The Schweizer Aircraft Corporation was an American manufacturer of sailplanes, agricultural aircraft and helicopters located in Horseheads, New York. The company grew out of the Mercury Glider Club which produced the first two Schweizer gliders in the Schweizers’ barn. The company was originally called the Schweizer Metal Aircraft Company. Attorney Bob McDowell indicated to the Schweizers that they should move their manufacturing operation out of their father’s barn and relocate to the Elmira, New York area. The Schweizers received the suggestion positively as they needed more space to produce gliders, but they had no money with which to make the move.

It was incorporated in 1939 by three Schweizer brothers (Paul, William, and Ernest), who built their first glider in 1930.

McDowell convinced Elmira Industries Inc, the local business development corporation, to provide space for the Schweizers on the second floor of the Elmira Knitting Mill Building in return for stock in the company. This resulted in the Schweizer Metal Aircraft Company becoming the Schweizer Aircraft Corporation in 1939, with a sale of shares to Elmira Industries, local businessmen and soaring pilots.

Schweizer primarily produced light, piston-engined helicopters for use in utility and flight-training roles. The Schweizer 300CBi, originally designed and manufactured by Hughes aircraft as the Hughes 269 for the United States Army, is one of the most widely used training helicopters in the world. In 1986, Schweizer acquired all rights to the helicopter from McDonnell Douglas, who had purchased Hughes Helicopters in 1984. After Schweizer acquired the FAA Type Certificate, the helicopter was known for a short time as the Schweizer-Hughes 300C and then simply, the Schweizer 300C.

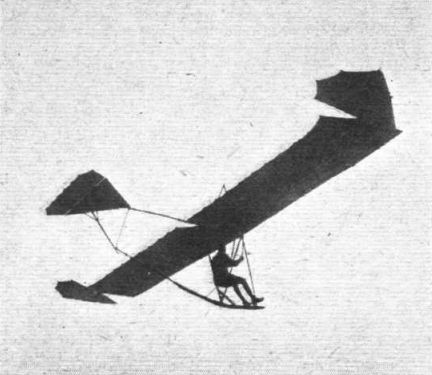

Schweizer is perhaps known best for its popular line of gliders (sailplanes), the earliest of which (the model SGP 1-1) was produced in 1930. Although very few of the early gliders were built, later models gained popularity, such as the SGS 2-8 and 2-12, which were adopted by the U.S. Army Air Corps for training as the TG-2 and TG-3, respectively.

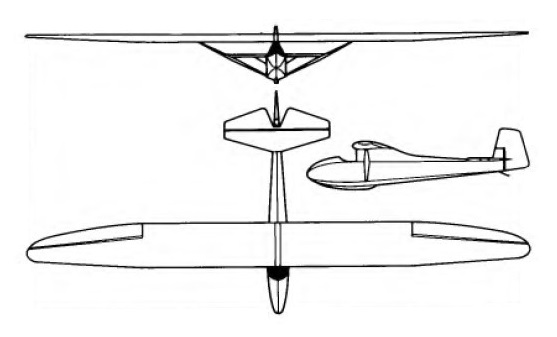

The Schweizer SGS 1-23 was a world class competition and record setting glider between its first flight in 1948 and the end of its production in 1967.

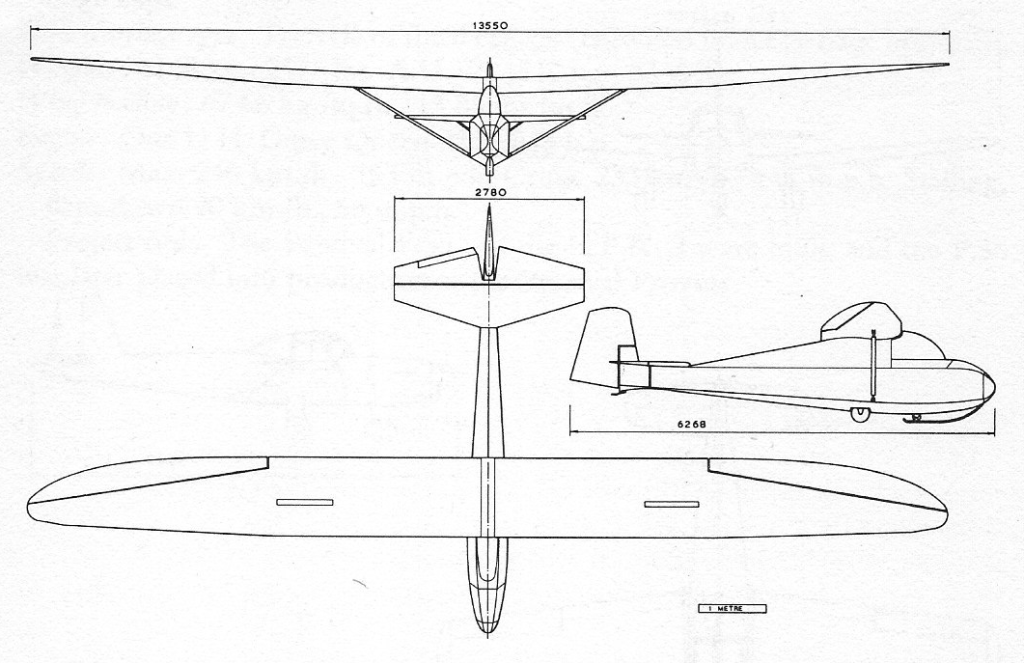

In the 1950s and 60s the Schweizer Aircraft Corporation designed and manufactured the very popular SGS 1-26 and SGS 2-33 gliders. They are easy to fly, with simple construction, and are quite rugged and forgiving. A powered light aircraft, the Schweizer SA 1-30 was tested, but did not go into production.

