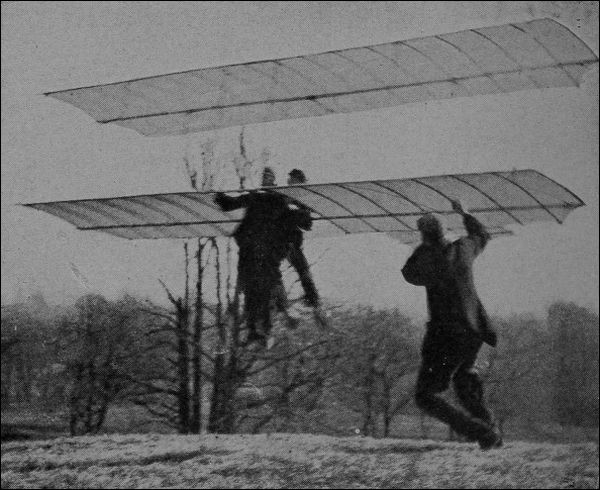

A glider of Lilienthal type but with a landing ski, built by Ingenieur Alois Wolfmüller from München, Germany, and datable to April 1908. It was a modification of a 1907 biplane glider, modified to monoplane configuration.

A glider of Lilienthal type but with a landing ski, built by Ingenieur Alois Wolfmüller from München, Germany, and datable to April 1908. It was a modification of a 1907 biplane glider, modified to monoplane configuration.

Triplane duo-seat glider designed and built in 1909 by Carl Wolf and August Becher, variously described as being from Oakland, California or Fitchberg, California. The aircraft is said to have made flights of up to 200 feet when launched from a specially built inclined ramp, 50 feet in height.

Wingspan: 19′ 8″

Wing area: 220 sq ft

As the head of the W.W.S. (Wojskowe Warsztaty Szybowcowe – Military Glider Workshops), Wacław Czerwiński designed the W.W.S. 1 Salamandra single-seat training glider during the mid-1930s. Built in Poland from 1936, the excellent handling properties, ideal for the solo training methods then in use, led to mass production in various workshops throughout Poland.

Construction of the Salamandra was entirely of wood with fabric covering on wings and tail unit. The fuselage consisted of a plywood covered nacelle for the single seat cockpit, with a wire-braced open strut rear fuselage supporting the cruciform style tail-unit. The high mounted wire braced wings were supported by struts from the bottom of the fuselage to approx 1/5 span. Wooden skids under the tail and fuselage nacelle comprised the undercarriage.

First flying in 1936, the most notable feat by a W.W.S. 1 Salamandra, in Poland, was an 11hr 15min flight by Buraka, between Brasław and Wilno, on 22 Aug 1938. Another marathon flight of 23 hours took place in Romania with a licence built version piloted by G. Braescu.

Before the war the WWS 1 was exported to Yugoslavia, Finland and Estonia.

During World War II, almost all Polish gliders and their technical documentation were destroyed or lost. After the war there was only one Salamandra left, kept hidden during the occupation, and it was decided to resume its production. Due to lack of blueprints, the design was reverse engineered in the IS (Instytut Szybownictwa – Gliding Institute). Five were built in March 1947 by the IS workshops as the first gliders in Poland after the war.

In 1948 a serial production resumed as IS-A Salamandra 48 in workshops in Jeżów. It was followed by improved variants Salamandra 49 and 53, produced also by other state-owned aviation factories throughout Poland, among others WSK Okęcie. After the war, 223 IS-A were built for Polish aero clubs, where they were used until 1962.

The later versions introduced airbrakes in the wings (Salamandra 49) and a windscreen (Salamandra 53). In Salamandra 53 there was introduced a bigger horizontal stabilizer, next retrofitted to earlier versions.

On 29 December 1956 there flew an export version Salamandra 53A – around 50 were exported to China, and a licence production started there. In China there was also developed a primary trainer two-seater variant, without a cockpit. In Yugoslavia there was built a similar glider Čavka, and in Finland – PIK-5. After migrating to Canada as a refugee, Czerwiński designed a modified Salamandra as the Czerwiński Sparrow, as well as an improved Sparrow designated Czerwiński Robin.

In 2017 one Salamandra was built in the Gliwice Aero Club, to original plans.

Variants:

W.W.S. 1 Salamandra

Production aircraft from 1936.

