1998-2009: Jim Montgomerie Gyrocopters

Kirkmichael Road, Crosshill,

Maybole, Ayrshire

Scotland KA197RJ

Gyrocopter builder

1998-2009: Jim Montgomerie Gyrocopters

Kirkmichael Road, Crosshill,

Maybole, Ayrshire

Scotland KA197RJ

Gyrocopter builder

AC.4 single-seat autogyro dated from 1970s as a design of Altair Coelho. Marketed by this company after purchase of rights and many sold in assembled and kit forms.

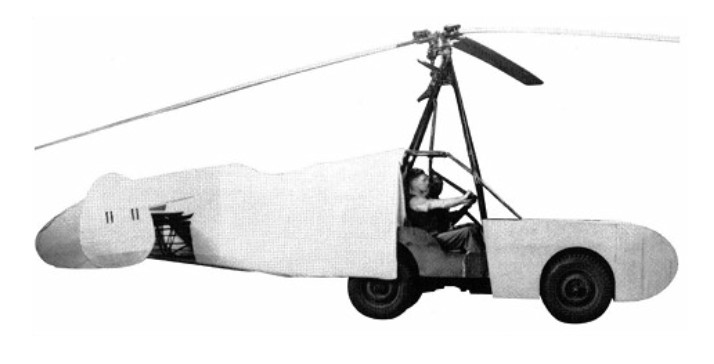

Raoul Hafner, an Austrian expatriate engineer, was working for the British Airborne Forces Research Establishment when he developed the idea of using free¬wheeling rotors to deliver airborne personnel into enemy territory. Having proved that his Rotochute could support a combat ready soldier, Hafner suggested that much heavier loads might also be delivered by rotor; a jeep, perhaps, or a truck, possibly a tank.

The scheme had a naive simplicity; take a vehicle, add a suitably sized rotor and tail surfaces, tow it to altitude behind an aircraft, then cast it free at the planned landing point for landing. M.L. Aviation at White Waltharn airfield in Berkshire, were awarded a development contract for the first Rotabuggy to Specification 10/42, which appeared in 1943. The basic vehicle was a US Army jeep, to which was attached a fuselage extension with a twin finned tailplane (no rudders), and a 14 m (46 ft 8 in) diameter rotor. The jeep was equipped with a rotor control column which hung from the roof, a rotor tachometer, and a rudimentary set of flight instruments, but was otherwise quite standard. Preliminary tests were conducted with the Rotabuggy, or Rotajeep as it was otherwise known, ballasted with concrete to 1430 kg (3150 lb) and dropped from a height of about 2.1 m (7 ft) to test its impact absorption.

This demonstrated that the standard model could absorb impacts of 1lg without damage, and a two blade rotor with a diameter of 46 ft 8in (12.4 m) was then fitted.

Camouflaged in the wartime fashion and sporting a prototype “P” and RAF roundels, a 4½ litre super charged Bentley sports car was hitched to the jeep and towed the combination at speeds up to 105 kph (65 mph). The Rotabuggy becoming airborne for the first time on 16 November 1943. These trials took place at Sherburn-in-Elmet, near Leeds.

By November 1943 the Rotajeep was ready for air testing from Sherburn in Elmet airfield towed by a Whitley bomber. Seven flights were made, one flight crashed nearly killing the pilot. The combination made one very short circuit on the final flight.

Mary de Bunsen with the Air Transport Auxiliary witnessed one of the flights: “We all stood and watched while an old Whitley taxied out on to the runway and took off, with a jeep in tow. They made a very short circuit, and when the Whitley touched down, the jeep, which had not cast loose, remained airborne for some seconds a few feet above the runway. It was at this juncture that we realized that the occupants were unhappy. The pilot held the control column, which was directly connected with the rotor and was suspended from the roof. The driver sat beside him and held the steering wheel. Up and down, up and down, it wandered, white we all stood and prayed that it would stall on a “down” rather than an “up”. This it fortunately did, landing plop on all four wheels, and the motor driver took over and steered it down the track like Stirling Moss. When it stopped, nobody got out for a while, and then the pilot was assisted out and laid down flat beside the runway to recover. Apparently the joystick had whipped round and round in circles all the time they were in the air and only sheer strength had kept the jeep under control, so the poor man was completely exhausted.”

Not all the flights were as nerve shattering as this had apparently been. The handling and flying qualities of the Rotabuggy have been described officially as “highly satisfactory”, especially after larger fins had been fitted and greater blade articulation provided. However, the development of the Horsa and Hamilcar vehicle carrying gliders made further development of the idea unnecessary, before a 47.25 m (155 ft) rotor could be tested on a Valentine tank.

