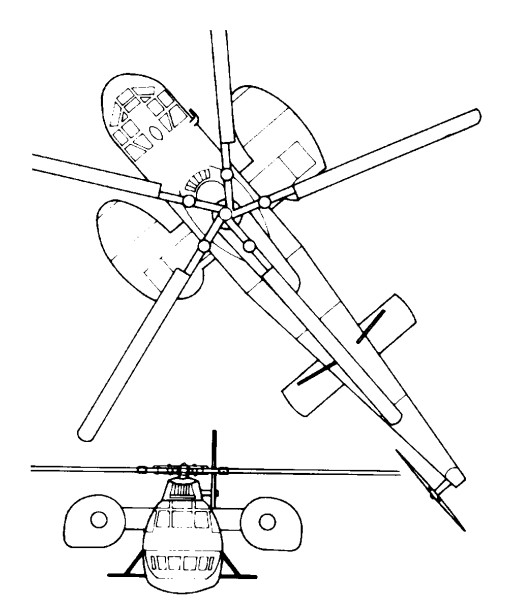

Work began in 1971 on an enlarged version with a lengthened fuselage, a new rotor system and three 3266kW T64-GE-416 engines. The US Navy contract covering two prototypes and subsequent flight test was awarded in 1973, and the S-80 / YCH-53E prototype (71-59121) flew for the first time on 1 March 1974. During tests it was hovered at 50′ at a gross weight of 71,700 lb on 10 August 1974, carrying an external load of 17.8 tons, the heaviest gross weight ever flown and heaviest payload ever lifted by a helicopter in the western world. With the three engines each of 4,380 shp (3266 kW) it was the most powerful helicopter ever built outside the Soviet Union. First flight of first production prototype was on 8 December 1975, and the second production prototype in March 1976. Fitted with in-flight refueling, two YCH-53E Super Stallion prototypes were built.

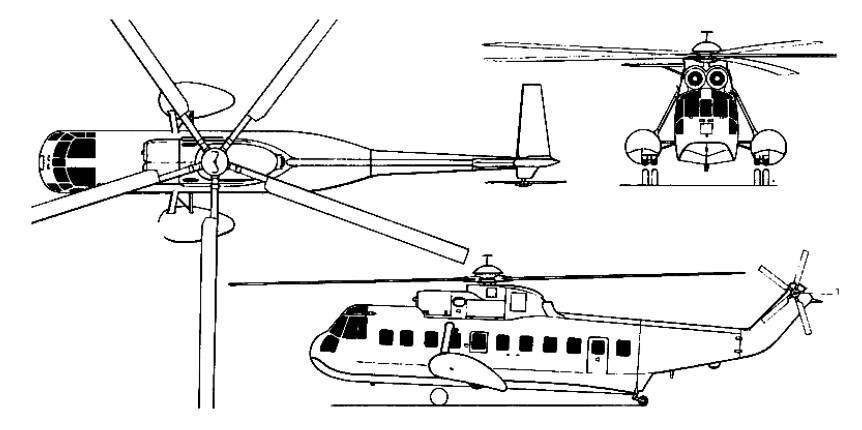

This is a much modified version with three 4380shp General Electric T64-GE-416 engines and strengthened transmission to withstand the increase in power. The fuselage is about 2m longer than that of the CH-53D and the tail pylon is canted to port. The main rotor has also been improved and has seven composite blades (its predecessor had six light alloy ones) of increased diameter. Thirty-three CH-53Es were initially ordered by the Marines and 16 by the US Navy.

The first production CH 53E flew on 13 December 1980, and the first delivery of a CH-53E took place on 16 June 1981 at Stratford, Con. This CH-53E (the sixth of the initial production lot, the preceding five serving as acceptance test procedures, avionics testing, maintenance and pilot training programs) entered service with HMH-464 Marine Aircraft Group 26. It was the first of 20 contracted.

By mid 1983 more than 40 had been delivered out of 72 ordered. Specifically designed for USN/USMC, they carried 55 troops and two 650-gallon fuel tanks on sponsons, A total of 103 CH-53 were built.

JCH-53E and NMH-53E were designations for test aircraft.