Wingspan: 12.48 m (40 ft 11 in)

Wing area: 16.9 m2 (182 ft2)

Wing profile: Göttingen-378

Aspect ratio: 9.2:1

Length: 6.48 m (21 ft 3 in)

Height: 2.3 m (7 ft 6 in)

Empty weight: 110 kg / 243 lb

Gross weight: 190 kg / 418 lb

Maximum speed: 150 km/h (93 mph)

Maximum glide ratio: 15.2:1 @ 56 km/h (30 kts / 35 mph)

Rate of sink: 0.81 m/s (159.5 ft/min)

IS-A Salamandra

Reconstructed postwar version from 1947

5 built (SP-320 – SP-324).

Empty weight: 140kg / 309lb

Gross weight: 225kg / 496lb

IS-A Salamandra 48

1948 version

775 built (first – SP-580)

IS-A Salamandra 49

1949 version

With strengthened construction, equipped with air brakes

93 built (first – SP-825)

IS-A Salamandra 53

1953 version

With enlarged horizontal stabilizer, windscreen and other improvements

50 built. (first – SP-1224)

IS-A Salamandra 53A

1956 export version for China

Around 50 built plus licence production.

In 1905, Charles, Paul and Walter Wittemann opened the first airplane manufacturing plant in the United States on their family estate in Staten Islad. After experimenting with gliders, they designed and built their first airplane in 1906.

In 1905, Charles, Paul and Walter (1896-1980) Wittemann opened the first airplane manufacturing plant in the United States on their family estate in Staten Islad. After experimenting with gliders, they designed and built their first airplane in 1906 and continued to manufacture a number of experimental planes and models until their ever-increasing production forced their move to a more spacious building on the north edge of the Newark meadows.

(Charles and Adolph) Wittemann Aeronautical Engineers

Ocean Terrace & Little Clove Rd

Staten Island NY.

USA

In 1907 the firm built a single-place, open cockpit biplane, powered by a 40hp Wright pusher. This featured a swivelling tailwheel, which was quite an advance in technology back then.

1907 also saw a single-place open cockpit triplane, powered by a 40hp Wright pusher.

Between 1908 and 1914 the firm built many planes, including Curtiss-type, single-place, open-cockpit biplanes, for notables of the time: Bud Mars, Ruth Law, Capt Thomas Baldwin, Lincoln Beachey, Cecil Peoli, Harold Blakesley, and others.

During 1911 the firm was involved in the construction of the Baldwin Red Devil III.

1916: Newark NJ. Aeronautical construction engineers of Newark, New Jersey. Rebuilt Airco D.H.4s to DH-4B standard for U.S. Army.

In 1917 they built a new plant at Teterboro Airport where the Wittemanns received the consent of the U.S. Army to convert unused DH-4 aircraft for the Post Office to be used for the first air mail postal service. The planes were modified to carry 400 lbs. of mail and in 1919 further improvements were made to accommodate 1000 lb. payloads. Approximately 75 of these single engine aircraft were produced at Teterboro.

c.1917: Wittemann-Lewis Aircraft Co Inc.

Had produced own-design mail carrier in 1920, when firm moved to Teterboro in 1919 (factory was eventually occupied by Fokker Corp). Contractors to US Post Office and USN for several aircraft.

During 1922-1923 built the Barling six-engined triplane bomber to Walter Barling’s design.

Built twin-engined Sundstedt-Hannevig seaplane 1923, for transatlantic attempt by Capt. Sundstedt.

During 1923, 25 de Havilland DH-4s were modified for mail carrying, powered by a 400hp Liberty 12. The last of the company’s efforts before filing bankruptcy.

In 1923 ended production to concentrate on engineering research. Of interest is that no Wittemann aircraft ever suffered a fatal or serious accident.

After bankruptcy in 1924, the firm property was acquired by Atlantic (Fokker).

Paul & Walter Wittemann were inducted in the Aviation Hall of Fame & Museum of New Jersey.

On 30 July 1904 steamship officer Stewart Winslow (1871-1961) tried to fly this self-built machine, in preparation for an effort to fly across Snake River at Lewiston, Idaho. According to reports the wing-equipped bicycle lifted off several times during a test run, before the front wheel failed because of a puncture. Winslow planned to build a wooden runway for the next try, but it never happened.

