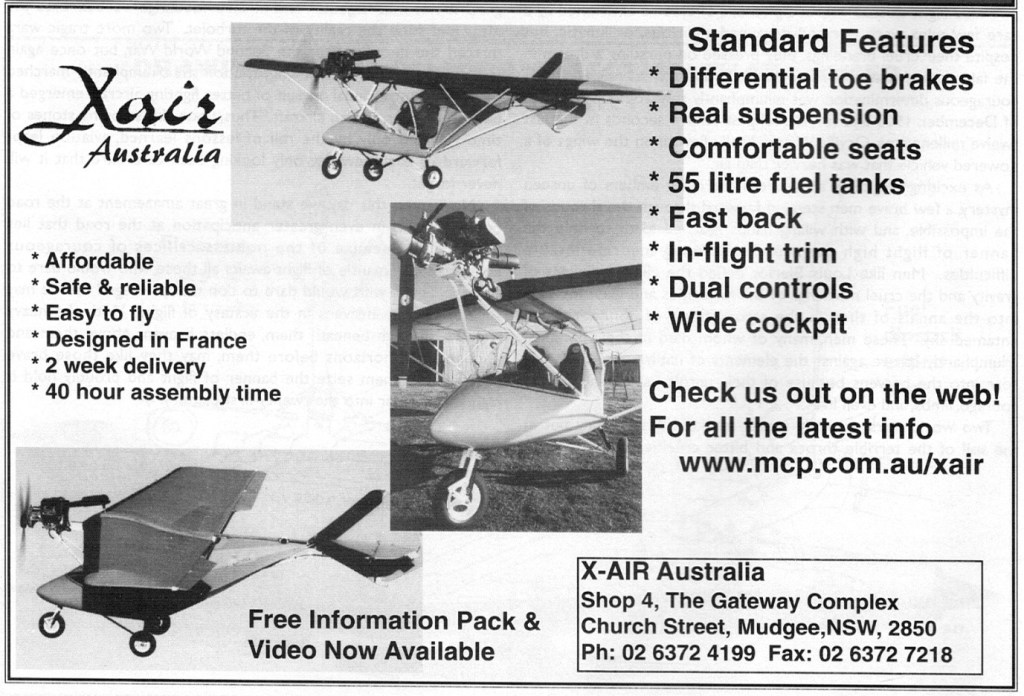

The “F” model or “FLAP” model is an evolution of the standard X-Air; it has three stage flaps to slow the aircraft down for landing and more streamlined fuselage section. The wing and tail on the Flap model also differs from the Standard X-Air, the flap model flies faster than the standard X-Air because of the different profile wing.

The kit is essentially the same.

The upgraded design gives an improved cruise speed, and makes handling in rough weather even better.

The X-air Falcon also known as the Xair-F in some countries, has the same configuration as the standard Xair, high wing, 2 side by side seats, dual controls, the pilot has toe brakes, elevator trim etc. as the Xair, with the addition of a 3 stage flap. The X-AIR can also be fitted with an emergency brake operated by the instructor. The X-Air also has a solid wooden floor in the cockpit.

The maximum all up weight of 450kg is the same, but has an improved wing profile which is shorter in span and cord. The wing section is now also fully double surfaced to the root and the fuselage tail section extends to the rudder post.

The Falcon is manufactured in India, and is supplied in kit form, which comes very complete. Only the choice of Engine/Prop & Instruments are required to finish it, ready for flight.

The X-Air can be pulled down in about 15 minutes. Firstly, the Velcro attached wing nappy is removed, the wing skin tensioning belts are released, the aileron cable is detached and with the assistance of a helper the wing struts are removed and finally, the wings are detached from the main fuse tube. All the wing removal can be done without tools. The wing can be reattached in about 25 minutes.

Nearly all of the exposed tubing, comes White Epoxy painted for long life. Some components come pre-assembled, e.g. Tailplanes & Elevators, and all the required nuts & bolts are in their relevant place’s, to speed up assembly.

The Falcon like the X-air is fitted with full Dual controls, i.e. two sticks, two throttles. The advantage of being in the left seat is to use of the independent toe brakes, fitted to the top of the Rudder pedals.

The seating is fitted with headrests. The cockpit floor is solid, and there is an optional door kit. Each wheel has its own shock absorbing system. The suspension design is similar to shock absorbers on a motorcycle and can handle all the bumps and potholes on grass and bush strips with ease. The front wheel has dual shock suspension with trailing link design steering; the trailing link design straightens up immediately on touch down, so even landing in cross wind is relatively easy in the X-Air. The shock absorber design used on the X-Air offers rebound dampening. The undercarriage is rated to 9 g’s.

Structurally the Falcon has been tested, at it’s all up weight of 450kg, to 6 Gs positive and 3 Gs negative.

The flap model X-AIR were available with three engines from Rotax-Bombardier of Austria, the Australian produced Jabiru engine and the HKS from Japan. Available Rotax options being the 52 HP “503” or the 65 HP “582” and the 80HP “912”. All Rotax engines feature carbon fiber Brolga ground adjustable props.

The fuel tank capacity of just over 59 liters gives a comfortable endurance of at least 3 hours at normal cruise with a 1/2 hour reserve and the optional 80 L fuel tank was available.

The Jabiru engine produces 80 horsepower and consumes approximately 15 liters of fuel per hour and the HKS engine has been successfully fitted to several aircraft.

The recommended engine selection is the Rotax 582. The 582 engine bolts to the X-Air without modification, it provides up to 1200 ft/min climb one up, 900 to 1000 ft/min climb two up). The Rotax 503 climb performance is about 600 ft/min.

