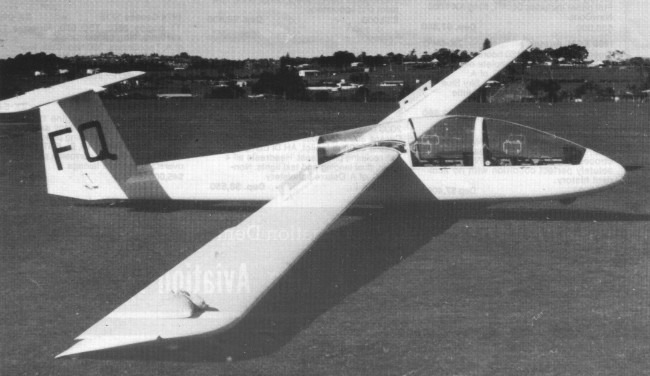

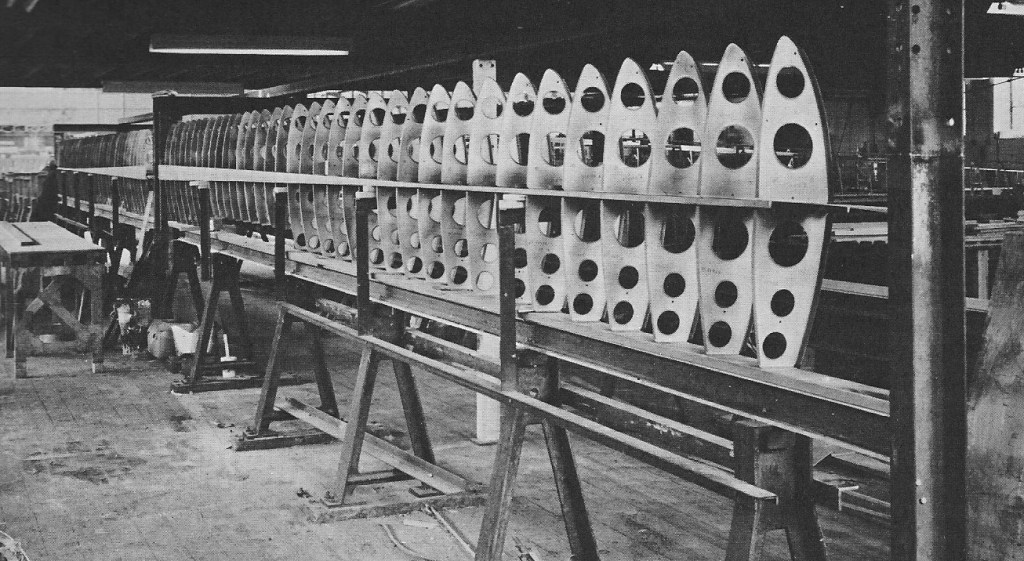

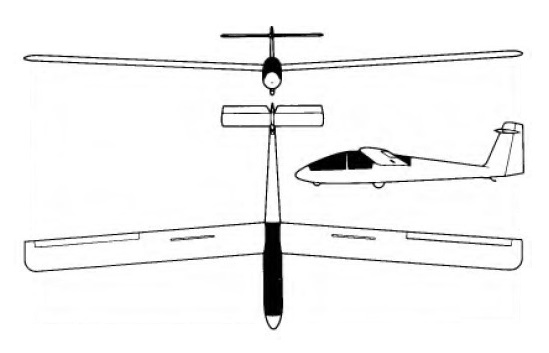

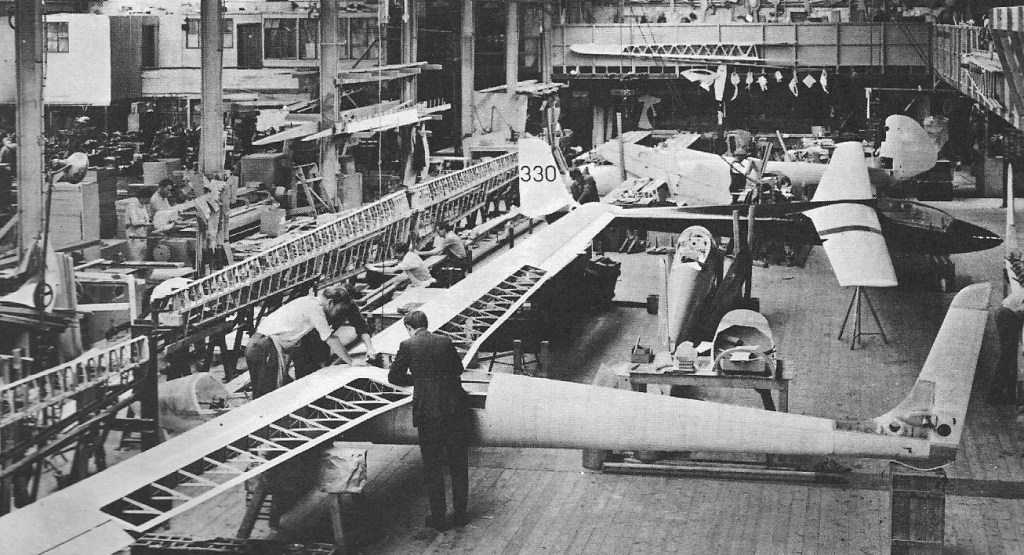

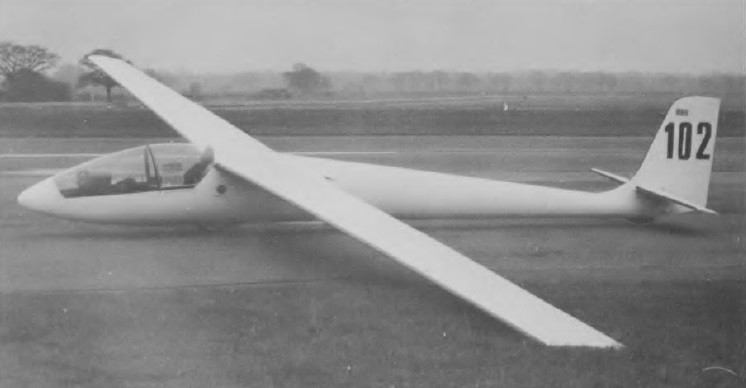

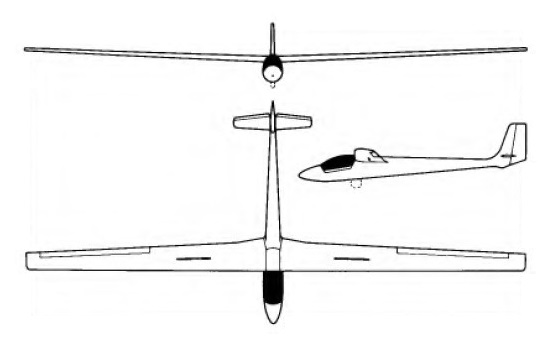

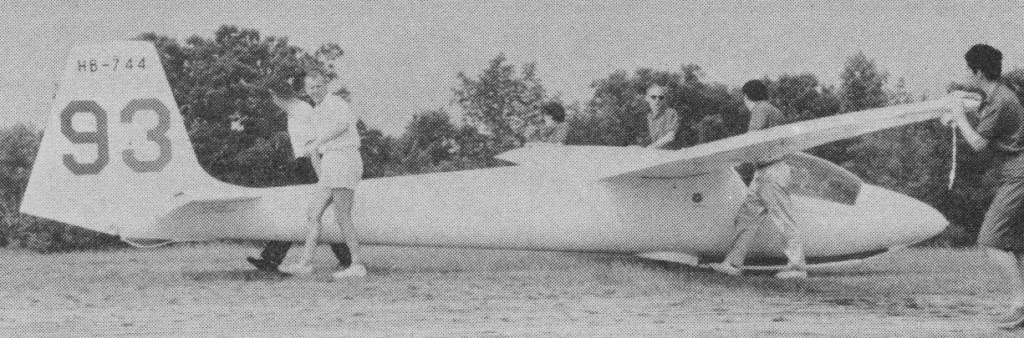

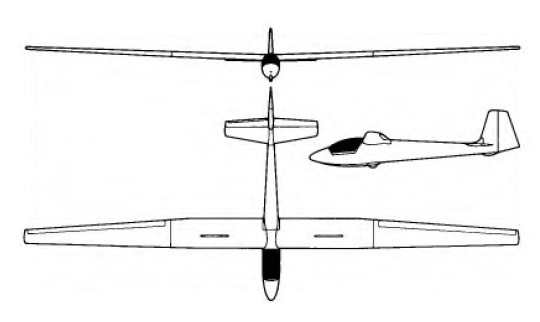

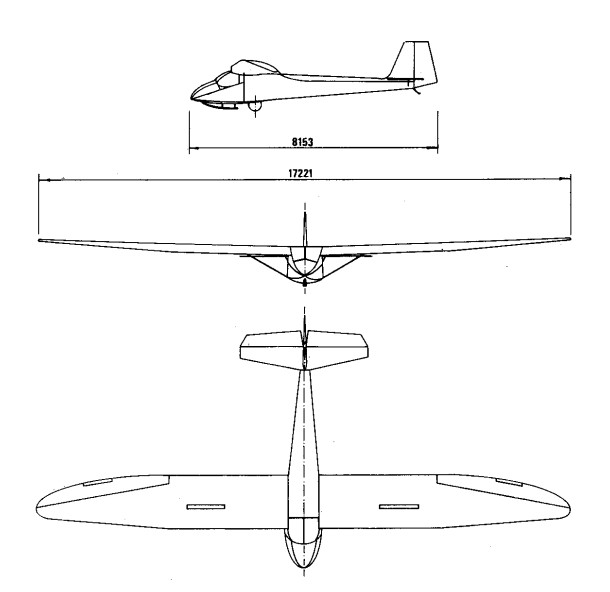

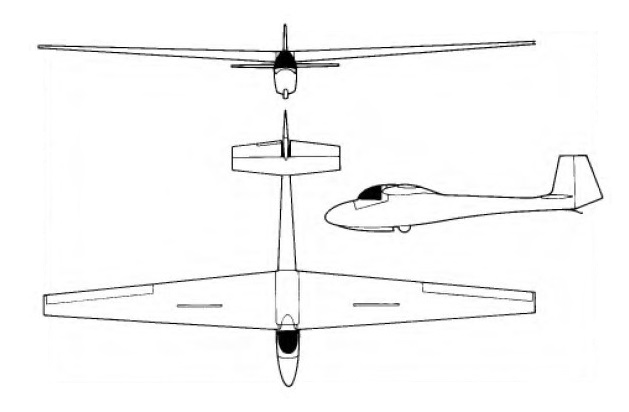

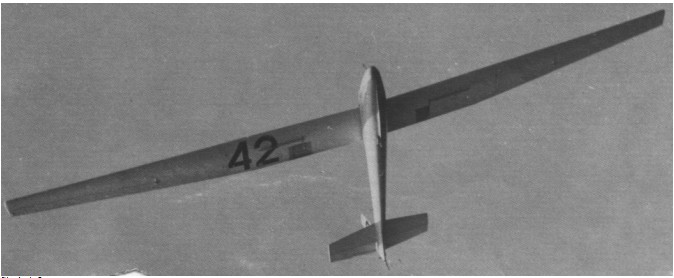

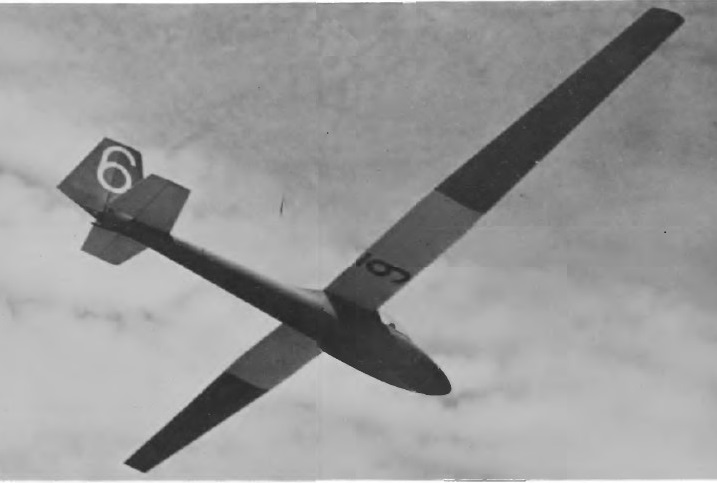

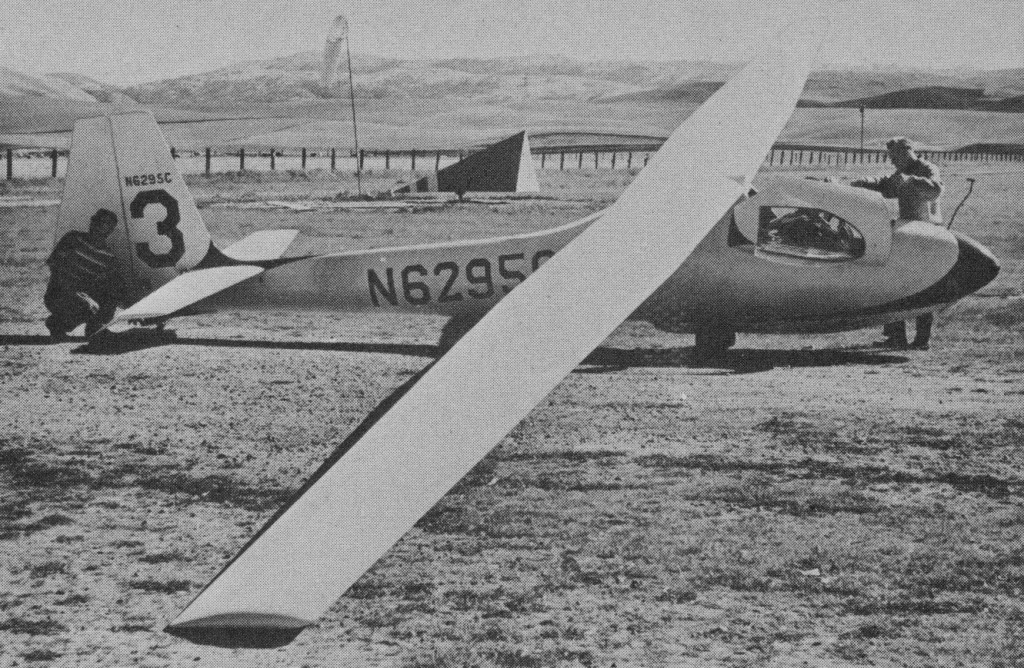

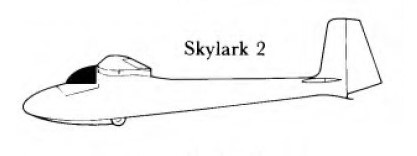

