Glider builder

HPH Ltd, Caslavska 126, P.O.Box 112, CZ-284 01 Kutn & Hor, Czech Republic.

HPH Ltd. took over the original molds and drawings for glider Glasflugel 304 from Mr. George Brauchle in 1998.

Glider builder

HPH Ltd, Caslavska 126, P.O.Box 112, CZ-284 01 Kutn & Hor, Czech Republic.

HPH Ltd. took over the original molds and drawings for glider Glasflugel 304 from Mr. George Brauchle in 1998.

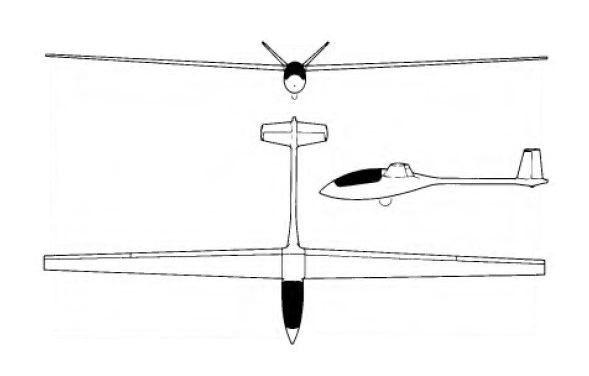

To meet the Standard Class specifications of OSTIV – the Organisation Scientifique et Technique Internationale du Vol a Voile – R.E. Schreder designed the 15m span RS-15 single-seater, which first flew in 1973 and is especially intended for simple and rapid assembly by homebuilders; it is licensed in the amateur-built Experimental category. No jigs are required, and most major components are prefabricated, thus reducing assembly time for a builder with no more than average mechanical aptitude to approximately 500 man-hours. The RS-15 is a pod-and-boom desgin which originally was intended to convert into various configurations, with wingspans of from 13 to 20 m. being matched with booms of suitable length, two-place pods, etc. In the event, Schreder decided to go with the basic 15 m. single-seat version featuring a fiberglass cockpit pod and a six-inch-diameter tube for the boom.

The cantilever shoulder wings are all-metal except for polyurethane foam plastic ribs spaced at 4in intervals. The main-wing spar caps are machined from aluminium plate and up to 200lb of water ballast is carried inside the wing box spars. Plain ailerons are featured, and these can be linked to the optional trailing edge flaps/air brakes, which are of aluminium sheet bonded to foam ribs.

The monocoque fuselage is built in two main parts: a prefabricated glassfibre forward pod, complete with bulkheads, floorboards and a moulded pilot’s seat, and a 6in diameter tail boom of aluminium tube with an all-metal V-tail which can be folded upwards for towing or storage.

The retractable monowheel has a hydraulic shockabsorber and brake, and there is a fixed steerable tailwheel, also with a shock-absorber.

A number of significantly modified RS-15s have been built including Otto Zauner’s One Yankee with his own design of fuselage and tailplane.

RS-15

Span: 15m / 49 ft 2.5 in

Length: 6.71 m / 22 ft 0 in

Height: 1.17 m / 3 ft 10 in

Wing area: 10.5 sq.m / 113 sq.ft

Aspect ratio: 21.4

Airfoil: Wortmann FX-67-K-150

Empty weight: 200 kg / 440 lb

Max weight: 426 kg / 940 lb

Water Ballast: 90 kg / 200 lb

Payload: 226 kg / 500 lb

Wing Load: 40.57 kg/sq.m / 8.3 lb/sq.ft

Max speed: 150 mph / 130 kt / 241 km/h (in smooth air)

Stall speed: 32.5 kt / 60 km/h

Max rough air speed: 104 kt / 193 km/h

Max aero-tow speed: 120 mph

Min sinking speed: 0.64 m/s / 2.1 fps / 1.24 kt at 43 kt / 80 km/h

L/DMax: 38 at 93 kph / 50 kt / 58 mph

Best glide ratio: 38:1

Seats: 1

No. Built: 20

The Tetra 15 is a carbon-fiber 15meter (with plans to have 18meter extensions) sailplane that Brad Hill and Bob Kuykendall built. It is registered as a homebuilt experimental glider, built by Brad Hill using the molds from the HP-24 project.

First flying in Jan 2012 in Arlington, Washington, the kit form is from HP Aircraft and called the HP-24. Bob Kuykendall started in April 2001 posting updates on the HP-24 project.

Brad accumulated roughly 400 hours in the Tetra 15 in two seasons.Performance is matched with other gliders where their factory claims 42:1.

This was the only kit-built composite glider being produced in the United States in 2014.