Full-scale development of Helicopter Night Vision System (HNVS) for CH-53E began June 1986, in co-operation with Northrop Electro-Mechanical Division; HNVS includes Lockheed Martin Pilot Night Vision System (PNVS) and Honeywell Integrated Helmet and Display Sighting System (IHADSS) from Bell AH-1S surrogate trainer; HNVS will allow low-level operations in night and adverse weather; HNVS ground testing began 1988; operational evaluation began August 1989. Smaller-scale capability authorised 1993, with contract to EER Systems for installation of Hughes AN/AAQ-16B FLIR, Teledyne Ryan Electronics AN/APN-217 Doppler and Rockwell Collins GPS 3A; total 24 upgrades initially authorised; subsequent contracts for 99 HNVS with work scheduled for completion in May 1999. USMC has also evaluated engine-suppression system as means of reducing IR signature, and new multiple cargo hook concept.

The CH-53E can accommodate 55 fully equipped combat troops, wheeled vehicles, and palletised cargo, and has a 16-ton heavy-lift capability. In-flight refuelling plus a folding rotor and tail boom for shipboard stowage are also provided.

The first CH-53E Super Stallion delivery to the US Marine Corps took place on 16 June 1981. Since 1982 Sikorsky has been developing the MH-53E mine countermeasures variant. It incorporates major equipment changes and has much enlarged sponsons to carry an additional 3785 litres of fuel. Six were delivered in 1986. June 1987 marked six years in service for the CH-53E Super Stallion.

In addition Sikorsky is de¬veloping the derived MH 53E as a de¬finitive MCM (mine countermeasures) helicopter, with very comprehensive minesweeping gear using all existing or planned MCM devices. Enormously enlarged side sponsons accommodate an extra 3785 litres (833 Imp gal) of fuel, for extended sweeping missions with the engines at sustained high power, The MH 53E will also be used in the vertrep (vertical replenishment of ships) role, and has been made com¬patible with the cargo hold of the Lock¬heed C 5 Galaxy in order that it can be deployed rapidly anywhere in the world. Bureau number 162497 was the first true production MH53E. The first delivery (of 35 built) of an MH-53E Sea Dragon airborne mine counter¬measures (AMCM) helicopter to a US Navy fleet squadron took place in April 1987. Based on the triple-turbine CH-53E airframe, the MH-53E has extra-large sponsons made of composite material, each holding 1,600gal of fuel allowing a 4hr minesweeping mission. To accomplish its task the Sea Dragon tows mechanical, acoustic, and magnetic hydrofoil sweeping gear through the water. A dual digital automatic flight control system allows automatic approach to, and departure from, a coupled hover, with tow cable tension and skew-angle hold functions. In-flight refueling capability aids rapid long-range deployment, while rotor-blade and tail-boom folding ensures compatibility with all US Navy AMCM ships.

Delivery effected 1994 of MH-53E retrofitted with upgraded avionics package by EER Systems, comprising two 15.2 cm (6 in) horizontal situation display colour screens, Fairchild mission data loader and Rockwell Collins GPS 3A; upgrade of entire MH-53E fleet planned but may be reduced to around 30 as result of defence budget trimming. One MH-53E to West Palm Beach, Florida, for installation of T64-GE-419 engines, late 1993. Trials during 1994 verified performance gains, including recovery and flyaway capability in event of engine failure during hover; retrofit of entire MH-53E fleet underway.

First flight of preproduction MH-53E, 1 September 1983; first delivery to US Navy 26 June 1986; in operational service with HM-14 at Norfolk, Virginia, 1 April 1987; first carrier deployment by HM-15 on board USS Tripoli, 9 December 1989.

Delivery effected 1994 of MH-53E retrofitted with upgraded avionics package by EER Systems, comprising two 15.2 cm (6 in) horizontal situation display colour screens, Fairchild mission data loader and Rockwell Collins GPS 3A; upgrade of entire MH-53E fleet planned but may be reduced to around 30 as result of defence budget trimming. One MH-53E to West Palm Beach, Florida, for installation of T64-GE-419 engines, late 1993. Trials during 1994 verified performance gains, including recovery and flyaway capability in event of engine failure during hover; retrofit of entire MH-53E fleet underway.

Export versions of the CH-53E and MH-53E were available as the S-80E and S-80M respectively.