Rotabuggy

Rotor diameter: 12.40m

Gross weight: 1411kg / 3,110 lb

Empty weight – Jeep: 964kg

Weight – rotor unit and tail: 249kg / 550 lb

Design max speed: 241kph / 150 mph

Rates of descent – est: 4.9 – 10m/s / 960 1,980 fpm

Minimum take-off and landing speed: 58kph

Basic rotor speed: 230 rpm

Max rotor speed: 260 rpm

Crew: 2

The origins of M. L. Aviation began during the mid 1930s with two separate companies, mainely Wrightson Aircraft Sales (formed May 34). The name was changed to Malcolm and Farquharson (formed May 36) and again changed to R. Malcolm Company (founded in Dec 36). Malcolm & Farquharson became a holding company in December 1939 with aircraft product work carried out by R. Malcolm. About this time, Marcel Lobelle, who had been Chief Designer of Fairey Aviation joined the company. He had designed many Fairey aircraft including the Swordfish.

At the beginning of WW2, both Malcolm & Farquharson and R. Malcolm suffered financial problems and turned to the Mobbs family for assistance. During 1940, control of both companies was taken over by the Mobbs through United Motor Finance Corporation.

Under Marcel Lobelle, a drawing office was opened on the Slough Trading Estate (owned by the Mobbs family) with rapidly expanding work for the Ministry of Aircraft Production. To allow for expansion the drawing office and experimental work was moved to White Waltham, leaving production on the Slough Trading Estate and still under the name of R. Malcolm. An additional firing site was also established on the airfield perimeter for development work.

In 1943, Malcolm & Farquharson’s services were dispensed with and control was taken over by Eric Mobbs as Managing Director and Marcel Lobelle as Chief Designer. The company continued to trade under the name of R. Malcolm. Finally in October 1946 the name was changed to M. L. Aviation for the White Waltham site and M. L. Engineering at Slough, the initials presumably being taken from the leading figure heads.

Spurred on by the advent of the Cold War the company expanded rapidly from the 1950s with a considerable work force of Design Engineers designing and manufacturing a large range of aviation products.

Expansion required further finance and in 1958 M. L. went public through the creation on M. L. Holdings. Subsequently the Holding Company diversified with non-aerospace business introducing further finance and therefore gradually reducing the influence of the Mobbs family

The 1980s saw the reducing aerospace industry having considerable impact on MLA with an ever diminishing workforce until in 1990 the Holdings Board, having recently brought Wallop Industries based in Andover, deciding to merge and sell the White Waltham site. The move was completed by early 1991, leaving the Airfield test site still operating. The White Waltham site was eventually sold in 1996.

In mid 1996, the Holding Board acquired the remains of arch rivals Fraser Nash and merged it with MLA producing a formidable aircraft equipment company which should have augured well for the future.

M. L. (Engineering) in Slough finally moved to Andover in early 1997 enabling design and production to join under one roof, thereby almost severing links with Berkshire.

Finally Cobham plc acquired M. L. Aviation & Marine for £37 million.

Ted Minty designed Skyhook single-seat light autogyro, first flown 1978.

Mikhail Leontyevich Mil (died January 1970) began developing helicopters and autogyros in 1929. Mil was a contemporary of Nikolai Kamov at the TsAGI (Central Aero and Hydrodynamic Institute) during the 1930s, was given charge of his own design bureau in March 1947 and became responsible for the first Soviet helicopter to go into quantity production. The GM-1 / Mi-1.

Mi-1 first flown 1948, also manufactured by PZL-Swidnik in Poland 1956-1965. Mi-2 first flown in Soviet Union but production transferred to Poland. Enlarged Mi-4 introduced 1952, also built in China. Mi-6 with detachable wings to provide up to 20 percent of required lift in cruise flight first flown June 1957, then world’s largest helicopter, and 864 built at Rostov-on-Don (now Rostvertol) factory 1959-80, plus 50 at Moscow-Fili 1960-62. Mi-6 formed basis for Mi-22 airborne command post. Mi-8 first flown June 1961, becoming much produced medium civil and military helicopter (well over 7,000 built since 1965 and continuing), as turbine replacement for Mi-4; Mi-8 derivatives include Mi-9 tactical airborne command post (first flown 1977) and Mi-19 variant for use by commanders of tactical rocket units, Mi-17 (first flown August 1975) with change of engines and other modifications and Mi-171/Mi-172 export models, and lengthened Mi-173. Mi-10 flying crane development of Mi-6 first flown 1960, produced up to 1971. Two Mi-6 rotor/power packages used on giant Mi-12 with an overall rotors span of 67m, then the largest helicopter in world. Mi-14 became shorebased amphibious anti-submarine, SAR and mine-countermeasures helicopter (first flown August 1967).