The HP-22 is- a high-performance, 15-meter class, side-by-side, two-place, self-launching, amphibious sailplane. It is designed for simple, rapid assembly by the homebuilder, licensed in the Amateur-built Experimental Category.

The basic layout so closely resembled an amphibian that making it watercapable added little extra weight or performance penalty. Every effort was made to produce a ship that could be built by the average amateur without any prefabricated parts, jigs or molds, the company says. Emergency wheels-up landings may be made on the keel skid.

The following design features and kit simplify construction of the HP-22 and reduce building time to approximately 400 man-hours: main wing spar caps cut from 1-inch thick aluminium plates; rectangular wing with all ribs the same size, fuselage panels and bulkheads that are glued together, which simplifies riveting and reduces caulking and leak and corrosion problems; epoxy bonding for rapid assembly of fuselage, wings and tall., automatic extension and retraction of engine, eliminating any need for manual or electric motor actuation; retractable wing floats and wheels to reduce drag and permit operations on water and snow: a complete kilit of materials with all complicated welding, machining, forming, panels and bulkheads, cable swaging, heat treating, etc. accomplished.

1984 Estimated prices: Tail Kit $350, Wing Kit $3,300, Engine Kit $3,000, Trailer Kit $2,500, Fuselage Kit $3,600, Complete Kit without Engine $7,000, Complete Kit with Engine $10,000, ‘ Drawings and Instructions Only $150:

The HP-19 features a straight tapered wing employing a Schreder modification of a Wortmann airfoil and tip winglets. Large flaps provide glidepath control.

Structure: metal, fiberglass, carbon fiber spar caps, foam ribs

Wing span: 15m / 49.2ft

Wing area: 10.5sq.m / 113sq.ft

Empty Weight: 213kg / 470lb

Payload: 227kg / 500lb

Gross Weight: 440kg / 970lb

Wing Load: 41.9kg/sq.m / 8.58lb/sq.ft

Water Ballast: 0

Aspect ratio: 21.4

Airfoil: Wortmann/ Schreder mod.

MinSink: 0.49 m/s / 1.6 fps / 0.95 kt

L/DMax: 42 80 kph / 43 kt / 50 mph

Seats: 1

No. Built: 1

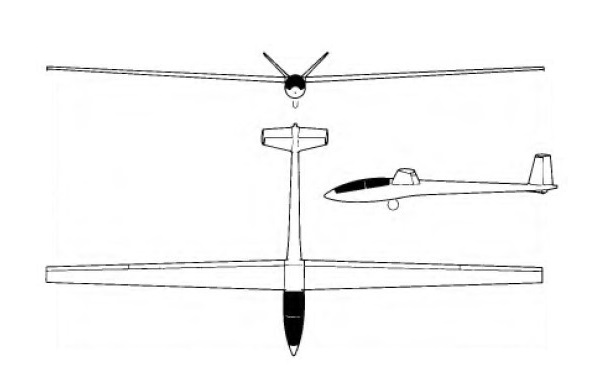

Designer Richard E. Shreder’s HP (for high-performance) 18 is a 15-meter Standard Class sailplane racer, which made its first flight in 1975; it is designed for sale in kit form for homebuilt construction and assembly, and about 170 had been built or were under construction by early 1979.

It is constructed with machined aluminium spars for the cantilever shoulder wing and precut hard foam wing ribs spaced at 10cm intervals; the HP-18A differs in having carbon-fibre spars but has similar wing rib construction. The HP-18 uses the Wortmann 67-150 airfoil. Camber-changing flaps and ailerons occupy the entire trailing edge deflecting 90 degrees, and up to 200lb of water ballast can be carried inside the wing box spar.

The design also incorporates certain improvements over the Standard Class RS-15 to which it is generally similar, such as new wing tips, a removable tailwheel, better gap seals and improved streamlining.

The HP-18 has a slightly longer fuselage than the RS-15 , with a circular instead of oval section, and this is supplied as a pre-formed Kevlar pod, aluminium rear fuselage and the V-tail; the pilot sits under a two-piece flush canopy. The control stick is side-mounted with attached brake handle and trim tab although modifications using a conventional stick have been made. A retractable Tost monowheel with a mechanically-expanding brake is supplemented by a steerable tailwheel.

One HP-18, C-GOIY, has been modified by its Canadian builders Don Band and Peter Masak to have winglets of glassfibre and balsa and Wortmann FX-60-126 section at the wing tips.

One belongs to the National Soaring Museum.

