Designed by Wolf Lemske to Standard Class specifications, and built by Walter Schneider, the prototype was completed in March 1994, although the fuselage was first flown with LS6 wings in 1993.

Wolf Lemke had recommended further comparison flights with the LS6 and LS7 models, but under different conditions. He increased the angle of incidence between wing and fuselage for improved thermalling and good take-off handling. He used the unmodified LS6-c flapped wing and added winglets.

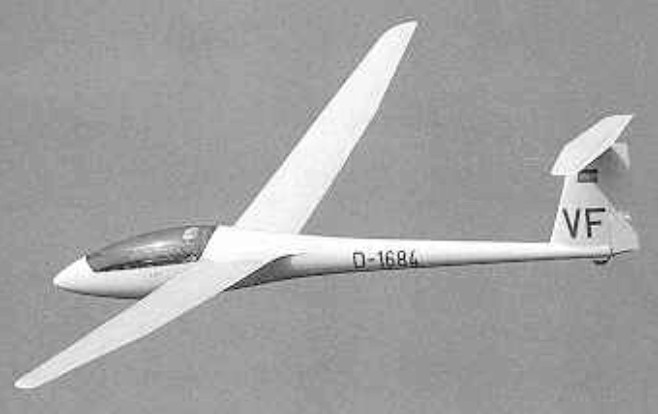

Winglets come as standard and a fin ballast tank is an option. Approach control is by top surface Schempp-Hirth airbrakes. Wingtip extensions bringing the span to 18 m are also an option.

From the beginning the fuselage was designed for the installation of an engine and even the installation of a total rescue system was initially considered. As LS8-b the airplane can be ordered also with engine preparation only, this facilitates retro-fitting of a sustainer engine considerably.

Typical for LS the wheel brake is heel operated via the rudder pedals; the manual however terms it emergency brake only due to rapid brake pad wear. The beefed up 575 kg version has a 5 in wheel replacing the 4 in one, thus improving ground handling on grass runways substantially. Retracting the undercarriage also brings the belly release up into the fuselage.

The instrument panel tilts up with the canopy and an emergency exit assistance is optionally available.

The design of the LS8-s with variable wing span caters for pilots, who prefer to fly standard class competitions and, in addition want the performance of 18 meters. It’s also easier to accommodate the glider in a tight hangar having only 14.20 meters span without Winglet. The LS8-a is also available as a ‘skinned down’ version with 15 m only.

The glider has the characteristically double tapered wing with Wortmann profile and kink in leading and trailing edge. Adding the 18-Meter-tips with the noticeably smaller winglets the pilot experiences yet another substantial improvement of flight performances. Thus the lift/drag ratio rises to 48 and minimum sink improves to 0,51 m/s. in addition, 190 liters of water can maximally be carried in the 4 wing tanks, such requires center of gravity correction with water in the fin tank. All control connections are made automatically; double flange airbrakes are installed in the upper carbon fiber sandwich surfaceThe engine installation of the LS8-st with a Solo 2350 weighs complete with Fuel approx. 50 kg, made up for by the all up weight increase to 575 kg.

The original pneumatic retraction mechanism proved expensive and unreliable; DG replaced it with the proven linear bearing actuator for their production version. Operation of the 15 KW engine kept deliberately simple with the DG proprietary control unit. Travel distance with sustainer is approx. 300 km.

After the acquisition of Rolladen Schneider by DG-Flugzeugbau in July 2003 production of the LS8 continued very successfully despite initial legal problems. The finish of the airplanes manufactured at DG is reportedly noticeably better. The LS8 will be available again as an “LS8-s” (and not as “DG-700” or similar). We will continue the 15m version as well as the 15/18m version and the Turbo with the newly developed engine actuation. Delivery is possible from summer 2004.

Variants:

LS8-a

Top performance with 15 m wing span

LS8-s

High Performance Sailplane with 15 or 18 m of wing span

By adding the 18 meter tips the Standard Class Glider LS8 becomes the LS8-s. Despite the bigger wing span the outstanding flying characteristics of the LS8-a stay the same but now with performance numbers which are comparable to the open class of the seventies.

Although there are no wing flaps the LS8-s has reached best possible results in 18 meter class competitions under weak but also at best possible weather conditions. Obviously the wing section (a derivative of the LS6, as it is well known) is still a match to the most actual airfoil designs. The combination of very easy handling qualities, of having no problems when encountering turbulent conditions, minimum performance loss because of dirty or wet wings means a well proven competition glider which is also suitable for club operations or flying just for the joy of it.

For the LS8-s an increase of the maximum take-off weight from 525 to 575 kg could be done for the 18m version in combination with the shock-absorbing retractable 5″main wheel.

