Developed from 1992, the Elite is a 10 seat highly modified version of a Sikorsky S-55. One development aircraft was registered N2650M.

Engine: Garrett TSE331, 700hp

Useful load: 2500 lb

Max speed: 114 mph

Range: 325 mi

Developed from 1992, the Elite is a 10 seat highly modified version of a Sikorsky S-55. One development aircraft was registered N2650M.

Engine: Garrett TSE331, 700hp

Useful load: 2500 lb

Max speed: 114 mph

Range: 325 mi

A single-rotor combined autogyro/helicopter based on 1936 Nagler VG-1.

USA

Founded March 1970 by Bruno Nagler to build Vertigiro VG-2, single-rotor combined autogyro/helicopter based on 1936 Nagler VG-1. VG-2P prototype and VG-2C production model were never manufactured, but in March 1971 Nagler formed Nagler Aircraft Corporation, starting on completely new projects.

The Hummingbird helicopter kit programme began in 1988. A 4 place helicopter based on a Sikorsky S-52. Of aluminium construction with carbon-graphite composite nose, powered by an aluminium 6.5 lt V8 of 260hp. Rotor mechanics remained the original.

By 1995, equipped with an electric cyclic trim system and hydraulic driven radiator fan. This helicopter was still available in fit form in 2004.

After a break in production of six years the company produced a new and improved Hummingbird in 1991, the 260L.

The Hummingbird 260L is a highly modified version of the four place Sikorsky S 52¬-3 with major changes to the nose, windshield, and powerplant installation turned into a kit. A modification has been the installation of a 260 h.p. Lycoming powerplant. The Hummingbird 260L is an FAA approved helicopter combined with an FAA approved powerplant. The Lycoming VO 435 A1F was designed to operate in an oblique position. One version can be turbo charged to 280 h.p. The Lycoming VO 435 A1F can be operated with automobile gasoline making it “fuel friendly”, where Avgas availability is limited. This entire powerplant installation was designed to meet the requirements of FAR 27 regulation standards for all helicopters in the Western world.

Another change to the new Hummingbird is the composite cabin doors and vertical/ horizontal stabilisers. The tail stabilisers were designed to increase lateral and longitudinal stability, increase tail rotor effectiveness, and reduce weight on the tail of the helicopter. Most components have a time/life of 1200 hours. New blade design will most likely extend blade life to 2000 hrs. A set of three main rotor blades costs about a third of the price of those for a comparable four place piston engine helicopter, with the total aircraft price less than half. The Hummingbird has strength inherent in its basic design. With a payload of over 900lbs, it will take a good size sling load, and with a quick removal of the rear seats, the “utility” configuration means bulky cargo can be carried. Also long range fuel tanks have just been designed as an extra.

As a Kit, the helicopter fits into the Amateur Built/Experimental Category and most of the maintenance can be done by the owner/assembler.

The Hummingbird is a single engine, single three-bladed main rotor type helicopter, with a tail rotor. The fuselage is made of aluminum and composites. The Hummingbird is powered by a FAA approved Lycoming aircraft engine. The transmission system consists of a clutch/freewheel unit between the engine and main gearbox, a main driveshaft extending from the top of the main gearbox to the main rotorhead, and a take-off drive from the main gearbox which drives the tail rotor driveshaft, intermediate gearbox and tail rotor assembly. These parts are manufactured to FAA design standards.

The Hummingbird cabin sits four people. The cabin is 55 inches wide, 56 inches high from floor to ceiling, and 110 inches in length. Two baggage areas 15” L x 20” W x 13” H are located under the forward two seats. Fly two people, 375 miles, with 220 lbs. of camping gear.

The many prefabricated components of the Hummingbird 260L make the kit an easy project for the first time builder. The average build time is 800 hours. There is no welding or composite work, only minor fabrication, and all major components are pre-assembled. The rotor blades for example come to you painted, balanced, and ready for installation. These blades have 7 degrees of twist to enhance performance.

The Hummingbird helicopter kit is assembled in 14 easy to follow sections. The first section consists of building the lower cabin. In this section, you will learn about real aircraft sheet metal fabrication and aircraft assembly. In the next section you will receive the upper cabin assembled.

After fitting the upper and lower cabin together, the landing gear is next, and then the nose. Flight controls, electrical components, instrumentation and fuel systems are next for installation.

