Taylor Aircraft Company

Taylorcraft Aviation Company

Taylor-Young Airplane Company

Taylorcraft Aviation Corporation

C. Gilbert Taylor and his brother had first established the Taylor Brothers Aviation Corporation- slogan; “Buy Your Airplane Taylor Made” – in Rochester, New York, in 1926 to market the Taylor Chummy lightplane, a two-seat high-winged monoplane, priced at $4,000.

The Chummy failed to sell, and after Gordon died flying another Taylor design in 1928, Clarence moved to Bradford, Pennsylvania, where the townsfolk had offered him a new factory at the local airfield plus $50,000 to invest in the company. One of the investors was William Thomas Piper, who had made his money from oil wells.

More concerned about solvency than perpetuating his name, he re-organized the assets into the Taylor Aircraft Com¬pany, giving C. Gilbert Taylor half inter¬est in the new enterprise as an induce¬ment to stay on board. Piper handled the finances as the firm’s secretary and trea¬surer, while Taylor served as president and chief engineer.

After continuing with the Chummy for a time, Taylor abandoned the design and began work on a new inexpensive aircraft to compete with the heavier craft common at the time. A battle between engineer and businessman caused a rift between the two. Piper took advantage of Taylor’s absence during an illness, and instructed Taylor’s junior engineer Walter Jamouneau to modify the Cub, in Models E-2 and F-2, to be more attractive and marketable. Taylor returned from his illness and left the company in 1936; and Walter Jamouneau took over as chief engineer.

A disastrous factory fire brought production of the Cub J-2 to a halt. When the company ran into financial difficulties, manufacturing and marketing rights for the Taylor Cub, which had first flown in September 1930, were acquired by W. T. Piper in 1935 for $761, who in 1937, formed Piper Aircraft Corporation to continue production of this aircraft. It was placed back in production as the Piper J-3 Cub.

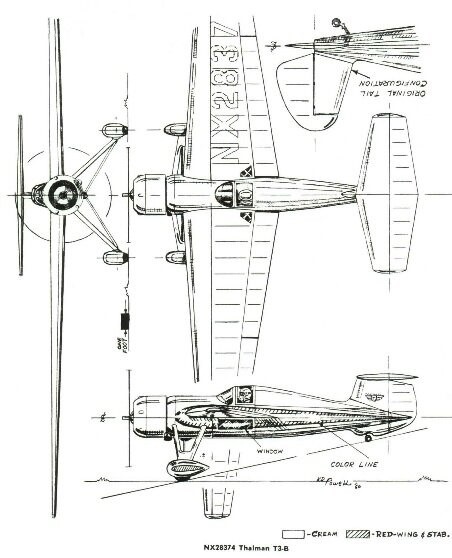

Taylor vowed to build a personal aircraft superior to the Cub. Taylor formed his own company in 1935 as Taylor Aircraft Company at Alliance, Ohio, renamed Taylor-Young Airplane Company, then Taylorcraft Aviation Corporation in 1940. In 1936 Taylor rented facilities at Pittsburgh-Butler Airport and first manufactured the “Taylorcraft” plane. Main pre-war lightplanes were Models B, C and D, of which C and D formed basis for formation of Taylorcraft Aeroplanes (England) Ltd. Taylor gave his airplane a closed cabin with doors and a control wheel instead of a stick. The fat, side by side T Craft was faster than a tandem Cub. It set speed, distance and altitude records for light airplanes. No Taylorcraft has a number below 25. They figured nobody would want an airplane from a company that had built only three or four.