The 2-33 was adopted by the United States Air Force Academy as the TG-4, for use in introductory airmanship training. The Academy used over a dozen such gliders until 2002 when they were replaced by more modern sailplanes. The Royal Canadian Air Cadets continue to operate a fleet of over seventy 2-33As.

Other popular Schweizer gliders include the single-seat SGS 1-26 and the two or three-seat 2-32, both of which can be found in many soaring clubs and in private ownership across the United States.

Primarily designers and makers of sailplanes, one of which (SGS 2-32) fitted with piston engine was tested by Lockheed Aircraft Corporation as Q-Star for ‘quiet reconnaissance’ in Vietnam. On Q-Star was based the Lockheed YO-3A, using Schweizer wings and tail, new fuselage and muffled engine.

Company also built for Grumman the Ag-Cat agricultural biplane, later for Gulfstream, before acquiring the rights in 1981 (Ag-Cat subsequently produced by Ag-Cat Corporation).

Schweizer produced the Grumman G-164 Ag Cat, a single-engine biplane agricultural aircraft originally developed by Grumman in the 1950s. Under the contract with Grumman the airplane was built almost continuously between 1957 and 1981. During this period of time Schweizer built 2,455 of the airplanes.

In 1981 Schweizer bought the rights to the design and continued production under the name Schweizer Ag Cat. In 1995 Schweizer sold the rights to the Ag Cat to Ag-Cat Corp. of Malden, Texas. In February 2001 the design was sold to Allied Ag-Cat Productions Inc. of Walnut Ridge, Arkansas. Allied Ag-Cat is not producing new aircraft although a related company operates a large fleet of Ag-Cats.

The basic airframe incorporates many safety innovations, including a pressurized cockpit to keep pesticides out, air conditioning and a fuselage structure that is designed to progressively collapse in the event of a collision.

The basic designof Schweizer S269C remained unchanged over the years. Between Hughes and Schweizer, nearly 3,000 copies of the Model 269/300 have been built and flown over the last 50 years. Schweizer continued to develop the Model 300 by adding a turbine and redesigning the body to create the Schweizer 330, and then further developments led to the development of the Schweizer 333.

An improved version in the series, the Sikorsky S-434, was released in 2008.

In 1972 Schweizer hired David Thurston and production of his Thurston Teal was part of the agreement to work at Schweizer. The company produced three Schweizer TSC-1A1 Teals and nine TSC-1A2 Teal IIs before production was moved to Teal Aircraft in 1976.

The development of the Schweizer SGM 2-37 two-place motor glider for the United States Air Force Academy in 1982 led to a new area of expertise for the company. In the mid-1960s Lockheed had used the Schweizer SGS 2-32 sailplane as the basis for its YO-3 quiet reconnaissance aircraft. Schweizer decided to develop the SGM 2-37 into a similar concept aircraft as the YO-3. The result was the SA 2-37A and B, known as the RG-8A in military use.

The RG-8A was later developed by the company into the twin piston-engined and twin-boom SA 2-38 Condor with the US military designation of RU-38A Twin Condor. This design was further refined into the turboprop-powered RU-38B Twin Condor. The RU-38 was still in production in 2008.

It is believed the US Drug Enforcement Administration purchased aircraft designated Shadowhawk from Schweizer. The aircraft had a poor operational history. They may be designated SA 38B.

Other projects

In partnership with Northrop Grumman (formerly Ryan Aeronautical), Schweizer is developing the MQ-8 Fire Scout helicopter UAV.

Schweizer is currently participating in development of Sikorsky’s X-2 Demonstrator, a prototype aircraft using co-axial rotor blades with a pusher propeller for extra forward thrust.

Makes fuselage assemblies for Piper Aircraft Corporation and structures for Bell Helicopters. Became license-holder for Hughes 300 helicopter in 1983, producing piston-engined three-seat Model 300C from 1984 to present day and developing new 3/4-seat Model 330 turboshaft-powered helicopter (first flown June 1988); also supports Hughes Model 269s.

In 1986 flew the SA 2-37A low-noise special-missions aircraft suited to surveillance and other roles, followed in May 1995 by a radical twin-boom SA 2-37A conversion known as SA 2-38A. Two joined the U.S. Coast Guard as RU-38A Twin Condors for covert patrol and surveillance (one by conversion, one built as new).

In December 1999, Schweizer Aircraft celebrated its 60th Anniversary, and had built more than 2,160 sailplanes. Schweizer was a major U.S. aerospace contractor and no longer manufactured gliders.

Helicopter products offered by the company as of February 2009 included the 300C, 300CBi, and 333.

Previously the oldest privately owned aircraft company in the United States, Schweizer was acquired by Sikorsky Aircraft Corporation of Stratford, Connecticut, in 2004, and became a diversified aerospace company.

In 2011 and 2012 Sikorsky Aircraft Corporation laid off all the workers and closed the plant.