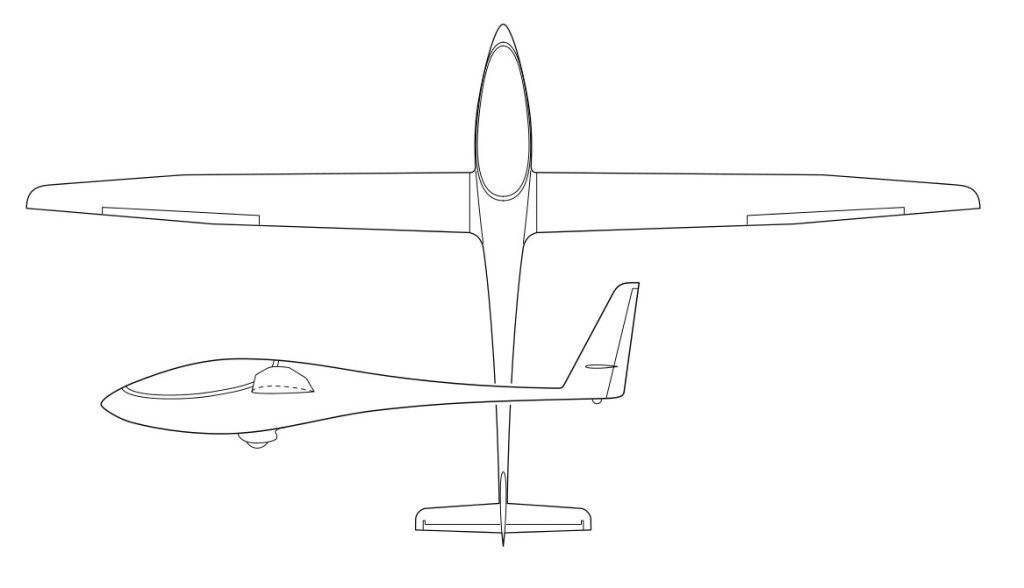

The Windward Performance Perlan 2 (English: Pearl) is an American mid-wing, two-seats-in-tandem, pressurized, experimental research glider that was designed by Greg Cole and built by Windward Performance for the Perlan Project.

The Perlan 2 is a follow-up design to the successful Perlan 1 and has as its design goal a flight exceeding 90,000 ft (27 km) in altitude. The aircraft will be used to study the northern polar vortex and its influence on global weather patterns. The program also hoped to beat the 85,069 ft altitude record set in 1975 by a SR-71.

The original funding for the Perlan Project was provided by Steve Fossett and he flew the Perlan 1, along with test pilot Einar Enevoldson to a glider altitude record of 50,761 ft (15 km) in the mountain waves of El Calafate, Argentina on 30 August 2006. Fossett was killed in a light aircraft crash a year later and the project floundered without funding. Since then, more than US$2.8M has been raised to build the Perlan 2, including a donation from Dennis Tito. In November 2013, a crowd-funding effort was undertaken. In August 2014 Airbus became a partner and major funder in the project.

The aircraft is made from composites. Its 83.83 ft (25.55 m) span wing has a high aspect ratio of 27:1 and is equipped with airbrakes. The pressurization system produces an 8.5 psi differential, and the two-person crew will not wear pressure suits. The landing gear is a non-retractable monowheel gear. Because the aircraft will operate at extreme altitudes, in only 3% of sea level atmospheric pressure, it will also be flying at true airspeeds in excess of 0.5 Mach. The aircraft was designed to minimize flutter and manage shock wave formation.

Perlan 2, benefitting from the lessons learned on Perlan 1’s ascent, incorporates a pressurized cabin to allow its pilots to enjoy unencumbered flight, with full control over stick and rudder, and many small switches. The cabin pressure of 8.5 pounds per square inch (psi) gives a cabin atmosphere equal to flight at about 14,000 feet. With an empty weight of 1,500 pounds, and a wing area of 262 square feet, the 84-foot span machine is amazingly light for the structural strength required for stratospheric flight.

With more wing area than a conventional sailplane, it would stay aloft, but never compete with such craft at lower altitudes. But in the thin air at 90,000 feet, with 98 percent of the earth’s atmosphere beneath it, it will be unrivalled. Because it carries two into a very hazardous realm, it is equipped with specialized equipment, including dual-redundant oxygen rebreathers, a drogue parachute to allow rapid descent in the unlikely emergency, and a ballistic chute for a lower-altitude emergency descent.

The aircraft first flew on 23 September 2015 at Redmond Municipal Airport, Oregon and started with flights in the U.S. Sierra Nevada mountain wave.

