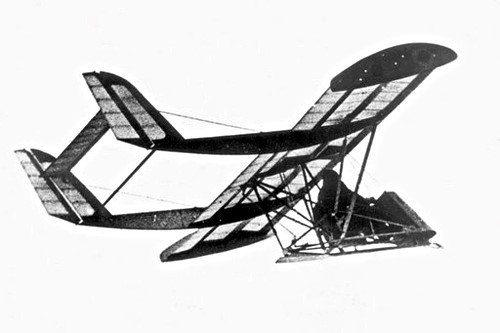

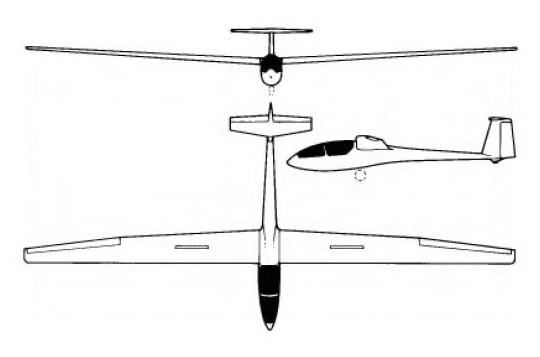

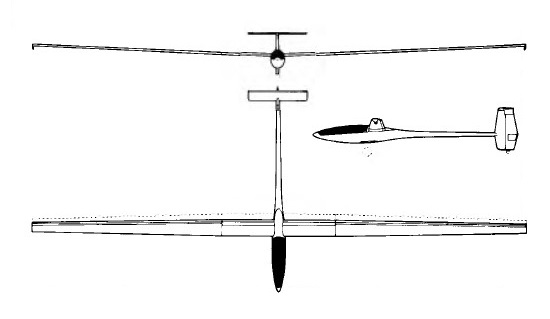

The BrO-21 Vyturys training glider prototype was built in Kuibyshev with the help of Aviation Factory engineers and Aviation Institute students.

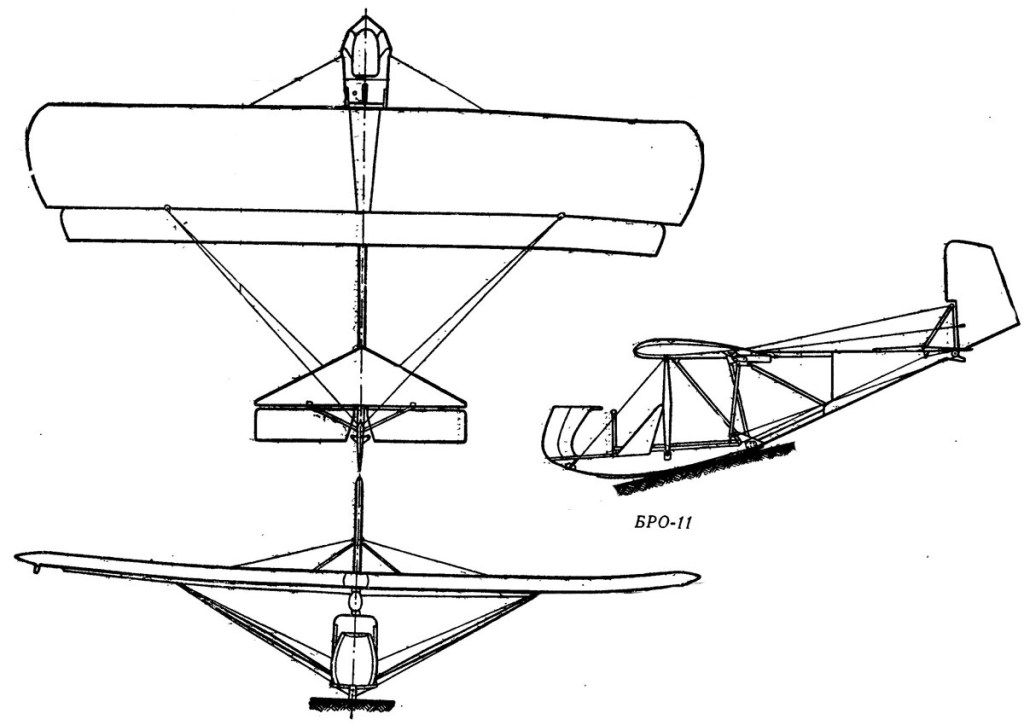

The wing of the of the BRO-21 Vyturys glider consists of four balances and two ailerons. The wings were arranged one after the other with an overlap of 70 mm, forming a 40 mm slit forming an angle of 7 degrees.

The BrO-21 1980 At the beginning of 1980, the construction of the second example of BRO-21 was started in Palanga, the construction of which was completed in Kaunas in 1980. June 20 his trials began.

Polymers and glass cloth were used in the construction. The gap between the spar is filled with epoxy- impregnated foam, covered with glass cloth.

The fuselage consists of a front part (cockpit) and a tail beam. The cabin is made of fiberglass. All cabin sides are covered with microporous rubber edging.

At the bottom, the cabin has 5 rubber “legs” to which it can be attached:

wide fiberglass ski (for winter),

ski with wheel 200 × 80 or 255 × 115 (for summer),

three-wheel chassis (training in landing)

a float that turns the apparatus into a hydraulic dispenser.

The tail beam is made of fiberglass.

The BRO-21 variant of the glider built in Kuibyshev, was demonstrated in Moscow at a union competition of youth gliding schools. The glider, starting with the shock absorber, showed a great advantage over another classic-designed training glider “Trener” developed by Kuibyshev.

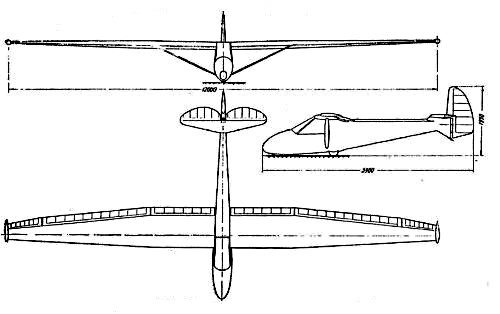

Wingspan: 5.2 m

Length: 7 m

Wing area: 10.5 m²

Empty weight: 84 kg

Take off weight: 160 kg

Pilot weight: up to 76 kg

Maximum speed: 100 km / h

Minimum speed: 35 km / h

Glide ratio: 12

Wing load: 15.2 kg / m²

Seats: 1