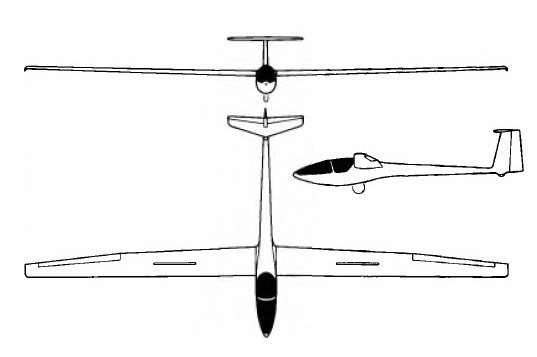

The DG-500 comes in a number of sizes which all share the same basic fuselage. The 500T Elan Trainer, which first flew in 1989 has an unflapped 18 m. wing without provision for water ballast; retractable gear is an option. The front cockpit design has been purposely made similar to that of the DG-300 Club. The higher performance versions (DG-500-22 Elan and DG-500 M) have a 22 m flapped wing and are, respectively, unpowered and self-launch models. The powered model (DG- 500M) has been liquid cooled Rotax powerplant on an electrically retracting pylon, digital engine instrumentation (DEI) and water ballast reduced to 100 kg 220 lb, and comes with an optional steerable nosewheel. The DEI, which has instrumentation in both cockpits, shows rpm, temperatures, pressures and fuel quantity as well as controlling the amount of fuel injected by the electronic fuel system. Engine retraction is automatic once the propeller has been stopped and centred. All 22m ships, which have a four piece wing, have retractable gear as standard. Performance of the 500M is similar to the 500/22 Elan, but empty and gross weights are 565 kg/ 1,246 lb and 825/1,819 lb respectively. All developed with 3 different sets of wingtips; 17.2 m for aerobatics, 18 m and (with winglets) 20 m. A flapped unpowered development of the DG-500/22 Elan. Known as the DG-500/20 Elan Winglets, has been designed for the German 20 m two-place contest class. This has the 750 kg/ 1,653 lb gross weight of the DG-500/22, and a wing loading of 45.0 kg/sq.m./ 9.22 lb/sq. ft. Manufacture of the DG-500 is partly by Elan in Slovenia.

Wing span: 18m / 59.1ft

Wing area: 16.6sq.m / 178.6sq.ft

Empty Weight: 390kg/ 860lb

Payload: 225kg / 496lb

Gross Weight: 615kg / 1356lb

Wing Load: 37.05kg/sq.m / 7.59lb/sq.ft

Water Ballast: 160kg / 353lb

Aspect ratio: 19.52

No. of Seats: 2

Structure: CFRP/GFRP

Airfoil: Wortmann FX-73-K-170/20 root; -170/22 tip

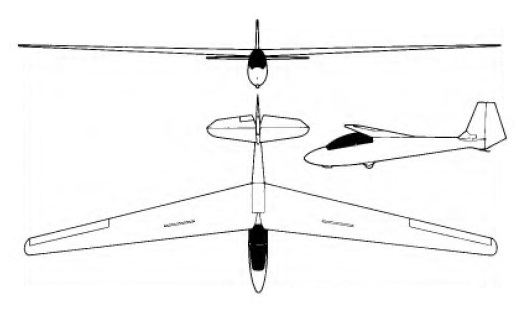

DG-500/22

Wing span: 15m / 49.2ft

Wing area: 10.95sq.m / 117.9sq.ft

Empty Weight: 255kg / 562lb

Payload: 270kg / 595lb

Gross Weight: 525kg / 1157lb

Wing Load: 47.94kg/sq.m / 9.82lb/sq.ft

Water Ballast: 180kg / 397lb

L/DMax: 40 @ 109 kph / 59 kt / 68 mph

No. of Seats: 2

MinSink: 80 kph / 43 kt /49 mph

Aspect ratio: 20.5

Airfoil: HQ-35; HQ 37 on tips extensions

Structure: CFRP/ aramid