Since 1931 pilot and aeronautical constructor Pavel Grokhovsky began the development of means for landing troops. This new task received special support from the substitute of the People’s Commissar for Naval and Military Affairs and the chief of armaments of the RKKA, Mikhail Tukhachevsky.

After unsafe attempts to transport the paratroopers in underwing containers, Grokhovsky decided to try under his direction, Boris D. Urlapov designing a landing glider with a capacity for 16 paratroopers.

Urlapov had some experience working with gliders, for in 1925, in Saratov, he helped OK Antonov build the OKA-2 glider and later built a training model of his own design.

The task assigned by Grokhovsky envisioned the creation of a towed glider capable of carrying 1,700 kg of cargo or 17 paratroopers.

The glider was given the internal designation G-63 and was characterized by its unusual distribution of soldiers lying within the thick wing centerplane.

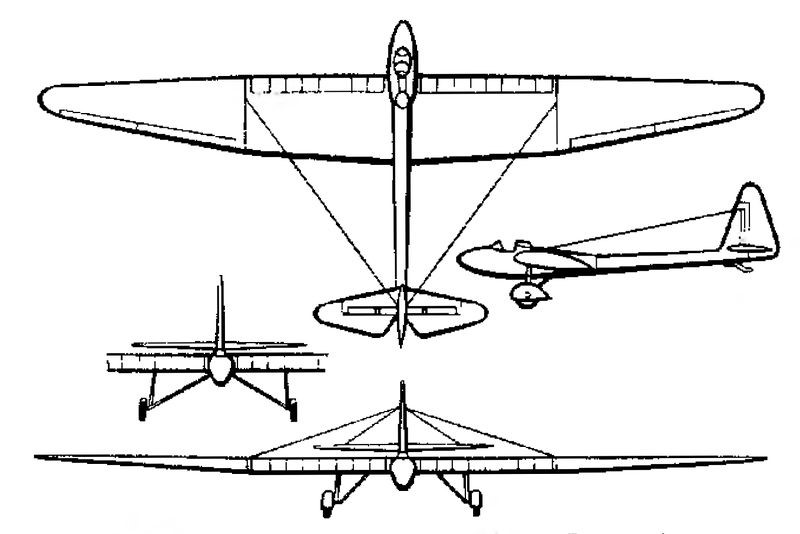

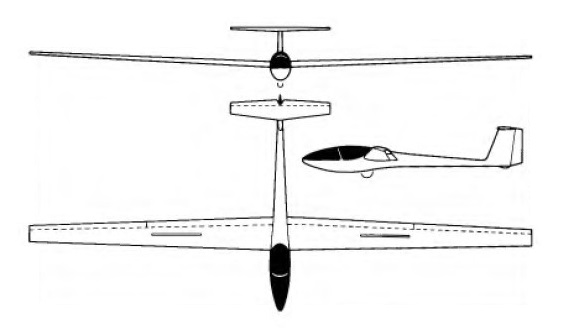

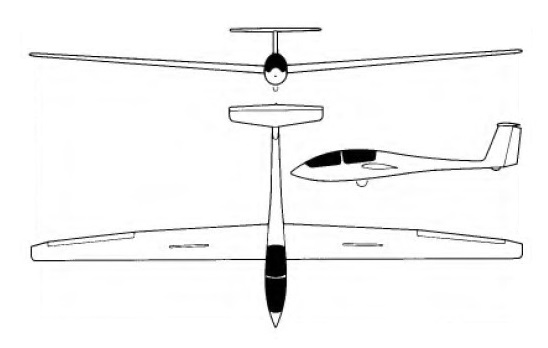

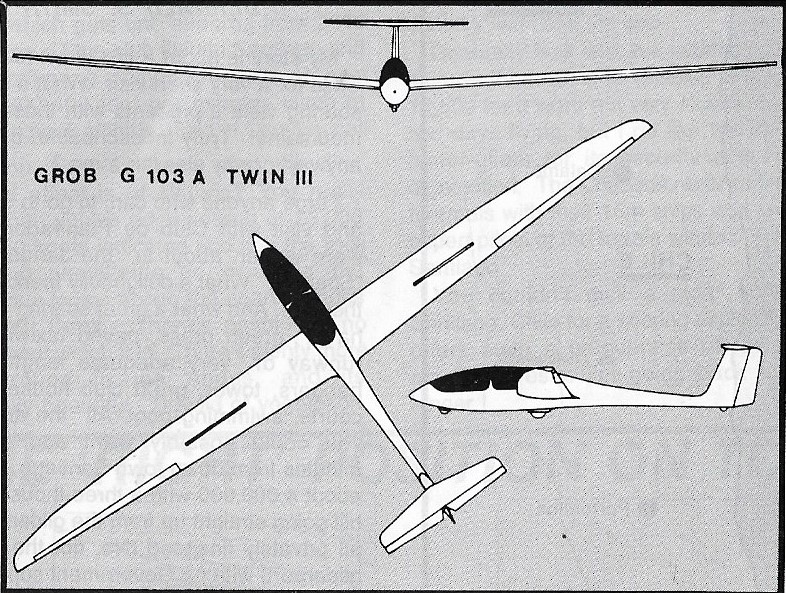

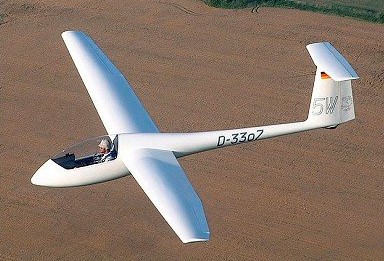

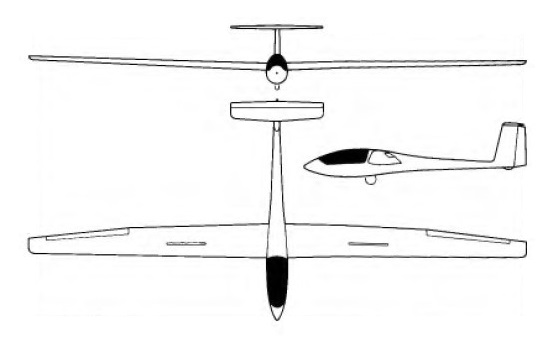

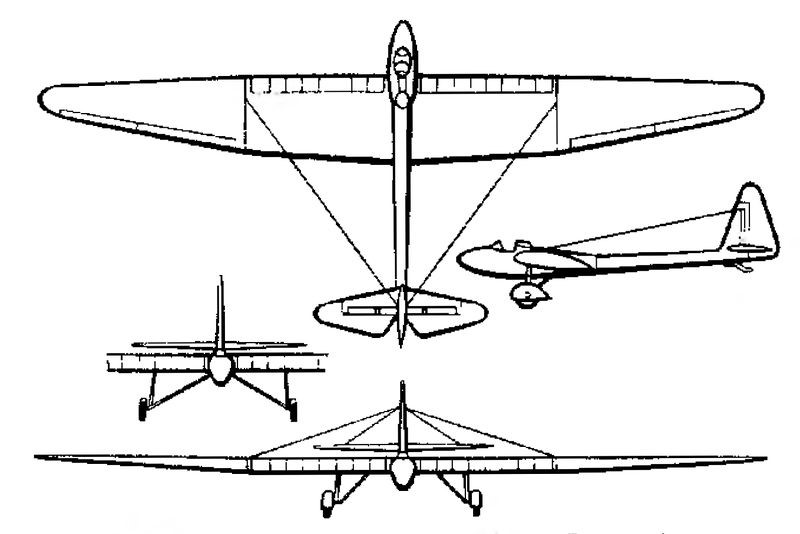

The G-63 glider was designed as a mid-cantilever wing monoplane with a wingspan of 28 metres. The front of the glider was designed as a projecting cockpit for the pilot.

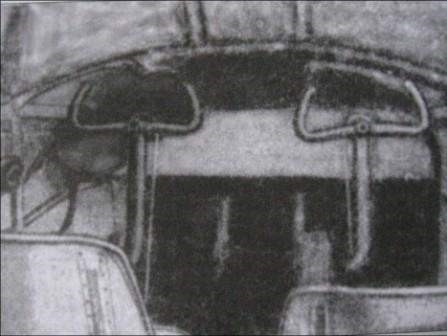