The tailcone section is supplied assembled to assure uniformity. The powerplant and gearboxes are assembled for installation when received.

The main rotor blades and tail rotor blades will then come to you completely ready to install in the fully articulated rotor head. They will have been painted and pre-balanced at our factory. After rigging all the flight controls and cables, and calculating the Hummingbird’s weight and balance, it’s ready to fly.

Because of its inherently long tail, forward flight is very stable but very agile. The flight control system incorporates electric trim with force gradient spring pressure. Stick forces are very light. An appealing characteristic is the landing gear that is able to taxi and not have to hover, with hydraulic brakes and shock absorbing struts. The three blade rotor system is very smooth and has a medium inertia rotor providing excellent autorotation characteristics. The clutch is automatic for engaging the rotor system and a rotorbrake is included to slow the rotor during shut down.

Hummingbird

Engine: Aluminium V-8, 260 hp

hp range 260-315

Empty wt: 1,800 lb

Max wt: 2,700 lb

Rotor span: 33ft

Length: 30’6”

Height: 8’2”

Width: 8’7”

Service Ceiling: 11,000 ft

Max speed: 110 mph

Cruise: 90-95 mph

Range: 450 sm

Seats: 4

ROC: 1200 fpm

Fuel cap: 57 USG

Hummingbird

Engine: V8 6.5 lt, 260 hp

Rotor span: 10.05 m

MAUW: 1223 kg

Empty weight: 815 kg

Fuel capacity: 215 lt

Max speed: 176 kph

Cruise speed: 150 kph

Minimum speed: 0 kph

Climb rate: 4.75 m/s

Seats: 4

Fuel consumption: 50 lt/hr

Kit price (1998): $140,500

Hummingbird 260L

Engine: Lycoming V0-435

Rotor Blades: 3-blade

Main rotor dimension 33′ 0″

Tail rotor dimension 5′ 9″

Fuselage length 30′ 6″

Height 8′ 7″

Width 5′

Empty Weight 1,800 lbs

Useful Load 900 lbs

Gross Weight 2,700 lbs

Fuel 57 USG

Min Speed Hover

Vne 132 mph

Cruise 90-95 mph

Top Speed 110 mph

Rate of climb 1250 fpm at 2300 lb

Rate of climb 950 fpm at 2700 lb

Service ceiling 14,000 ft

Range 375 Miles

Kit: $169,000 in 2009.

Seats: 4

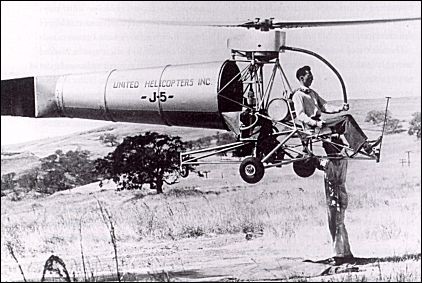

Founded 1988. Under took repair of Sikorsky and Orlando helicopters; modifies Sikorsky S-55 helicopters for various uses including agricultural, passenger carrying, assault, heavylift, camping, computerised aerial advertising, and training (latter Aggressor, reconfigured to appear as a Russian Mi-24); and offers a modernized version of the four-seat Sikorsky S-52-3 helicopter, known as Hummingbird and sold in kit form.

Vertical Aviation Technologies, Inc. has principle offices and facilities at Orlando Sanford International Airport, Sanford, Florida. The company is engaged in research, design and manufacturing of helicopters worldwide from our four passenger Hummingbird helicopter kit to the nine passenger Sikorsky Whisper Jet quiet technology helicopter.

1996-2009: PO Box 2527, Sanford, FL 32772-2527, USA.

1998-2008: Vertical Aviation Technologies, Inc., 1609 Hangar Road, Sanford, FL 32773, USA.

The success of the H3 version resulted in the construction of a follow-on 1969 H5 prototype which bore marked similarities to its predecessor. The H5 incorporated many H3 components, including rotor blades (although 0.6m longer), a modified H3 landing gear, along with H3 controls, tail, and tail boom. The cabin could also be opened with left-side seats capable of folding for litter loading and unloading. The larger H-5 cabin had five seats.

Like the H3, there was also no hydraulic system with the H5.

It was intended that the H-5 would be followed by the H-7 7/8 seater (construction of which was apparently started but not completed) and the much larger H-9. As it turned out, however, further development was abandoned in 1972 following the merger of VFW and Fokker.