HP-18A

Span: 15m / 49 ft 2.5 in

Length: 7.16 m / 23 ft 6 in

Height: 1.22 m / 4 ft 0 in

Wing area: 10.66 sq.m / 114.7 sq ft

Aspect ratio: 21.4

Airfoil: Wortmann FX 67-150

Empty Weight: 213kg / 470lb

Gross Weight: 440kg / 970lb

Wing Load: 41.9kg/sq.m / 8.58lb/sq.ft

Water Ballast: 90kg / 200lb

Max speed (smooth air): 150 mph / 130 kt / 241 km/h

Top speed (rough air): 120 mph / 104 kt / 193 km/h

Max aero-tow speed: 120 mph

Stall clean: 40 mph

Stall flaps: 35 mph

Min sinking speed: 0.55 m/s / 1.8 fps / 1.07 kt at 45 mph / 39 kt / 73 km/h

Min. sink, 656 lb: 1.8 fps @ 50 mph

Best glide ratio: 40:1

Seats: 1

The HP-16 involved major changes in Schreder’s HP-15 design, with a different wing similar to the RS-15 of much lower aspect ratio and grater area. The aluminum wing skins are bonded to foam ribs, including rivet use and construction time. The HP-16 retains the very effective 90 degrees Schreder flaps. One belongs to the National Soaring Museum.

Structure: all-metal except for foam wing ribs.

Wing span: 15m / 49.2ft

Wing area: 10.5sq.m / 113sq.ft

Empty Weight: 192kg / 424lb

Payload: 226kg / 500lb

Gross Weight: 418kg / 924lb

Wing Load: 39.81kg/sq.m / 8.18lb/sq.ft

Water Ballast: 90kg / 200lb

Aspect ratio: 21.5

Airfoil: Wortmann 67-150

L/DMax: 36 89 kph / 48 kt / 55 mph

MinSink: 0.66 m/s / 2.16 fps / 1.28 kt

Seats: 1

No. Built: 20

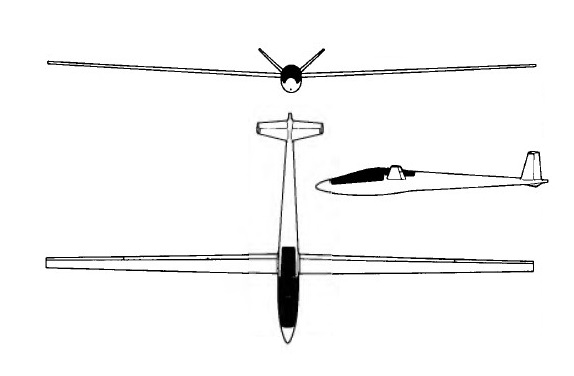

The 1970 World Championships were held at Marfa in Texas and Schreder designed the HP-15 for this contest to take full advantage of the high-lift Texan thermals; it was also intended to meet the new Standard Class rules which had come into force in 1969 allowing a retractable undercarriage and fixed-hinge flaps on 15m span sailplanes.

A high aspect ratio of 33 and the high wing loading of 7.99 lb/sq ft were chosen to ensure high speed performance, and the HP-15 was of all-metal construction. The two spar wings had only three ribs in each, plastic foam covered by rolled-to-contour metal skins and with plastic leading edges filling the intervening spaces; the ailerons droop in conjunction with the metal flaps. The fuselage is an aluminium monocoque and incorporates an aluminium butterfly tail with an included angle of 90°; this V-tail was a characteristic of previous Schreder designs. The retractable monowheel has hydraulic shock-absorber struts and the tailwheel is steerable.

Flight trials of the HP-15 – it first flew in the summer of 1969 – showed it to have difficult handling characteristics and it did not, in the end, fly in the 1970 World Championships nor did it go into production.

The wing was later retired and the fuselage re-winged.

Wing span: 15.0 m / 49 ft 2.5 in

Wing area: 6.97 sq.m / 72 sq.ft

Wing section: Schreder 69-180

Aspect ratio: 33

Length: 7.07 m / 23 ft 2.5 in

Empty Weight: 150 kg / 330 lb

Payload: 122 kg / 270 lb

Gross Weight: 272 kg / 600 lb

Wing Load: 39.02 kg/sq.m / 8 lb/sq.ft

Water Ballast: 0

Max speed: 150 mph / 130 kt / 241 km/h (in smooth air)