Designed by R. Sanders, the T-65 15m Contest Class single-seater is the first sailplane of entirely Slingsby design to appear since the liquidation of the former Slingsby Aircraft Co in July 1969 and its reorganisation as part of the Vickers group; it was later known as Slingsby Engineering Ltd (Aircraft Division). The Vega was designed to take advantage of the change in Standard Class rules permitting camber-changing flaps to be installed in this class after 1976. The all composite T. 65 was the first sailplane designed from the outset with a carbon fibre mainspar. The wings are of foam plastics sandwich construction with a single carbon-fibre main spar, which keeps the weight of each wing down to only about 130lb; the Wortmann wing section and carbon-fibre spar allow a constant 15% thickness/chord ratio from root to tip, giving performance benefits at the higher speeds. The wing tips are turned downwards to reduce tip stalling and are protected by inset metal rubbing strakes, and a convenient feature is that all controls are automatically coupled on rigging, leaving only the centre pin to be inserted. The wings also hold up to 195lb of water ballast in shaped plastic bags, thus avoiding any leakage which may occur when the wing itself is used as a tank. The cantilever mid-set wings are designed for optimum performance and have combined flaps/air brakes inboard and the ailerons outboard; the latter can be operated independently or in conjunction with the flaps. The wings have a unique single-lever operation for the flap and air brake system instead of using two separate levers as in other types; in the Vega the lever moves fore and aft in the usual way for air brake movement but is rotated by wrist action to select the flap positions which range from -12° to + 12°. The air brakes are hinged to the flaps with continuous flexible straps. Trim setting is adjustable by flap setting for hands-off flight at most operating speeds. Also automatic are the coupling of control and ballast-dumb plumbing on rigging.