Mi-26 first flown December 1977 as very heavy lift helicopter with two powerful turboshaft engines and single eightblade main rotor, with Mi-27 as airborne-command-post derivative. Series of helicopter gunships began with Mi-24 (first flown September 1969) and joining Soviet armed forces from 1970s, with Mi-25 as export version of Mi-24D tandem-cockpit variant and Mi-35 as second and improved export variant based on upgraded versions of Mi-24; most of over 2,500 built between 1970 and 1989, though smallscale production up to 1996. The Mi-28 attack helicopter was first flown November 1982. Mi-34 first flown November 1986 as piston-engined lightweight sporting and training fourseat helicopter. Proposed new types include Mi-40 eighttroop armoured and armed assault helicopter, Mi-46 heavy transport helicopter, Mi-52 three-seat light piston helicopter, Mi-54 utility helicopter, Mi-58 medium civil helicopter, and Mi-60MAI two-seat light training helicopter. Approximately 25,000 Mil helicopters have been built.

Became Mil Moscow Helicopter Plant. Has 25 percent shareholding in Euromil.

1995: (Moskovsky Vertolyotney Zavod), 2 Sokolnichyesky Val, Moscow 107113, Russia.

This single seat Autogyro was designed, built and tested by Jim Montgomerie, and is the result of continuous research and development over a 20 year period.

Based on the “Kit Build” airframe, it is constructed from aluminium alloy rectangular hollow section tubes. These tubes have been pre-drilled at Crosshill, and are fastened together with aircraft type approved fixings by either direct throughbolting, or in some cases braces with fillet plates which have been pre-drilled and cut to size with CAD laser technology and precision. The Merlin pilot enclosure will accommodate a pilot over 6 feet tall and is manufactured at Crosshill from polyester resin strengthened with E-glass and a Kevlar fibre reinforcing matrix.

The new developments that have been tried and tested on various aircraft over recent years, most done on the two seat autogyro G-BRFW. The Merlin comes with fully sprung and dampened main wheel suspension to reduce fatigue, and reduce the take-off run.

A modification to the Merlin is the alteration of the propeller thrust in relation to the centre of mass of the aircraft. The lowered thrust line passes directly through the centre of mass (depending on pilot weight and fuel load) of the aircraft to reduce the risk of a powered push over in the event of pilot mishandling.

This thrust line has been achieved by raising the engine further up the mast and turning the gearbox around to the down position with the propeller clearance maintained by incorporating a stepped joint in the keel tube.

Some minor modifications had also to be made to the nacelle to accommodate this new engine position with the exhaust passing through the nacelle to improve aerodynamic efficiency.

The Fuel Tanks are factory fitted behind the seat bulkhead area. The overall width to the outside of the Main wheel covers is 5’ l0” (1.800m) the height from floor to the highest point of the Gimbal Head is 7’5” (2.250m) and the overall length from nose to tail is 11 ‘6” (3.500m). Empty weight depends on the final specification and extras but the average is around 320lbs (145kg), which gives a useful payload of approx 3301bs (150kg) for pilot and fuel. Fuel capacity is approx 11 gal. (50ltr).

The original Merlin design holds the following endurance records:

1) First Autogyro to fly from Scotland to Ireland.

2) First Autogyro to fly from Ireland to Isle of Man.

3) First Autogyro to fly from Isle of Man to Mainland Britain.

4) First Autogyro to fly to all 5 Countries of the British Isle.

(Scotland, England, Ireland, Wales & Isle of Man) in one day.

Take off distance: 150ft (55m)

Landing distance: 0 to 65ft (0-20m)

Rate of climb: Over 900ft per min (275mpm).

VNE: 90mph.

Cruise: 75mph on 20 ltr. per hr.

A two-seat light autogyro, the actual prototype J-2, designed by D.K.Jovanovich, first flew in June 1962. Deliveries of production aircraft began in 1970 and by early 1972 a total of 83 had been built. Power was provided by a 180hp Lycoming O-360-A2D engine.

In 1974 Aero Resources took over production of the J-2 two-seat light autogyro from McCulloch Aircraft Corporation. A version known as the Super J-2 was developed from the J-2, powered by a 180hp Lycoming O-360-A2D flat-four engine.

The J-2 has a Hughes 300 three-blade rotor system (wind-driven and inverted) and is powered by a 180 hp Lycoming pusher engine. This gyro is capable of a “jump” lift-off with the aid of its powerful pre-rotator.

Aero Resources Inc assumed responsibility in 1974 for continued production of the J-2 gyroplane, designed by D. K. Jovanovich, and manufactured previously by McCulloch Aircraft Corporation. It also developed an improved version, with 200 hp engine, designated Aero Resources Super J-2.

The J-2 is now classified as a Class 2 Microlight (it was a full C of A Aircraft) so can be flown on Microlight Gyroplane Licence.

