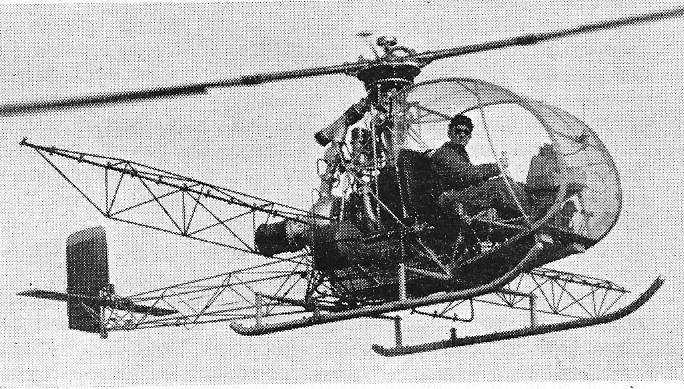

On 17 January 1991, the Tridair Gemini ST twin engine conversion of the Bell 206L LongRanger took to the air for the first time. The Gemini ST was designed to take off and hover at gross weight at sea level on one engine; the only twin engine helicopter that will have no written procedures for a single engine failure on takeoff.

The inspiration for the Gemini ST came to Doug Daigle, president of Tridair Heli¬copters in Costa Mesa, California, in 1986 when he successfully bid on a US Forest Service contract for a Bell LongRanger to be used as a rappelling platform for fire¬fighters.

This was the first time a single engine helicopter had been awarded this contract. The work had previously been done by a Bell 212, but this aircraft had become very expensive to contract, leading the Forest Service to look at the safety records of single engine helicopters and find the Bell LongRanger’s to be outstanding.

After Doug Daigle rappelled out of the helicopter to see what the fire crew would experience (an act he regrets to this day), he concluded that if the engine failed while the crew was rappelling, they would prob¬ably die. Even using a 212, the crew on the rope would be severely injured or killed. The 212 might be able to recover, but the team on the rope would be dragged through the trees or rocks. Mr Daigle then decided to try to design a twin engine conversion for the Bell LongRanger. While several people, includ¬ing from Bell Helicopter, had the same idea in the past, he took a different approach in wanting to design a helicopter that would take off on one engine at sea level at gross weight. The Bell TwinRanger project in¬volved a complete redesign that would weigh almost 1,500 lb more than the LongRanger, weight that caused the project to be shelved.

The first major obstacle overcome for the project was in 1988 when the FAA awarded the programme a grant of exemption. FAA regulations state that any time the number of engines or rotors is changed a new Type Certificate must be obtained. This would have cost many millions of dollars. The only time an exemption can be issued is for public safety and/or public economics. The Gemini qualified on both grounds.

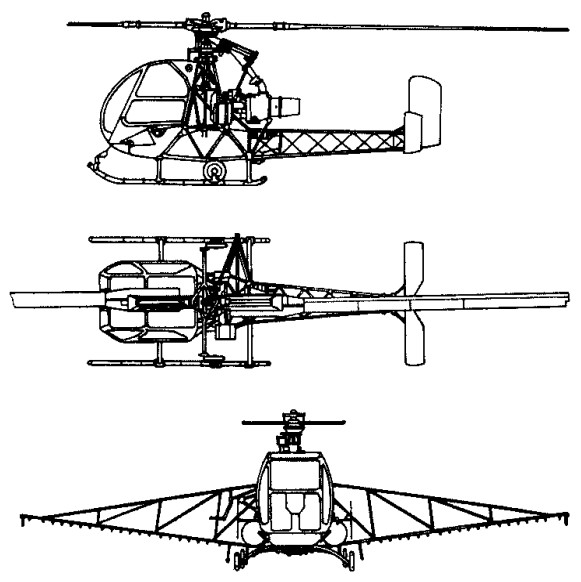

Internally, the Soloy Dual Pac gearboxs have independent dry sump system utilising two oil pumps built into the gearbox case. Freewheel Units One unit each for left and right drive trains, ensuring minimum drag during single engine operation. Mounting System Combination of engine and gearbox mount pads used to secure the engines/gearbox assembly to the airframe. With one engine shut down, only the gearbox on the side that is running turns. If there is a catastrophic failure on one side it will not interrupt power from the good side.

Separate fuel systems for each engine had to be installed. The conversion also demanded a new cowling that incorporates dual oil coolers, blowers, and oil reservoirs.

The flight testing process began in February 1991.

The Gemini ST was certified by the US FAA to operate on one or both engines in all phases of flight.

206L-3ST Gemini ST

Engine: 2 x Allison 250-C20R

Instant pwr: 335 kW

Rotor dia: 11.3 m

MTOW: 1820 kg

Payload: 570 kg

Max speed: 130 kts

Max cruise: 110 kts

Max range: 745 km

HIGE: 10,000 ft

HOGE: 6,900 ft

Service ceiling: 10,000 ft

Crew: 2

Pax: 6

Seats: 8

206L-3ST Gemini ST

Engine: 2 x Allison 250-C20R

Instant pwr: 335 kW

Rotor dia: 11.3 m

MTOW: 2020 kg

Payload: 770 kg

Max speed: 130 kts

Max cruise: 110 kts

Max range: 465 km

HIGE: 20,000 ft

HOGE: 16,400 ft

Service ceiling: 20,000 ft

Crew: 2

Pax: 6

Seats: 8

BELL SDP H500A 206L 3ST

Engines: 2 x Allison 250 C20R, 435 shp each

Gearbox ratings Input (each side) 450 shp, Output 500 shp

Seating: 7

Fuselage Length: 33ft 2.6in

Overall Length: 42ft 8.5in

Overall Height: 10ft 3.8in

Rotor Diameter: 37ft

Blades: 2 x semi rigid teetering all metal

Max. Gross Weight: 4,450 lb

Empty Weight: 2,590 lb

Useful Load: 1,860 lb

W/full fuel: 1,110 lb

Max External Load: 2,000 lb

Vne: 150 mph

Cruise: 135 mph

Max. Rate of Climb: 1,340 fpm

Fuel Capacity: 750 lb 110 USgal

Avg. Fuel Consumption: Single Engine 26 USgph, Twin Engine 42 USgph

HIGE: 16,500 ft

HOGE: 7,500 ft

Service Ceiling: 20,000 ft