The Vega prototype first flew on 3 June 1977 and, after some initial problems resulting from stiffness of the single-lever flap/air brake control, resumed test flights in November that year; the first production delivery was in April 1978, by which time 48 had already been ordered.

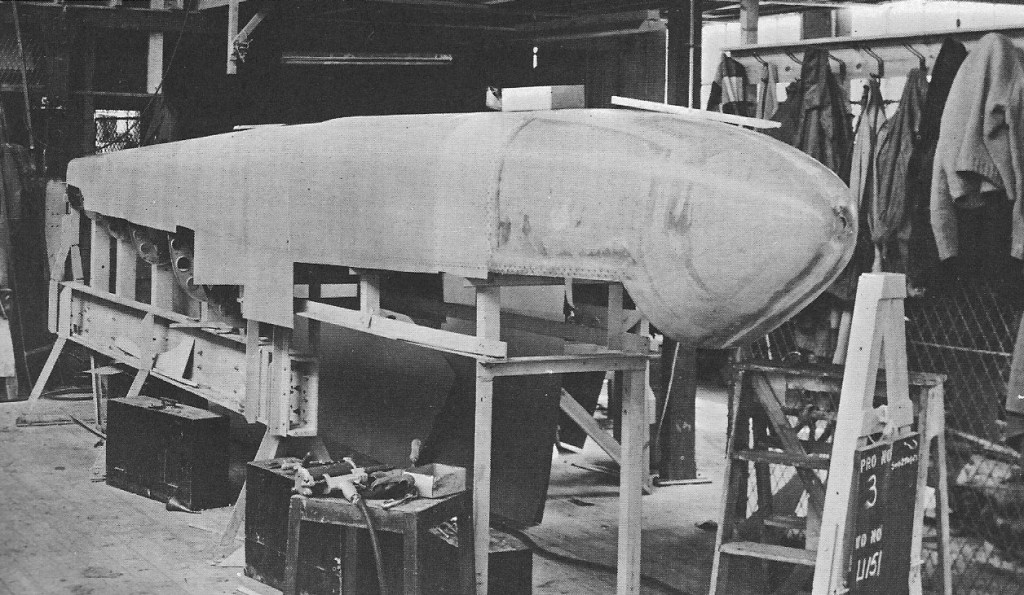

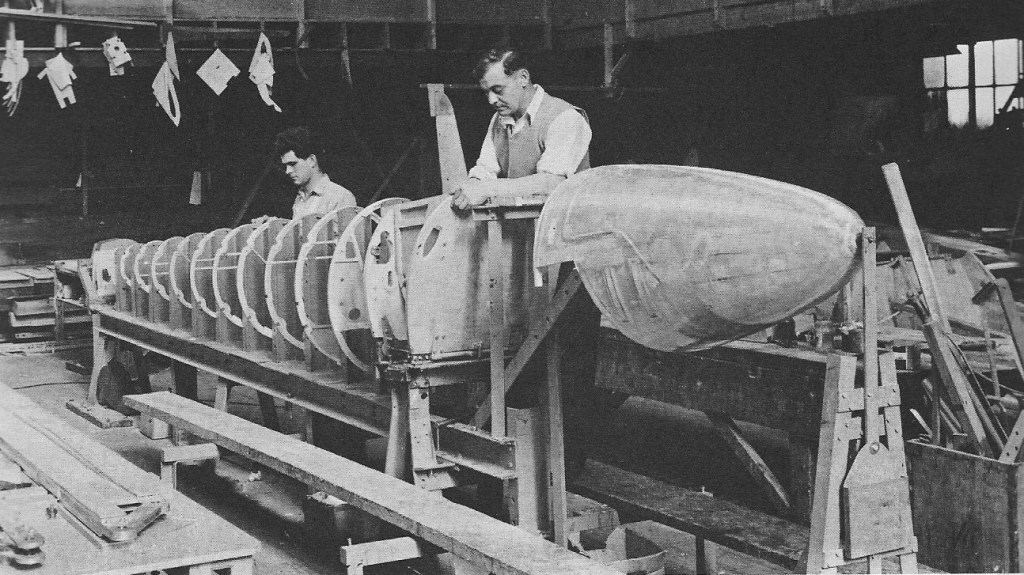

The fuselage is a conventional semi-monocoque plastics structure, and is gently ‘waisted’ to reduce the possibility of airflow separation over the wing/fuselage junction; the tow hook is carried on the frame that carries the monowheel, and retracts with it. The latter has a brake, and an unusual feature for a sailplane is that the Vega’s tailwheel retracts as well. The pilot sits upright under a long one-piece canopy which opens forwards and upwards, and is jettisonable. The cantilever T-tail has a tailplane of symmetrical Wortmann section with a carbon-fibre spar and a separate elevator with a spring trimmer.

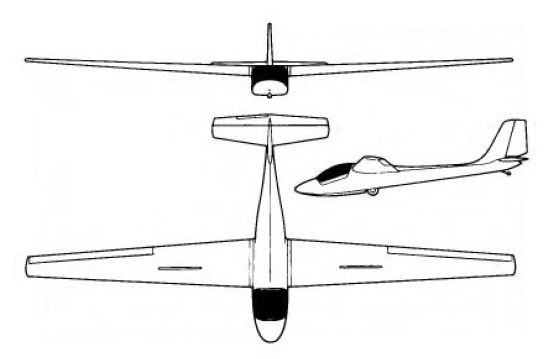

The A model has glass wing skins and 100 kg/ 220 lb of water ballast, while the D model has Kevlar skins for added strength and 160 kg./ 352 lb of ballast. The T. 65C model is a Sports Class variant. The T65C Sport Vega first flew on 18 December 1979, and this version differs from the Vega in having a glassfibre main spar, rotating trailing edge air brakes instead of flaps, and a fixed monowheel and tailwheel. There is no provision for water ballast. The T.65D was first built in 1979 with a standard price at the time of US$17,900. At the time it was produced, the Slingsby company operated under the name Vickers-Slingsby, but the Vickers part was subsequently dropped.