LS8-t

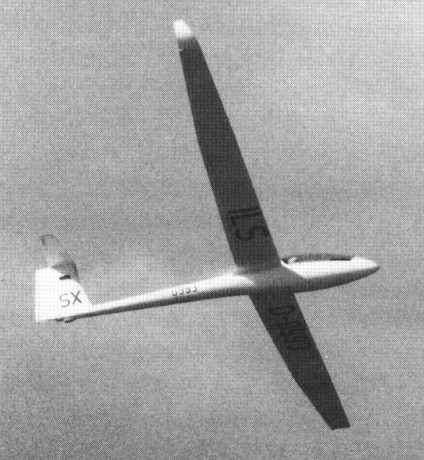

High Performance Sailplane with 15 or 18 meters of wing span and self-sustainer

As the popularity of the LS8-s began to increase more and more the question about a self-sustainer version was heard. Being able to get home on a weak day and travel by glider beyond the weather borders becomes reality with a self-sustainer engine. Furthermore the LS8-s with the increased wing span carries the additional weight of the engine installation better than a pure 15m sailplane. So we made the LS8-st with a self-sustainer, the LS8-s “turbo”.

The mold lines of the LS8-s were not changed – it was not even required to enlarge the fuselage.

The engine is the Solo 2350 two stroke two cylinder motor which is already well proven as a propulsion for sailplanes. The rigid two blade propeller is produced by Technoflug. With an additional weight of about 40 kg for the engine installation plus 10 kg of fuel there results a climb performance of 1 to 1.5 m/s and a range of 300 km or an endurance of 1 hour

The propulsion system was purposefully made as simple as possible. The engine plus propeller is very easy to install / uninstall.

If a customer should like to install the engine later, he can purchase a only motor-prepared version, too.

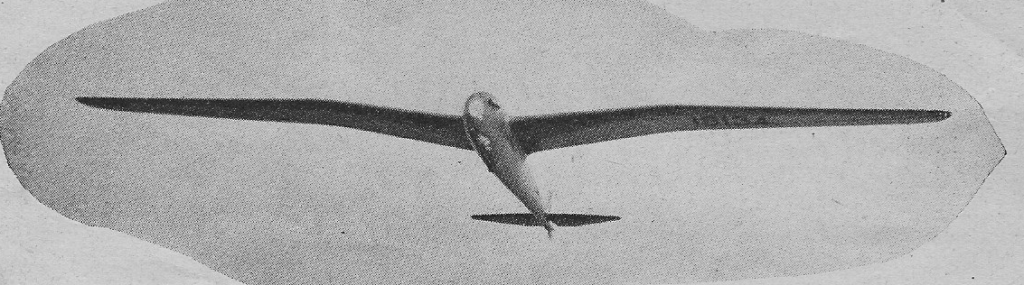

At the 1995 World Championships at Omarama, New Zealand, LS-8’s scored 2nd, 4th and 5th in the Standard Class.

LS8 Standard Equipment –

automatic control system connectors

retractable and sprung undercarriage

C.G. hook, retractable with landing gear

Nose tow hook

adjustable rudder pedals

wheel brake

Piggott-Hook

canopy with instruments panel hinged up front

infinitely adjustable trim system

oxygen flask receptacle

radio antenna in vertical tail fin

standard instrument panel

side pocket

double tapered wing in Carbon-sandwich-construction

15m winglets in Carbon-construction

ready to use water ballast system with funnel

ailerons in Carbon-construction

upper surface, double height air brakes

horizontal tail plane in Carbon-sandwich-construction

elevator in Carbon-Kevlar-construction

all control surface gaps sealed

backrest including headrest

temporary hinge at canopy rear for clean separation during emergency jettison

total energy connection in vertical fin

safety harness (multiple point buckle type)

registration signs

Cotton canopy cover

Optional Equipment

Tail dolly, covers for wings, leather upholstery, every instrument system offered, tail wheel 210x65mm, contest numbers, etc.

LS8 15m / 18m

Fuselage Length 6,72 m

Fuselage Width 0,61 m

Fuselage height 0,80 m

Wing Span 15,0 m / 18,0 m

Wing Area 10,5 m 11,4 m

Aspect Ratio 21,4 / 28,4

Min. Wing Loading about 32 kg/sq.m / ca. 30 kg/sq.m

Max. Wing Loading 50 kg/sq.m / 46 kg /sq.m

LS8-s /st: 50 kg/sq.m

Empty weight approx. 265 kg / 270 kg

Max. Take-off Weight 525 kg

LS8-s / st: 575 kg

Max. Cockpit Load 110 kg

Best Glide Ratio approx. 43 / 48

Minimum Sink Rate approx. 0,59 m/s / 0,51 m/s

Seats 1

LS8-st

Engine Solo 2350 ca. 18 hp

Fuel capacity 13 l

Climb rate in powered flight 1 -1,5 m/s