Stalling speed: 30 kt / 56 km/h

Max rough air speed: 98.5 kt / 183 km/h

Best glide ratio: 45:1 at 54.5 mph / 47.5 kt / 88 km/h

MinSink: 0.49 m/s / 1.6 fps / 0.95 kt at 45 mph / 39 kt / 72 km/h

No. Built: 1

Seats: 1

Structure: Metal

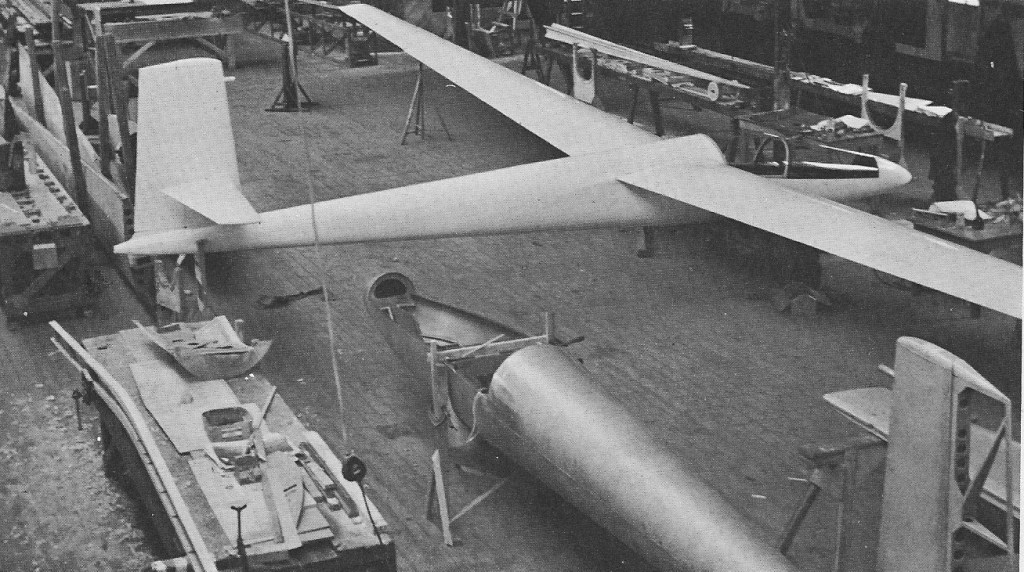

The all metal HP-14 was developed from the HP-13 which was essentially a HP-11 fuselage with the Wortmann airfoil used on the HP-12, with extended span. That wing was later mated to an improved fuselage to become the HP-14. The HP14 used lower wing loading and reduced aspect ratio in an attempt to maximize performance in weak conditions. All-metal construction rather than glassfibre was chosen because it involved considerably fewer man-hours for assembly than wood, and metal was easier and less critical to repair than glassfibre. The HP-14 features a folding V-tail and 90-degree flaps for glidepath control. The Bryan HP-14, of aluminium construction, made its first flight in prototype form on 24 June 1966 with a ‘butterfly’-type V-tail of 90° included angle, and this aircraft, flown by its designer Richard Schreder, won the 1966 US National Soaring Championships.

The Bryan HP-14 has an aluminium wing structure, with plain aluminium ailerons, and no spoilers are fitted. The fuselage is an aluminium monocoque, with a steel tube frame around the cockpit, and there is a manually retractable monowheel and a fixed steerable tailwheel; the monowheel has a hydraulic shock-absorber and brake. The pilot sits in a semi-reclining position under a long Plexiglas canopy consisting of two fixed pieces and a hinged section; a 90-channel transceiver and an oxygen system can be fitted.

More than 40 of all versions were built in the U.S. and by Slingsby in Great Britain. The ship has appeared with all three tail styles: the original had the Schreder V- tail, Slingsby produced the HP14C version with 18 m. wing and conventional tail, and the HP14T version used the C wing with a T-tail. The HP-14T version with a conventional T-tail first flew on 19 May 1968, and over 100 of both versions were built by Bryan Aircraft Inc and amateur constructors supplied by them with kits for the HP-14, which had all skins, ribs and bulkheads formed and welded parts welded ready for assembly.

The Slingsby HP-14Cs are ATC’d. Slingsby, to remain competitive, acquired a licence to build the American Bryan HP-14 all-metal high performance single-seater, designed by R. E. Schreder, while their own first all-metal design, the T53, was on the drawing board.