The record setting and research flights started in southern Argentina in 2016, by Einar Envoldson or Perrenod using rebreather oxygen systems. The aircraft was displayed at AirVenture in July 2015.

The first version of the Perlan reached 50,727 feet in 2006 with The Perlan Project’s founder Einar Enevoldson and lead project sponsor Steve Fossett at the controls setting a record.

The Airbus Perlan 2 reached new heights, flown by Jim Payne and Morgan Sandercock, breaking the world record for a glider flight as it soared to 52,172 feet on September 3 2017. An Aero Boero AB-180 tow plane pulled chief pilot Jim Payne and co-pilot Morgan Sandercock off the ground at Comandante Armando Tola International Airport, which sits at an elevation of 669 feet in El Calafate, Argentina.

The area around El Calafate is one of only a few places on Earth where mountain waves combine with a high altitude polar vortex; conditions critical to providing enough lift to bring a glider into the stratosphere.

Analyses by ground crews, which use data from weather balloons and meteorologists, did not indicate favorable conditions for a record flight. However, the pilots felt otherwise. They were right.

The glider was released at 10,500 feet and mountain waves carried the Perlan 2 to approximately 40,000 feet. There is generally a segment of altitude between the lifting layers where the glider can’t continue to gain altitude. An overlap is critical for bringing the glider into the stratosphere. And while the polar vortex did not quite overlap with the mountain waves, the glider was close enough that the pilots could redirect it to an area where they could continue to gain altitude.

The pilots said the climb rate was about 300 feet on average and the record flight lasted about 6.6 hours.

On 2 September 2018, Jim Payne and Tim Gardner reached an altitude of 76,124 ft (23,203 m), surpassing the 73,737 ft (22,475 m) attained by Jerry Hoyt on April 17, 1989 in a Lockheed U-2: the highest subsonic flight.

Perlan II

Wingspan: 83.83 ft (25.55 m)

Wing area: 263 sq ft (24.4 m2)

Aspect ratio: 27:1

Length: 33.33 ft (10.16 m)

Height: 7.25 ft (2.21 m)

Gross weight: 1,800 lb (816 kg)

Never exceed speed: 377 kn (434 mph, 698 km/h) true airspeed, 56kts indicated

Service ceiling: 90,000 ft (27,000 m)

g limits: +6/-4

Crew: two

The glider, called the Perlan (Norwegian for “pearl”), is modified from a Glaser-Dirks DG-505M manufactured by DG Flugzeugbau in 1995. Its original self-launching Rotax 535C engine was replaced with oxygen tanks, scientific equipment, and non-rechargeable “primary” batteries, oxygen regulators and flight instruments. Because of this, the Perlan had to be towed into the air for release, and since the cockpit was unpressurized, pilots had to wear NASA spacesuits to combat the extreme altitude which presented difficulties in permitting full control movements.

To reach 50,000 feet while keeping the crew safe, the Perlan 1 was equipped with:

High altitude radar transponder by Sandia Aerospace

Instrumentation and lighting to fly at night by Whelen Engineering

Data loggers to validate world record, LX-9000

Scientific instrumentation

Cameras to record meteorological conditions

Lithium-ion rechargeable batteries

Telemetry to communicate with mission control on the ground

On August 29, 2006, Steve Fossett and Einar Enevoldson flew the modified glider to a record-setting altitude of 50,727 feet (15,445 m) over the Patagonia region of Argentina. By capitalizing on stratospheric “mountain waves” and the Polar Vortex that forms around Antarctica each winter, Fossett and Enevoldson were able beat the previous glider altitude record by over 1,500 feet. (The record was subsequently broken by the Airbus Perlan II, which reached 52,172 feet on September 3, 2017.)

The Museum of Flight acquired the aircraft from the late Mr. Fossett’s Marathon Racing Company in 2009.

