1929: St Louis Aircraft Co

8000 N Broadway

St Louis

MO

USA

The St. Louis Aircraft Corporation was incorporated as a subsidiary of the St. Louis Car Co. during the First World War, in response to the Army’s urgent need for large quantities of aircraft to support the training of military aviators needed to meet American commitments to the Allies. But St. Louis Car (a highly successful manufacturer of railway cars and streetcars) had already been actively exposed to the new world of aviation. In late 1915, Tom Benoist, St. Louis’ earliest aeronautical entrepreneur, had arranged to construct his large Type 15 twin engine, six-seat flying boat in the St. Louis Car shops, lacking sufficient room in his own facilities. Sensing an opportunity to sell flying boats to Allied combatants in the War, Benoist contracted with St. Louis Car in October, 1915 for the production of large numbers (lots of 1000) of similar flying boats. However, Benoist’s sales efforts in Europe were eclipsed by those of Glenn Curtiss, and consequently no flying boat production occurred at St. Louis Car.

Later, when the U.S. did enter the War, Edwin B Messner of the St. Louis Car joined with AJ Seigels’ Huttig Sash and Door Co. (also of St. Louis) to form the St. Louis Aircraft Corporation, which went on to manufacture 450 JN-4D Jenny trainers (a Curtiss design) for the U.S. Army. The company became one of six across the country to produce the Curtiss JN 4D Jenny with first deliveries in 1918. The first order was for 200 planes, the company delivered 30 aircraft per month, and 57 JN 4D October 1918.

Although St. Louis Aircraft continued to exist (as a wholly-owned subsidiary of St. Louis Car) after World War I, its hopes of producing aircraft for private use were stymied by the glut of surplus military aircraft that became available. The company remained dormant until the so-called “Lindbergh Boom” in aviation developed in the wake of Lindbergh’s heroic solo flight from New York to Paris in May, 1927. An ingredient of this surge in aviation activity was the advent of powerful, reliable, air-cooled radial powerplants to replace the bulkier W.W. I-vintage water-cooled OX-5 and Liberty engines. St. Louis Aircraft seized the opportunity afforded by the “Lindbergh Boom” in 1928 to produce a line of light, enclosed-cabin, two-seat, single radial-engine monoplanes christened Cardinals. At 1929 Detroit Aircraft Show exhibited the Cardinal high-wing monoplane, the company’s first airplane. Cardinal Senior which followed had more power.

Unfortunately, the Cardinal’s timing was not ideal: having been beaten into production by such highly successful similar private aircraft as the Monocoupe, Curtiss Robin, and others, the Cardinal did not sell well, becoming an early victim of the Depression-era aeronautical slump. The last of 21 Cardinals was delivered in 1931.

The company had ordered 100 100 hp Kinner radial engines to power the KT monoplane light, but production ceased in 1931 at the height of the depression.

Having survived for several years on development and production contracts for military aircraft parts and equipment, St. Louis Aircraft didn’t produce another airplane until it brought out a biplane primary trainer in 1935, hoping to win an Army production contract. Initially unsuccessful, St. Louis Aircraft continued to develop the airplane and demonstrate it (including a crash at Wright Field in 1936) for the Army, which eventually acquired a trial batch of 14 trainers in 1939. The Army identified these trainers as PT-15. The hoped-for big production orders were not forthcoming, however, being won instead by the now-famous Boeing/Stearman PT-13/PT-17/N2S Army/Navy primary trainer.

While continuing to manufacture crew cars for motorized Army observation balloons (many of which operated at nearby Scott Field), St. Louis Aircraft renewed its efforts to get into the trainer-production business, especially with the World-War-I -fueled major buildup in military pilot-training programs. With its own funds, St. Louis Aircraft developed and flew in 1940 the PT-LM-4, a low-wing, all-metal primary trainer with a Ranger in-line engine. Although tested by NACA, the Army, and in Canada, the PT-LM-4 was not put into production. Instead, the Army gave St. Louis Aircraft production contracts for the similar Fairchild designed PT-19 trainer. During 1942-44, St. Louis Aircraft built and delivered 350 of these primary trainers, in two versions: the PT-19A (44), with a Ranger in-line engine, and PT-23/PT-23A (306), with a Continental radial. These trainers were all test-flown at St. Louis Aircraft’s own flying field, adjacent to the St. Louis Car factory on North Broadway in St. Louis. (This field was operated as a private airfield, Ross Airport, for a time after W.W. II.)

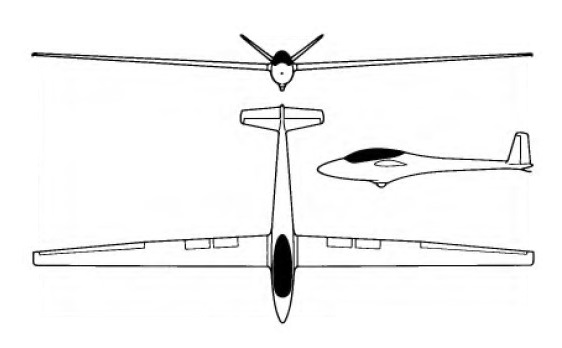

Having already placed large-scale aircraft production contracts with the major airframe builders, the Army sought to employ secondary sources when it decided in 1941 to develop a significant glider assault capability. Not being burdened at the time with aircraft production contracts, St. Louis Aircraft was invited to participate in the Army’s glider program, obtaining contracts to develop eight-place and fifteen-place troop-carrying gliders. The eight-place XCG-5 demonstrated serious aerodynamic flaws during its first test flights (at Lambert Field) in 1942. The redesign necessary to correct the aerodynamic, as well as significant structural, problems doomed the XCG-5. The larger, heavier XCG-6 was never built.

St. Louis Aircraft once again went dormant following the end of World War II. It disappeared forever when the parent company, St. Louis Car, closed its doors for the last time in 1973. The historical record, the St. Louis Car and St. Louis Aircraft corporate archives were given to Washington University, where they now reside.