Some CH-53C and HH-53B helicopters remained unmodified until the late 1980s, when they became MH-53Js.

MH-53H and MH-53J Pave Low IIs were involved in the US invasion of Panama. Air Force special operations HH-53Hs and MH-53Js are rebuilds of HH-53B/Cs.

The 1975 HH-53H Super Jolly was a USAF 24-hour, all-weather SAR in the PAVE LOW program. One prototype was completed and eight conversions of HH-53C in 1979.

The 1981 MH-53J PAVE LOW IIIE were for heavy-lift, all-weather, long-range, undetected penetration. They were the largest and most powerful helicopter in USAF at the time, featuring PAVE low-level terrain-avoidance radar and forward-looking infrared sensors (FLIR), along with a projected map display, enabled pilot to follow land contours and avoid obstacles.

Six Sikorsky VH-53F Super Stallion were ordered for the USAF but with US Navy bureau numbers (159123 / 159128) for VIP transport by the 89th Military Airlift Wing. These were cancelled before deliveries could take place.

Production:

151613-151614 (2) YCH53A

151686-154884 (128) CH53A

156654-157931 (126) CH53D

158682-158761 (30) RH53D

161179-165651 (177) CH53E

161395-164864 (48) MH53E

168778-168782 (5) YCH53K (1 GTV, 5 EDM)

Bureau number 161395 was later converted from a CH53E to MH53E

Variants:

YCH-53A

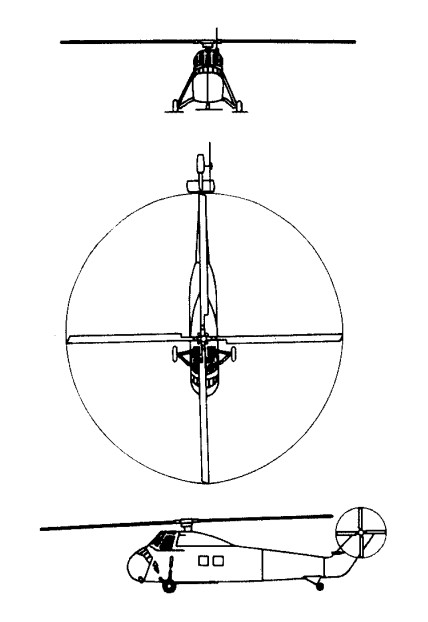

Winner of the HH(X) competition, two prototype CH-53As were completed for US Navy evaluation, by March 1966; first flight made by second aircraft (BuNo. 151614) on 14 October 1964, powered by two T64-GE-6 turboshafts

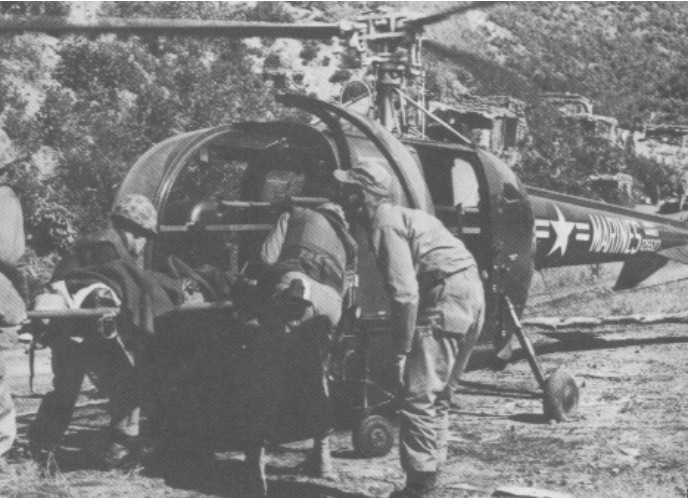

CH-53A

Initial version powered by two General Electric T64 turboshaft engines and has a watertight hull for US Marine Corps, deliveries commencing in September 1965. A full-size rear opening, with built-in ramp, permits easy loading and unloading, with the aid of a special hydraulically operated internal cargo loading system and floor rollers. Accelerated deployment to South East Asia made after improvements to engine intake filters, defensive armament, crew armour and external lifting capability; selected T64-GE-1 engines retrofitted for extended running at maximum power output when necessary; fitted with hardpoints for towing mine-sweeping gear from 34th aircraft onwards; used by USAF for crew training and later for covert operations in Vietnam and Laos (seven aircraft borrowed from and returned to Navy); 139 built