General Configuration

Two seater, side by side

3 Axis; Ailerons, elevator and rudder

Full dual control – two sticks, two throttles

High wing, high mounted engine

Tricycle Gear, with independent hydraulic shock absorbers

Steerable nose wheel, linked to rudder pedals

Toe operated differential brakes

Enclosed cockpit, lexan windscreen

Enclosed fuselage

Elevator trim

3 stage Flaps

Two 27L Tanks

Polyester Sail Cloth

G loading +6 -3

6061 T6 Alluminium

Tubing epoxy/polyurethane painted

X-Air F

Engine: Rotax 503

Length: 5.70 m / 18 ft 8 ins

Wing span: 9.45 m / 31 ft

Max height: 2.55 m / 8 ft 4 ins

Wheel track: 1.60 m / 63 ins

Wing area: 14.28 sq.mWheel track: 1.60m

Wheel base: 1.45m

Wheel size: 500 mm / 16 ins

Wheel base: 1.45 m / 57 ins

Empty weight: 230-251 kg

Empty weight w/opts: 242-279 kg

Engine: Rotax 582 ‘C’ Box engine fitted with two blade DUC Prop

Length: 5.70 m / 18 ft 8 ins

Wing span: 9.45 m / 31 ft

Max height: 2.55 m / 8 ft 4 ins

Wheel track: 1.60 m / 63 ins

Wing area: 14.28 sq.m

Wing loading: 31.50 Kg/sq.m

Wheel size: 500 mm / 16 ins

Wheel base: 1.45 m / 57 ins

Empty weight: 237-270 kg

MTOW (Australia): 490 kg

582DCDI

Stall Speed: 28 mph

Vne: 98 mph

Cruise Speed: 70 mph

Climb Speed: 40 mph

Rate of Climb: 700 ft/min

Glide Ratio: 7@40 mph

Fuel Consumption: 16 Ltr/hr

Empty weight: 237-270 kg

MTOW (Australia): 490 kg

X-Air F

Engine: Rotax 618

Length: 5.70 m / 18 ft 8 ins

Wing span: 9.45 m / 31 ft

Max height: 2.55 m / 8 ft 4 ins

Wheel track: 1.60 m / 63 ins

Wing area: 14.28 sq.mWheel track: 1.60m

Wheel base: 1.45m

Wheel size: 500 mm / 16 ins

Wheel base: 1.45 m / 57 ins

Empty weight: 230-251 kg

Empty weight w/opts: 242-279 kg

Jabiru

Engine: Jabiru fitted with Newton 2 blade wood 60″ x 40″.

Empty weight: 263kg/580 lbs

Stall Speed: 32 mph

Vne: 98 mph

Cruise Speed: 75 mph

Climb Speed: 40 mph

Rate of Climb: 700 ft/min

Glide Ratio: 7@40 mph

Fuel Consumption: 11 ltr/hr

MTOW (Australia): 490 kg

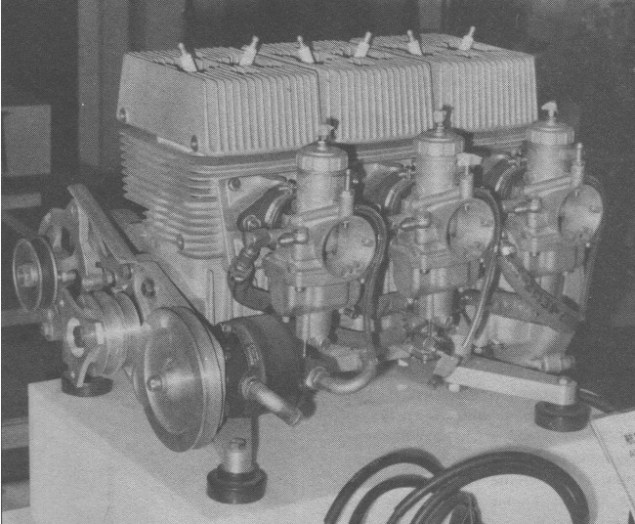

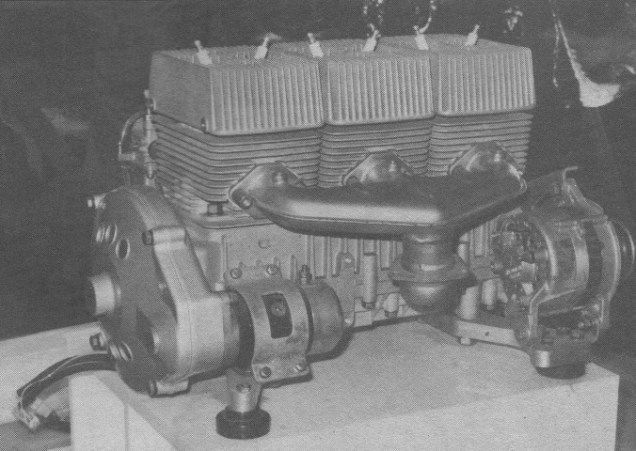

Verner 133M

Engine: Verner 133M 2:1 box fitted with 2 blade DUC prop.

Stall Speed: 32 mph

Vne: 98 mph

Cruise Speed: 80 mph

Climb Speed: 40 mph

Rate of Climb: 800 ft/min

Glide Ratio: 7@40 mph

Fuel Consumption: 11 ltr/hr

MTOW (Australia): 490 kg

Empty weight: 263kg/580 lbs