Wingspan: 59 ft

Wing Area: 179 sq ft

Aspect Ratio: 19.52

Length: 28ft

Height: 6ft

Empty Weight: 860 lb

Gross Weight: 1389 lb

Wing Loading: 7.8 lb/sq ft

Maximum Speed: 168 mph

Service Ceiling: 62 000.00ft

Crew: 2

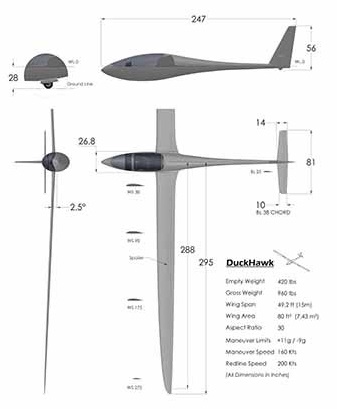

The DuckHawk is a development of the Windward Performance SparrowHawk and is intended as a higher performance glider than its predecessor, with very high structural limits and Vne. The DuckHawk has less than 10% parts commonality with the SparrowHawk. It features a cantilever wing, a single-seat enclosed cockpit under a bubble canopy and retractable monowheel gear.

Designed and produced by Windward Performance of Bend, Oregon, the aircraft is made from pre-impregnated carbon fiber. Its 15 m (49.2 ft) span wing employs a Greg Cole-designed airfoil, has an area of 80 sq ft (7.4 m2) and an aspect ratio of 30:1.

By December 2016 four examples had been registered in the United States with the Federal Aviation Administration, including three “V” models and one “E” model.

Since 2016 the aircraft has been no longer advertised as available by the manufacturer.

Variants:

DuckHawk E

Electric motorglider version, first example registered with the FAA in 2011.

DuckHawk V (Veloce)

Base model with an empty weight of 390 lb (180 kg), a maximum gross weight of 960 lb (440 kg) and load limits of +7/-5g. The first example was registered with the FAA in 2014 and three have been built.

DuckHawk SV (Super Veloce)

Proposed model with a 64% thicker spar, thicker fuselage, an empty weight of 435 lb (197 kg), a maximum gross weight of 960 lb (440 kg) and load limits of +11/-9g. None completed.

DuckHawk VNX

Proposed model with thicker wing skins, an empty weight of 455 lb (206 kg), a maximum gross weight of 1,150 lb (520 kg), maximum speed of 225 kn (417 km/h) and load limits of +11/-9g. None completed.

Specifications:

DuckHawk V

Wingspan: 49.2 ft (15.0 m)

Wing area: 80 sq ft (7.4 m2)

Aspect ratio: 30:1

Airfoil: Greg Cole-designed

Length: 20.6 ft (6.3 m)

Height: 3 ft 8 in (1.12 m)

Empty weight: 390 lb (177 kg)

Gross weight: 960 lb (435 kg)

Wing loading: 12 lb/sq ft (59 kg/m2)

Never exceed speed: 193 mph (311 km/h, 168 kn)

g limits: +7/-5g

Maximum glide ratio: 50:1

Crew: one

The SparrowHawk mid-wing, single-seat glider was designed to fit into the US FAR 103 Ultralight Vehicles category, including that category’s requirement that unpowered aircraft have a maximum empty weight of 155 lb (70 kg). The sailplane achieves this by utilizing a structure that is predominantly made from carbon-fiber-reinforced polymer.

The SparrowHawk’s multi-tapered, 36.1 ft (11.0 m) span wing employs five different airfoils and has an aspect ratio of 18.6:1. The wing features Schempp-Hirth style spoilers on the top surface. The cockpit can accommodate pilots who range in height from 63 to 75 in (160 to 191 cm). The landing gear is a fixed monowheel gear with an auxiliary tail wheel. The glider is finished with a two-part polyurethane paint. The aircraft can be launched by auto-tow, winch-launch, or aero-tow by both light aircraft and ultralight aircraft. Aerobatics are not recommended.

The SparrowHawk achieves a best glide ratio of 36:1 and a minimum sink rate of 119 ft/min (0.60 m/s).

Production ended after 35 were built. Since 2016 the aircraft has been no longer advertised as available by the manufacturer.

Wingspan: 36.1 ft (11.0 m)

Wing area: 70 sq ft (6.5 m2)

Aspect ratio: 18.6:1

Length: 20.6 ft (6.3 m)

Height: 4.5 ft (1.4 m)

Empty weight: 155 lb (70 kg)

Gross weight: 415 lb (188 kg)

Stall speed: 32 kn (37 mph, 59 km/h)

Never exceed speed: 123 kn (142 mph, 228 km/h)

g limits: +5.48/-4.0g

Maximum glide ratio: 36:1 at 50 kn (58 mph; 93 km/h)

Rate of sink: 119 ft/min (0.60 m/s) at 38 kn (44 mph; 70 km/h)

Wing loading: 5.93 lb/sq ft (29.0 kg/m2)

Crew: one