RH-53A

15 dedicated mine-counter-measures versions delivered to the Navy via the Marine Corps; re-engined with T64-GE-413 turboshafts; rectangular frame mounted on rear ramp to tow mine clearing sled and rear view mirrors fitted on either side of the nose; used to clear North Vietnamese mines during Operation Endsweep in 1973; RH-53As replaced by RH-53Ds in Navy service and aircraft returned to Marines

TH-53A

Former USMC CH-53As used by USAF from 1989 onwards to train MH-53 crews at Kirtland AFB, NM; at least three aircraft in use, stripped of most equipment and camouflaged

HH-53B

Eight aircraft similar to CH-53A but delivered to USAF Aerospace Rescue and Recovery Service to supplement HH-3s in South East Asia. The first of these flew 15 March 1967, powered by 2,297kW T64-GE-3 turboshaft engines. Refuelling probe relocated to starboard side of nose, pylons fitted to allow carriage of external fuel tanks; armed with three pintle-mounted GAU-2A/B 7.62mm Miniguns and powered by T64-GE-3s, later replaced by T64-GE-7s; quickly supplemented by HH-53Cs and re-assigned to CONUS, the last four HH-53Bs were modified to MH-53J standard in the late 1980s

CH-53C

22 aircraft built for heavy-lift duties with the USAF; fitted with sponsons and external tanks as developed for HH-53C, it was similar in most respects to this version but lacked a refuelling probe; replaced CH-53As on loan from USMC for covert operations in Laos; later operated by TAC and USAFE; seven surviving CH-53Cs brought up to MH-53J standard in late 1980s

HH-53C

Refined version of HH-53B, with 2,927kW T64-GE-7 engines. 44 were built for USAF ARRS for combat rescue; dubbed ‘Super Jolly Green Giant’; dispensed with bracing struts fore the external pylons, and included additional crew armour, and better radio fit to facilitate operations with HC-130 tankers. Auxiliary jettisonable fuel tanks each of 1,703 litres capacity on new cantilever mounts. Flight refuelling probe, and rescue hoist with 76m of cable. External cargo hook of 9,070kg capacity. RHAW and IR jamming systems introduced as a result of experience in North Vietnam during 1972; HH-53Cs used in support of Apollo space missions for emergency capsule rescue; HH-53Cs remained in USAF service until late 1980s when all were converted to MH-53J standard

First HH-53C was delivered to the USAF 30 August 1968. A total of 72 HH-53B/Cs was built.

S-65C

Commercial intercity helicopter proposal based on military CH-53.

S-65C-2 / S-65O

Export version of CH-53C, two of which were ordered in 1969 and delivered to the Austrian air force in 1970; later retired from use due to operating costs and passed on to Israel in 1981. Used for rescue duties in the Alps, they have the same rescue hoist as the HH-53B/C, fittings for auxiliary fuel tanks and accommodation for 38 passengers.

S-65-C3

Only other export version of H-53, delivered to Israel from 1969; corresponding to HH-53C, 33 aircraft supplemented by two additional S-65s from Austria in 1981; surviving aircraft upgraded by IAI subsidiary MATA Helicopters

CH-53D

Improved CH-53A for US Marine Corps, the first of which was delivered on 3 March 1969. Two T64-GE-413 engines, each with a maximum rating of 2,927kW. A total of 55 troops can be carried in a high-density arrangement. An integral cargo handling system makes it possible for one man to load or unload 1 ton of palletised cargo a minute. Main rotor and tail pylon fold automatically for carrier stowage, first flown on 27 January 1969; 124 built.