The first of two Slingsby-built HP-14s was completed and flown in May 1967, but the type was redesigned by Slingsby’s to suit British conditions and airworthiness requirements, the revised version being known as the HP-14C. The V-tail was replaced by a conventional fin and rudder with a fairly low-set all-moving tailplane, the wing span was increased to 18m (59ft 0.5in) and the cantilever shoulder wings moved back 6in to give a wider cg range and a roomier cockpit, the structure was redesigned to meet ARB requirements and a tail braking parachute was fitted. The original rack-and-pinion flap operating mechanism was replaced by a pneumatic system with two jacks to lower the flaps to 90°, when they serve as air brakes; on the US-built HP-14s the flaps could be hydraulically operated if the customer desired. The HP14C adopted a rechargeable pneumatic system to ease aerodynamic operating loads at high speed. The HP-14C prototype first flew on 11 April 1968 and the three HP-14Cs were built by Slingsby, two for the British team at the 1968 World Championships in Poland, and one for the Spanish team, but these were all that could be built before the firm’s main factory area was destroyed by fire on 18 November 1968.

Five more under construction were not completed due to loss of jigs in the fire, and were later stored, but six HP-14C kits were supplied to Australia and one to Finland, one more being built from a kit by W. J. Provins of Scarborough.

Another HP-14 built by Southdown Aero Services Ltd of Lasham had a V-tail of 50% greater span than the American version, and was later sold to the USA as N8838, where it was converted into an HP-14T with a T-tail.

The HP-14 was produced in kit form by Bryan Aircraft Inc of Bryan, Ohio.

As with many homebuilts, a number of builders have made design changes to their ships. In some cases these have been substantial. Andre Krutchkoff built his SHP-1 with his own design of fuselage with T-tail. Paul Bikle produced a modified HP14 (the T-6) with a 17.37 m./ 57 ft. span wing and control system modifications. Otto Zauner constructed an 18 m. model (called the Zauner OZ- 4) which has been modified substantially to have tip extensions with winglets to give a span of 19.2 m. / 63 ft, and a gross weight of 386 kg./ 850 lb.

HP-14

Wing span: 16.64m / 54.6ft

Wing area: 12.85sq.m / 138.3sq.ft

Empty Weight: 210kg / 464lb

Payload: 120kg / 264lb

Gross Weight: 330kg / 728lb

Wing Load: 25.68kg/sq.m / 5.26lb/sq.ft

Water Ballast: 0

Aspect ratio: 21.6

Airfoil: Wortmann FX 61-163

MinSink: 0.55 m/s / 1.8 fps / 1.07 kt

L/DMax: 39 89 kph / 48kt / 55 mph

Seats: 1

HP-14C

Span: 18.0 m / 59 ft 0.5 in

Length: 7.28 m / 23 ft 10.5 in

Height: 1.19 m / 3 ft 11 in

Wing area: 13.58 sq.m / 146.2 sqft

Wing section: Wortmann FX-61-163

Aspect ratio: 23.9

Empty weight: 290 kg / 639 lb

Max weight: 381 kg / 840 lb

Water ballast: None

Max wing loading: 28.1 kg/sq.m / 5.75 Ilb/sq.ft

Max speed: 135 mph / 117 kt / 217 km/h (in smooth air)

Stalling speed: 29.5 kt / 55 km/h

Max rough air speed: 104 kt / 193 km/h

Min sinking speed: 0.5 m/sec / 1.64 ft/sec at 52 mph / 45.5 kt / 84 km/h

Best glide ratio: 44:1 at 60 mph / 52 kt / 96 km/h

HP-14T

Wing span: 18m / 59ft

Wing area: 13.56sq.m / 146sq.ft

Empty Weight: 210kg / 464lb

Payload: 120kg / 264lb

Gross Weight: 330kg / 728lb

Wing Load: 25.68kg/sq.m / 5.26lb/sq.ft

Water Ballast: 0

Aspect ratio: 23.8

Airfoil: Wortmann Fx 61-163

MinSink: 0.52 m/s / 1.7 fps/ 1.01 kt

L/DMax: 41 89 kph/ 48 kt/ 55 mph

Seats: 1

Structure: all metal

The all metal HP-12A is a modification of the original HP-12 of R. E. Schreder, which was a one-of-a-kind built to fly in the 1965 World Championships at South Cerney, England.

The Standard Class HP-12 was derived from the HP-11. The HP-11, HP-11 A and HP-12 were built by Airmate at Toledo, Ohio-a company formed by Mr Schreder.

HP-12A

Wing span: 16.64m / 54.6ft

Wing area: 12.85sq.m / 138.3sq.ft

Empty Weight: 230kg / 525lb

Payload: 103kg / 230lb

Gross Weight: 343kg / 755lb

Wing Load: 26.69kg/sq.m / 5.45lb/sq.ft

Water Ballast: 0

Seats: 1

Airfoil: Wortmann FX 61-163

Aspect ratio: 21.6

L/DMax: 39 89 kph / 48 kt / 55 mph

MinSink: 0.55 m/s / 1.8 fps / 1.07 kt