In 1960 VFW began research to develop a VTOL concept that exceeded the capabilities of current helicopters. More than a dozen different concepts were investigated, and the concept that evolved promising the best growth potential, productivity, speed, and cost effectiveness was the H3-E Compound Helicopter configuration.

The H3-E was built with a mission as a three-seat executive transport, two-stretcher ambulance aircraft, or an agricultural system with a payload of up to 315kg.

The design incorporated a compressed air and blade tip-drive rotor. The separate forward-thrust system consisted of fuselage-mounted fans.

The H3-E had a take-off weight of about 950kg and an empty weight of 500kg. The craft provided a payload weight of 265kg. The model had the capability of carrying a payload of almost 270kg with a fuel load of 205kg.

The completely enclosed fuselage was built around an aluminum alloy load-bearing keel which supported the cabin, landing gear, and engine bay structure, low-set tailboom with a V-tail, and a tricycle undercarriage. The cabin skin was fabricated of a glass-fiber reinforced plastic laminate.

The power unit was an Allison 400 shaft horsepower turbine engine which had a dual purpose. First, it was used to drive a centrifugal compressor in the hover mode. A duct delivered the compressed air through a flexible sleeve to the air distributor around the rotor shaft. Then, the high-pressure air traveled via flexible hose into the roots of the fully-articulated blades.

The overhead rotor consisted of a three-blade configuration and the blades used the NACA 23015 airfoil section. The speed range for the rotor varied from 280 to 480 revolutions per minute with a maximum loading of 15.7kg/sq.m.

When the air reached the end of each rotor, it was thrust through flush-mounted slot nozzles. A gearbox contained two bevel gears for the fans and a brake on the compressor shaft for switching the power to the compressor or to the fans. The mechanical layout of the system effectively eliminated the need for conventional transmission and driveshaft systems, hydraulic systems, and a tail rotor.

The technique to achieve near-vertical flight occurred when the rotor was slightly rotated in a standard helicopter style. With the increase in speed, the side-mounted fans were caused to free-wheel within their containing shrouds.

At a certain point in the trajectory, a decision that was made by the pilot, the transformation to full utilization of the fans could be made. Since the fans were already in a windmilling situation, the transition to full fan speed took only about two seconds to accomplish.

Hovering stability was mainly affected by blade hinge offset, blade pitch, angular velocity, disk loading, gross weight and mass moment of inertia of the aircraft,

Early in its program the H3-E underwent a number of test programs. An extensive blade fatigue test attempted to simulate the temperature and pressure cycles inside the blades. The test rig was fully automated, and every five minutes, the temperature and pressure increased and stabilized for 45 seconds before the blade vibrated.

The only two prototypes of the H3 were constructed in 1968. Before flight, though, there were considerable ground shake tests accomplished. A sophisticated test rig excited the rotor head with a constant force independent of frequency. Ground tests also showed that the vehicle had certain mechanical instabilities at high rotor speeds. The first of two prototype H-3s (H3-E1, D-9543) flew in early 1970 without the external fan propulsion units.

Engine: 1 x Allison 250-C20 turboshaft, 300kW

Main rotor diameter: 8.70m

Rotor disc area: 60 sq.m

Length with rotors turning: 9.29m

Max height: 2.5m

Landing gear track: 2m

Max take-off weight: 968kg

Empty weight: 495kg

Max speed: 300km/h

Max cruising speed: 250km/h

Normal cruising speed: 242 kph

Max vertical rate of climb: 2m/s

Service ceiling: 3900m

Endurance: 2hr

Australia

Predecessor of VTOL Aircraft, developing Phillicopter.

Single-seat helicopter built by Y.Valunas in 1984, Prenai, Lithuania. Reportedly never flew.

To counteract torque this two-bladed-rotor experimental helicopter used not a conventional tail rotor but a jet thrust system. The latter consisted of a fan blower placed just behind the engine with a ‘stove pipe’ tail forward. Air was thus forced under pressure through the hollow fuselage into a tail orifice where vanes directed the jet thrust laterally.

Main rotor torque was effectively overcome, but this torque compensation system’s power requirements proved markedly excessive at speeds greater than 64km/h. Single-seat experimental helicopter with open frame front mounting pilot and engine and metal cone tail with jet thrust duct. One built.