RH-53D

First flown 27 October 1972; 30 aircraft (named Sea Stallion) specifically developed for anti-mine warfare in the light of positive experience with RH-53A; fitted with an initial powerplant of two T64-GE-415s, RH-53D also differs from RH-53A by inclusion of refuelling probe, automatic flight control system, more powerful cargo hook, and rescue winch; armed with two’swivel-mounted 12.7mm machine-guns; six delivered to Imperial Iranian navy before the fall of the Shah

VH-53D

Two CH-53Ds delivered to USMC for VIP transport

YCH-53E

Three-engined development of the CH-53D.\

CH-53E Super Stallion

Heavy transport and amphibious assault helicopter (first flown March 1974)

MH-53E Sea Dragon / S-80

Airborne mine countermeasures helicopter able to tow through water hydrofoil sledge carrying mechanical, acoustic and magnetic sensors; nearly 3,785 litres (1,000 US gallons; 833 Imp gallons) extra fuel carried in enlarged sponsons made of composites; improved hydraulic and electrical systems; minefield, navigation and automatic flight control system with automatic towing and approach and departure from hover modes.

CH-53K

Cargo, USN & USMC

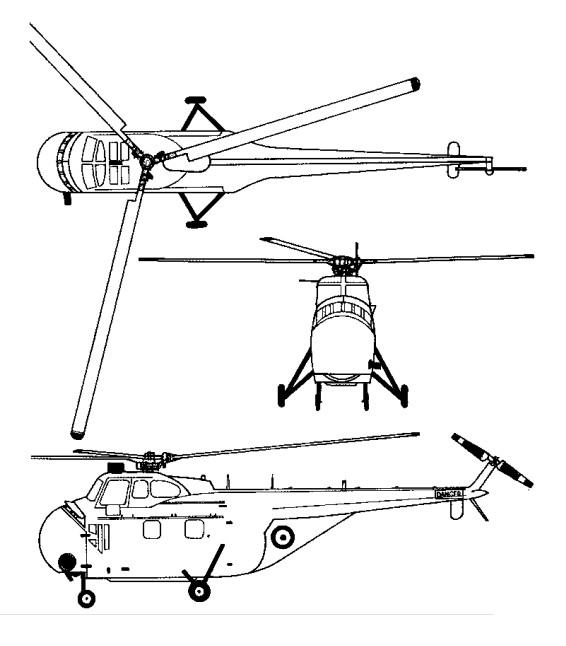

CH-53G

Version of the CH-53 for the German armed forces order for 135 examples, later reduced to 110, with T64-GE-7 engines. A total of 112 were produced, the first of two built by Sikorsky being delivered 31 March 1969. The next 20 were assembled in Germany by VFW-Fokker from US-built components, then progressively increasing indigenous sources. Prime contractor in Germany was VFW-Fokker, whose first CH-53G flew 11 October 1971, entered service in-1973. Deliveries completed in 1975.

YHH-53H

First aircraft to be fitted with ‘Pave Low I’, in trials for a projected night/ all-weather combat rescue/infiltration mission; fitted with early low-light TV system which proved inadequate, though the first successful night rescue was made with an improved system in December 1972, in Laos; aircraft later modified to ‘Pave Low II’ standard, with external sponsons and tanks

HH-53H

Eight HH-53Cs and YHH-53H modified to definitive ‘Pave Low III’ standard; delivered between 1979 and 1980 and fitted with FLIR, TF radar, INS, computer generated moving map display, RHAW and chaff/flare dispensers. Eight converted to MH-53J Pave Low III.

MH-53H

Redesignation and modification of HH-53H under the Constant Green programme; all ‘Pave Low III’ aircraft were modified to MH-53J standard

MH-53J Pave Low III Enhanced

US Air Force upgrade of Special Operations Forces combat rescue and recovery fleet; 31 HH-53Bs, HH-53Cs and CH-53Cs converted at NAS Pensacola, Florida, beginning 1986, to MH-53J Pave Low III Enhanced; similar to 11 HH-53H Pave Low III produced earlier, eight survivors of which also converted to MH-53Js; programme completed in 1990. Modifications include Texas Instruments AN/AAQ-10 nose-mounted FLIR, inertial navigation, Doppler radar, computer-projected map display, Navstar GPS, Texas Instruments AN/APQ-158 terrain-following/avoidance radar in offset nose radome, chaff/flare dispensers, Loral AN/ALQ-157 IR jammer on each outrigger pylon, 454kg of extra titanium armour plating and Collins AN/AIC-3 intercom; armament includes three 7.62mm or 12.7mm machine guns firing through windows on each side and from open rear ramp. Power plant is two 3,266kW General Electric T64-GE-415 turboshafts; maximum T-O weight increased from 19050 to 22,680kg. Further upgrades planned to improve combat effectiveness and service life. Those modified from HH-53Bs retain braced external tank pylons of first Super Jollys.

