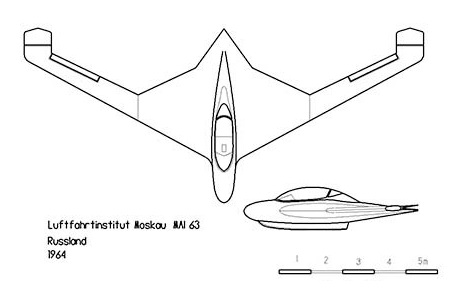

In 1970, following studies carried out by Alexei Ivanovich Pietsuj’s group in relation to tailless gliders, student VP Pushkin carried out a project of a new model with this configuration. It was a development of the concept outlined with the previous MAI-63. Named MAI-68 it was nicknamed “Pushinka” (Russian: МАИ-68 «Пушинка») in honour of its designer.

Professors GS Sadiekov, LA Matvieyev and VI Figurovski participated in the process of creating the new model. The general direction was in charge of AI Pitsuj.

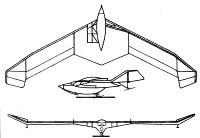

The glider was designed as a single-seater basic training device in order to be able to compare its performance to those of similar models with the classic scheme. It was decided to apply an integral construction in which the fuselage, wings and tail were fused into a single structure.

The construction was metallic with fabric covering. The structure of the glider was built with aluminum profiles.

The aircraft featured a fluted wing with variable thickness and variable line of lights along the wingspan as well as the long arm of the steering and rudders.

The selected wing profile was the R-Sh with a constant thickness of 15.5 throughout the wingspan. The force structure is composed of two spars of similar thickness between which the wing ribs were located. The wing leading edge was coated with 0.5 mm thick duralumin sheets.

The wing shape, in conjunction with the K-shaped structure of the short wing-end stabilizers, ensured the necessary longitudinal and lateral stability as well as good manoeuvrability. The location of the wing-end stabilizers had a positive influence on wing flow, significantly reducing the creation of vortices in this area.

Single-spar ailerons were attached to the wing structure at three points.

The alligator-type wing-end rudders ensured longitudinal control if operated integrally. When operating the pedals, these surfaces were opened independently, acting as aerodynamic brakes. By operating a single pedal, the resistance at this wing end allowed control of the rotation of the apparatus.

The control system was operated by cables.

The landing gear consisted of a main wheel with a front ski and stabilization straps on the wing.

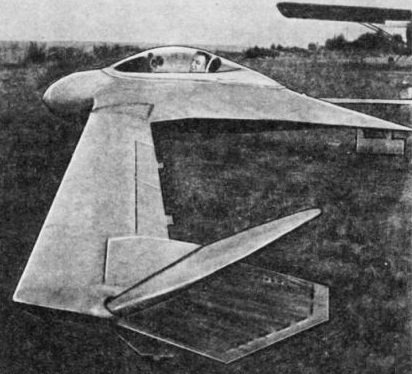

The cabin, for a single crew member, had a well-equipped instrument panel with an airspeed indicator, altimeter, artificial horizon and variometer. The transparent cover had an opening to the right. To improve downward visibility, the lower nose region and forward fuselage were coated with clear acrylic.

The MAI-68 experimental glider was built by V. Pushkin between 1968 and 1970. Ground tests began in July 1970, which were followed by flight tests at the MAI aeroclub aerodrome.

The test flights were developed by club director IG Yermakov. The “Hercules III” series tensioner was used for the launch.

During the ground tests it was possible to verify the effectiveness of the rudders, as well as the good stability and ease of control of the glider. The first short flights showed an acceptable longitudinal and transverse stability, as well as a marked delay in the reaction of the rudders. To eliminate this phenomenon, the opening surface of the elevator shafts was increased, achieving an increase in the effectiveness of these structures and allowing the development of the first flights at heights of 250 – 300 meters.

Tests of the glider at the MAI continued until 1972. In total they comprised 12 jumps at heights of 1 – 2 meters from the ground, 26 flights at 40 – 70 meters and four flights at 250 – 300 meters. A towed flight was made by a Yakovlev Yak-12.

The tests were continued at the TsAGI between 1973 and 1974. The flights, carried out by VN Vladimirov, were carried out at the Glider Station airfield. At this stage it was possible to measure the benefits and develop a series of mathematical models that verified the coincidence with the project calculations.

It was possible to establish a minimum glide speed of 45 km / h and an aerodynamic quality of 21. The effectiveness of the large lower surface of the center plane during takeoffs and landings was highly valued.

After testing the MAI-68, its designer VP Pushkin worked in the aeronautical industry and in this period he designed and built two other devices with this scheme, which showed excellent indicators and performance.

MAI-68 Pushinka

Wingspan: 10.00 m

Wing area: 10.2 m²

Aspect ratio: 8.54

Length: 5.00 m

Empty weight: 86 kg

Normal weight: 170 kg

Wing loading: 16.7 kg / m²

Minimum speed: 45 km / h

Maximum glide ratio: 21

Accommodation: 1