By the beginning of 1980 34 Vegas had been delivered.

Span: 49 ft 2.5 in

Length: 22 ft 0.5 in

Height: 4 ft 11 in

Wing area: 108.2 sqft

Aspect ratio: 22.4

Empty weight: 515 lb

Max weight: 970 lb

Max speed: 155 mph (in smooth air)

Max aero-tow speed: 92 mph

Min sinking speed: 2.21 ft/sec at 51 mph

Best glide ratio: 42:1 at 69 mph

T.65D

Wing span: 15m / 49.2ft

Wing area: 10.05sq.m / 108.2sq.ft

Length: 22 ft

Height: 4.75 ft

Empty Weight: 236kg / 520lb

Payload: 600lb / 272kg

Gross Weight: 1120lb /508kg

Wing Load: 10.35lb/sq.ft / 50.5kg/sq.m

Water Ballast: 352lb /160kg

Airfoil: Wortmann FX 67-K-150

Aspect ratio: 22

MinSink: 0.56 m/s / 1.85 fps / 1.10 kt

No. of Seats: 1

L/DMax: 42.1 @ 111 kph / 60 kt / 69 mph

Max speed: 135 kt

Stall speed: 34 kts

Rough air airspeed: 135 kts

No. Built: 80

Structure: carbon fibre main spar, Kevlar wing skin, fibreglass fuselage and tail

Vega

Wing span: 15.0 m / 49 ft 2 in

Length: 6.72 m / 22 ft 0.5 in

Wing area: 10.05 sq.m / 108.2 sq ft

Wing section: Wortmann FX-67-K-150/FX-71-L-150

Aspect ratio: 22.4

Empty weight: 234 kg / 516 lb

Max weight: 440 kg / 970 lb

Water ballast: 88 kg / 195 lb

Max wing loading: 43.8 kg/sq.m / 8.97 lb/sq ft

Max speed: 135 kt / 250 km/h

Stalling speed: 36 kt / 67 km/h

Min sinking speed: 0.67m/sec / 2.21 ft/sec at 44 kt / 82 km/h

Best glide ratio: 42 at 60 kt / 111 km/h