MH-53M Pave Low IV

Internal upgrade featuring new avionics and defence aids, including an integrated AP-102A weapon systems computer to speed up target acquisition. All 39 existing MH-53J Pave Low III’s are expected to be converted.

S-80E

Export version of CH-53E.

S-80M

Export version of MH-53E; total of 11 delivered to Japan for Japanese Maritime Self-Defence Force (JMSDF).

Yasur 2000

Upgrade of 30 Israeli Air Force CH-53Ds by IAI. Improved avionics and structural changes to extend service life. Other modifications include internal auxiliary fuel tanks, flight refuelling boom, rescue hoist, crashworthy seats and cockpit armour.

Detailed description refers to CH-53E, but applicable also to MH-53E and S-80 export versions, except where indicated.

COSTS: US$24.36 million (1992) projected average unit cost.

DESIGN FEATURES: Fully articulated seven-blade main rotor; blade twist 14°; hydraulic powered blade folding for main rotor; tail pylon folds hydraulically to starboard; four composite-blades tail rotor on pylon canted 20° to port to derive some lift from tail rotor and extend CG range; cranked, strut braced tailplane; rotor brake standard; fuselage stressed for 20 g vertical and 10 g lateral crash loads.

FLYING CONTROLS: Fully powered, with autostabilisation and autopilot. See also Current Versions and Avionics.

STRUCTURE: Fuselage has watertight primary structure of light alloy, steel and titanium; glass fibre/epoxy cockpit section; extensive use of Kevlar in transmission fairing and engine cowlings; main rotor blades have titanium spar, Nomex honeycomb core and glass fibre/epoxy composites skin; titanium and steel rotor head; Sikorsky Inflight Blade Inspection Method (IBIM) sensors detect blade spar cracks occurring in service; tail rotor of aluminium; pylon and tailplane of Kevlar composites.

LANDING GEAR: Retractable tricycle type, with twin wheels on each unit. Main units retract into rear of sponsons on each side of fuselage. Fully castoring nosewheels.

POWER PLANT: Three General Electric T64-GE-416 turboshafts, each with a maximum rating of 3,266kW for 10 minutes, intermediate rating of 3,091kW for 30 minutes and maximum continuous power rating of 2,756kW. Transmission rated at 10,067kW for take-off. Retrofit underway with 3,539kW T64-GE-419 turboshafts.

Self-sealing bladder fuel cell in forward part of each sponson, each with capacity of 1,192 litres. Additional two-cell unit, with capacity of 1,465 litres, brings total standard internal capacity to 3,849 litres. (Total internal capacity of MH-53E is 12,113 litres)

Optional drop tank outboard of each sponson of CH-53E, total capacity 4,921 litres. (MH-53E can carry seven internal range extension tanks, total capacity 7,949 litres) Forward extendable probe for in-flight refuelling. Alternatively, aircraft can refuel by hoisting hose from surface vessel while hovering.

ACCOMMODATION: Crew of three. Main cabin of CH-53E will accommodate up to 55 troops on folding canvas seats along walls and in centre of cabin or 24 litters. Door on forward starboard side of main cabin. Hydraulically operated rear-loading ramp. Typical freight loads include seven standard 1.02 x 1.22m pallets. Dual and single-point central hooks for slung cargo, capacity 16,330kg.

SYSTEMS: Hydraulic system, with four pumps, for collective, cyclic pitch/roll, yaw and feel augmentation flight control servo mechanisms; engine starters; Engine Air Particle Separators (EAPS); engine and hydraulic oil replenishment in flight; landing gear actuation; cargo winches; loading ramp; and blade and tail pylon folding. System pressure 207 bars, except for engine starter system which is rated at 276 bars. (Separate hydraulic system in MH-53E to power AMCM equipment.) Electrical system includes three 115V 400Hz 40 to 60kVA AC alternators, and two 28V 200A transformer-rectifiers for DC power. Solar APU.