McCulloch J-2 Gyroplane

Engine: Lycoming 0-360 A2D 180 hp

Propeller: Hartzell 3 Blade Constant Speed

Rotor blades: 3

Seats: 2

Patrick Lewis

I am an ex US Army pilot and after a voluntary RIF in 1970 at the end of my second Vietnam tour emigrated to Australia. I worked for several helicopter companies there and was offered a position with Hawker de Havilland based at their Bankstown GA airport during the mid 1970s. HdH Had purchcased 8 J-2s and needed an experienced rotory wing instructor pilot for sales demonstrations and flight training. My first job was to draft a flight manual sylabus that satisfide The senior examiner. The first J-2 arrived with an instructor pilot who checked out HdHs test pilot who in turned checked me out. I then checked out the local rotory examinar who then signed me off as a qualified instructor. HdH mechanics outfitted a J2 with an extra fuel tank and I made sales demonstration trips from Melbourne in the south to the sheep stations in the Darwin area and on to the North west cattle stations.

Jeff Jacobs

In 1971 I was a young fixed-wing CFI working for Bel-Air Aviation at Long Beach CA, the first dealer and school for the J-2. I had no prior rotor experience but was being trained to fly and instruct in the J-2.

I had soloed the J-2 a few weeks earlier, and on 5/5/71 my boss and instructor Ken McGuire and I flew N4303G from Long Beach to Compton for more practice. We touched down in a light crosswind, and despite the slow speed I lost directional control and the aircraft rolled over on the runway. It was the third J-2 landing rollover accident in three months, which as I recall was almost half the fleet built to that time.

FAA ordered modification to the J-2’s nosegear, and that summer the company flew me out to the factory at Lake Havasu where I flew with Bill Evans in a modified J-2.

Bill Evans

I went to work for McCulloch Aircraft in 1969 and at the time the company was located in El Segundo,CA. At that time the J-2 was just undergoing it’s final FAA certification and later on the entire operation was moved to Lake Havasu City, AZ. I was there for two years until they moved back to Gardena,CA and it then became Aero Resources. During my time in LHC I was doing the Flight Training and later became an FAA designated pilot examiner for Gyroplanes. I also was doing Production Flight Test and Experimental flight test for the company. I stayed on with the company until 1974 when they finally closed their doors. This was at the Van Nuy, CA airport.

I think my total time in the J-2 was around 2200 hours. I flew the J-2 at the Paris Air Show and all over France. Also crossed the English Channel and did some flying in England as well. All and all it was a really fun aircraft to fly but had so many limitations when it came to performace. One of the biggest problems was the noise it produced. This really plagued the engineering department and nothing seemed to help. We had to wear special David Clark headsets and still the noise level in the cockpit was deafening. We did experiment with a 200 HP Lycoming engine and also a 3 bladed constant speed Hartzell prop. These improvement helped a little but in the end, it still did not have the desired performance. It had a very limited range with a lot of unuseable fuel left. The required distance for takeoffs was far more than acceptable. We were able to land in off airport locations but with the wood props it was usually an invitation to some major damage. The landing gear struts would some times remain extended or be uneven and this will make landing sometimes very exciting if you didn’t expect it.

We did develop several techniques that would enhance both the take and landing performance but was never able to get them certified.

In 1949 Helicopter Division of McCulloch Motors Corporation appointed as chief designer D. K. Jovanovich, formerly of Helicopter Engineering and Research Corporation, who developed his JOV-3 as the McCulloch MC-4 tandem rotor two-seat helicopter, first flown Los Angeles March 20,1951. Four-seat version developed as MC-4E. Later initiated quantity production of Jovanovich’s J-2 two-seat gyroplane, first flown in June 1962.

McCulloch Aircraft moved to California in 1946 and was renamed McCulloch Motors.

The McCandless M4 was a British single-seater ultra-light autogyro first flown in 1961. The original McCandless M4, developed by Rex and Cromie McCandless, was powered by a Triumph motor-cycle engine, this was later briefly replaced by a Norton motor-cycle engine which was abandoned in favour of a Volkswagen flat-four four-cylinder horizontally-opposed air-cooled engine which could be connected to the propeller without gears.

W. H. Ekin (Engineering) Company Ltd was formed at Crumlin, Co. Antrim, Northern Ireland, March 1969 to undertake production of six McCandless gyroplanes. The first one flew in February 1972. Extensive redesign was then undertaken and new prototype flew February 1973. Modified type called WHE Airbuggy.

There were two prototypes, one M1 and one M4 at the Ulster Folk and Transport Museum.

One flying VW engine-driven M4 type had the registration EI-ASR.

In total there were 8 built.

Cruising speed: 130km/h.