The thick wing featured a thick rectangular midplane with a large chord and trapezoidal wing consoles with rounded ends. This wing was built using profiles TsAGI-677, 678 and 679. The 16 soldiers were located prone in the midplane, in cells measuring 2100 x 660 x 550 mm separated by frames, which at the same time served as wing ribs. The leading edge of this centerplane was made up of a transparent cover that could be opened, pivoting upwards, for the loading and unloading operation of the soldiers.

All construction was made of wood. The fuselage had a monocoque structure with a plywood covering. Following the wing, the fuselage tapered to become a slim oval section tail bar, to which the tail unit was attached. Bracing cables to the wing were used to secure the tail cone.

The tail unit, of the monoplane type, featured stabilizers braced to the keel.

The original landing gear was designed with a conventional structure with a tail skid and was of the fixed type. The main landers, with large simple wheels, were fixed to the centerplane structure in the wing and by means of long studs to the fuselage frames in their lower region. In the G-31 version, the landing gears were reinforced and drop-shaped aerodynamic fairings were placed on the wheels.

The original version placed the pilot in an open cockpit with a windshield, located forward of the wing leading edge. The improved version G-31 included a double cabin with double control.

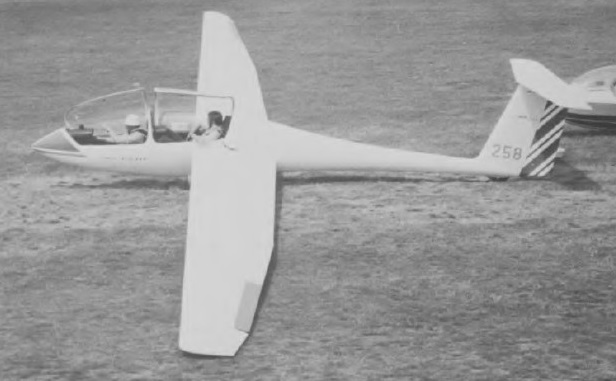

The G-63 (Russian: Гроховский Г-31 (Г-63)) glider was built in Leningrad Factory No.47. In October 1932 construction was finished and testing began. The first flights were made by Grokhovsky himself. Later the tests were continued with the participation of test pilot VA Stepanchonok. The towing was done with the help of a Polikarpov R-5.