AVIONICS: Flight: Hamilton Standard automatic flight control system, using two digital onboard computers and a four-axis autopilot. Retrofit test flown late 1993, comprising four Canadian Marconi CM A-2082 15.2cm square colour displays, tied with GPS, Doppler and AHRS; installation by Teledyne Ryan.

EQUIPMENT: MH-53E equipment includes Westinghouse AN/AQS-14 towed sonar, AN/AQS-17 mine neutralisation device, AN/ALQ-141 electronic sweep and Edo AN/ALQ-166 towed hydrofoil sled for detonating magnetic mines.

ARMAMENT: Window mount provisions for 7.62mm and 12.7mm weapons.

Specifications:

YCH-53A Sea Stallion

Engines: two T64-GE-6

Max speed: 200+ mph

No built: 2

S-65A

Engines: two 3925hp T64-GE-413 turboshafts

Rotor: 72’3″

Length: 67’2″

Max speed: 196 mph

Range: 257 mi

Crew: 3

Passenger capacity: 41

CH-53A Sea Stallion

CH-53D

Engine: 2 x General Electric T64-GE-412 turboshaft, 2926kW / 3,925 shp

Main rotor diameter: 22.02m

Disc Area: 280.5 sq.m

Fuselage length: 20.5m

Height: 7.6m

Max take-off weight: 19050kg

Empty weight: 10650kg

Max speed: 315km/h

Cruising speed: 278km/h

Range with payload: 2075km

Rate of climb: 11m/s

Service ceiling: 6220 m / 21,00 ft

Internal (external) payload: 3710kg (9070kg)

Accommodation: 37 troops or 24 stretchers

RH-53D / NRH-53D Sea Stallion

Engines: two T64-GE-415

YCH-53E Super Stallion

Engines: 3 x GE T64-GE-415, 4380hp turboshafts

Main rotors: 7

Rotor dia: 24.08 m (79 ft 0 in)

Length 73’9″

Max speed: 195 mph

Cruise: 172 mph

Range: 306 mi

Ceiling: 18,500′

CH-53E Super Stallion

Engine: 3 x General Electric T64 416 tur¬boshafts, 4380 shp (3266 kW)

Rotor dia: 24.08 m (79 ft 0 in)

Fuselage length: 22.3 m

Length overall 30.19 m (99 ft 0.5 in)

Height: 8,66 m (28 ft 5 in)

No blades: 7

Main rotor disc area 455.38 sq.m (4,902.0 sq ft)

Empty wt: 15071 kg (33,226 lb)

MTOW: 33339 kg (73,500 lb)

Payload: 14,515 kg

Max speed: 170 kt

Cruising speed at sea level 278 km/h (173mph)

ROC: 840 m/min

Fuel cap (aux): 4920 lt (4545 lt)

Max range (unrefuelled): 2075 km

Range: 56 mi with 16 tons external cargo

Range: 575 mi with 10 tons external cargo

HIGE: 11,550 ft

HOGE: 9500 ft

Ceiling: 5640 m / 18,500′

Crew: 3

Pax: 55

CH-53G

Engines: 2 x T64-GE-7

Fuselage length: 67 ft 3 in (20.5m)

Pax cap: 38 troops

HH-53 Jolly Green Giant

Engines: 2

Fuselage length: 67 ft 3 in (20.5m)

Pax cap: 38 troops

HH-53B Super Jolly

Engines: 3080hp T64-GE-3

Seats: 6

No built: 8

MH-53E Sea Dragon

Engine: 2 x GE T64-416, 4380hp

Instant pwr: 3263 kW

MTOW: 33,340 kg

Payload: 16,587 kg

Max speed: 170 kt

Max range: 2035 km

Ceiling: 27,900′

HIGE: 3520 ft

HOGE: 2895 ft

Crew: 3

Pax: 55

MH-53J PAVE LOW IIIE

Engines: two 4330hp GE T64

Main rotor: 72’0″

Length: 92’0″

Max take-off weight: 46,000 lb

Max speed: 165 mph

Range: 630 mi

Ceiling: 16,000′

Accommodation: 8

RH-53D

Engines: 2

Fuselage length: 67 ft 3 in (20.5m)

Pax cap: 38 troops