In 1932, during one of the test flights, the G-63 crashed, receiving serious damage.

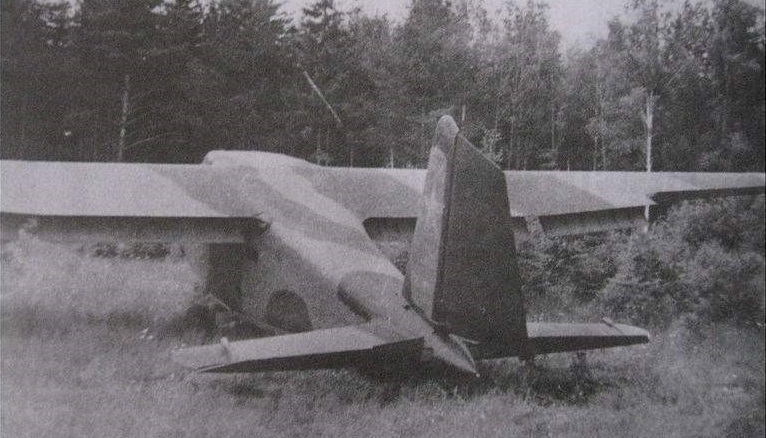

The glider repairs took until August 1933. During this time, construction changes were made, which included increasing the surface of the rudders, modifying the operating angles of the rudders and ailerons, adding a position for a second pilot, among others. The rebuilt glider received the new designation G-31.

A year later the construction of a second prototype was finished, which was named “Yakov Alksnis” after the head of the VVS. This example featured cut-out landing gear and reinforced landing gear. The rudder control cables were concealed within the tail cone structure.

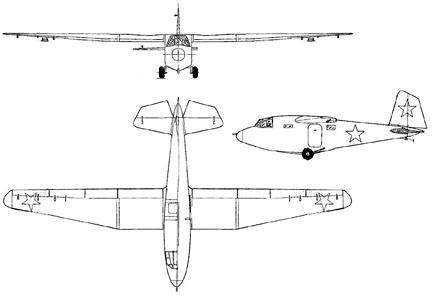

It was thought of giving the glider some capacity for autonomy. With this objective in 1935, the first G-31 prototype was equipped with a 100 hp M-11 engine, turning it into an experimental motorized glider or “planerlet” as it was called in the USSR at that time. The fuel capacity allowed the “planerlet” to stay in the air for about 20 hours.

During the tests, this example with a maximum load of 1,400 kg achieved a speed of 120 km/h with a cruise of 101 km/h and a ceiling of 5,000 m. Flights were made with a range of 2,000 km, but staying for 20 hours in a cramped compartment with hardly any movement capacity was extremely uncomfortable, especially considering that after landing the soldiers would have to go into combat.

With the aim of increasing speed, the installation of a more powerful engine was planned, which transformed the G-31 from a motor glider into a transport aircraft. This is how the G-31 version with the 700 hp Shvetsov M-25 engine would appear.

The little practical application of the idea and the lack of definition by the VVS of the technical specifications for a landing glider, resulted in its abandonment.

Despite the fact that in the early 1930s the USSR was at the forefront of landing glider development with the construction of the Grokhovsky G-31 and the Groshiev GNo.4, work in this direction did not receive enough attention and ended up being abandoned.

The Grokhovsky G-31 landing glider was unveiled to the public over Moscow Central Airfield in 1934 and according to historians was the origin in the development of the German DFS-230 landing glider.

Versions:

G-63 – Original version of the 1932 glider. It was damaged during testing.

G-31 – Improved 1933 model obtained as a result of the modifications introduced to the G-63 prototype after its accident.

G-31 “Yakov Alksnis” – Second example built in 1934 and named after the head of the VVS. It featured minor design improvements.

G-31A or MP – Modification of the first prototype with a 100 hp M-11 engine.

G-31/M-25 – Repowered version of the G-31MP with a 700 hp Shvetsov M-25 engine made in 1935 with the aim of improving performance.

G-63

Wingspan: 28 m

Wing area: 67.6 sq.m

Length: 12.37 m

Height: 3.3 m

Horizontal plane surface: 9.3 sq.m

Vertical plane surface: 3.6 sq.m

Aileron area: 8.1 sq.m

Wing aspect ratio: 11.6

Empty weight: 1290 kg

Wing loading: 44.4 kg/sq.m

Best glide ratio: 28.6

Crew: 1

G-31A

Powerplant: 1 × 700 hp M-25

Wingspan: 28.00 m

Wing area: 70.00 m²

Length: 18.60m

Empty equipped weight: 1400 kg

Maximum takeoff weight: 3200 kg

Wing loading: 46 kg/m²

Power load: 4.6 kg/hp

Payload: 16 equipped soldiers

Top speed: 135km/h

Crew: 2