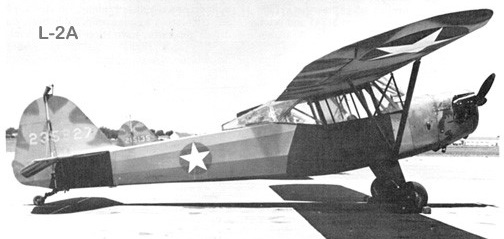

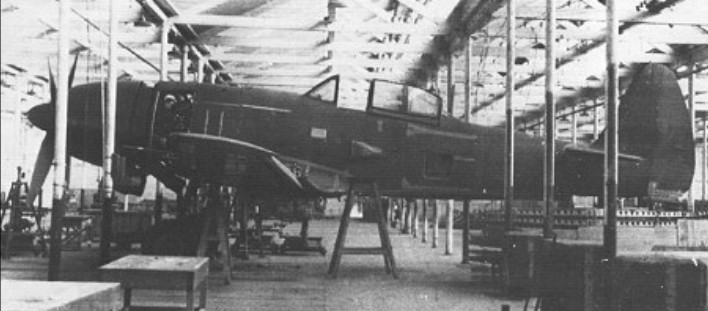

During WWII, light aircraft were used for training, liaison, and observation purposes. Taylorcraft’s DCO-65 model was called the L-2 by the United States Army Air Forces and served alongside the military version of the Piper Cub in WW2. Built over 1,900 similar L-2 Grasshoppers for USAAF, TG-6 training gliders based on L-2, and components for Consolidated PBY, Curtiss C-46 and Douglas A-26.

In November 1938 the company established its Taylorcraft Aeroplanes (England) Ltd as its British subsidiary, based in Thurmaston, Leicestershire, England. British production was mainly of the Plus C and Plus D models, and in 1939 the Royal Air Force impressed 24 of the 32 aircraft for evaluation as observation and artillery spotter aircraft. The evaluation confirmed the soundness of the concept, and a derivative of the Plus D was ordered into production as the Auster Mk 1. This entered service in August 1942. The military chose the name “Auster”, which translates as a warm or gentle breeze, possibly from the south. Thus Taylorcraft Plus D built for the army became Auster Mk 1. After the war, Auster Aircraft Ltd was formed and commenced a series of variations on the basic theme until 1960 when it was absorbed into Beagle Aircraft Ltd.

Taylorcraft Aeroplanes Ltd developed the Taylorcraft Model ‘D’ and the Auster Mk. I through Mk. V, which became the backbone aircraft of the British AOP (Air Observation Post) and the three Canadian AOP squadrons, No. 664 Squadron RCAF, No. 665 Squadron RCAF, and No. 666 Squadron RCAF.

Built some 2,800 Model B-12Bs in 1945-1946, but in the fall of 1946 production was halted following a fire in the Taylorcraft factory at Alliance, Ohio and the company went into bankruptcy. Re-formed in 1947 as Taylorcraft Inc, producing models BC-12D, Ace, Traveler, Topper, Ranch, Wagon, Tourist, Sportsman and Special de Luxe.

In 1949 C.G. Taylor bought the assets from the former company, and started a new company Taylorcraft, Inc. at Conway, Pennsylvania. The company restarted production of the BC-12D Traveller and the BC-12-85D Sportsman. The company produced few aircraft and the type certificates were sold to Univair and production was halted.

The factory moved to Pittsburgh in 1954 but then ceased manufacture four years later. It was re-formed again in April 1968 as Taylorcraft Aviation Corporation, and from 1973 resumed production of an updated two-seat Sportsman 100.

In 1971 the Taylorcraft Aviation Corporation, owned by Charles Feris put the Model 19 back into production as the F-19 Sportsman and added the F-21 model. Feris died in 1976 and the production continued at a low rate until 1985. Charles Ruckle bought the company in 1985 and he moved the operation to Lock Haven, Pennsylvania, where the company produced 16 aircraft before it went bankrupt in 1986 and the company was offered for sale.

Company ceased trading 1986, and in 1989 was purchased by West Virginia based Aircraft Acquisition Corporation, developed a series of two/three-seat lightplanes under the F22 designation. From 1992 operated independently of AAC and took name of Taylorcraft Aircraft. The assets were sold to key investor East Kent Capitol.

1990: Taylorcraft Aircraft corporation, PO Drawer 3350, Morgantown, WV 26505, USA.

John Polychron, former CEO of Del Monte Foods purchased Taylorcraft and operated it for approximately one year until he sold it to Philadelphia Attorney Phillip O’Rielly. O’Rielly never reopened and the company became deeply in debt resulting in a Sheriff’s sale in 1996.

Taylorcraft was saved from extinction by Lee Booth, a former Marine and an engineer from Seaford Delaware. Booth renamed the Company Booth-Taylorcraft Aerospace, Inc. Booth-Taylorcraft Aerospace paid all creditors in full and relocated the entire company in 88 53 ft long truck trailers to Greensboro, North Carolina.

Booth, as Chairman and President, directed the Corporation through an extensive recertification of all type certificates, engineering, FAA audits up to the Aircraft Certification Office level, production procedures, complete re-tooling and certification of tooling and work processes. Booth enlisted the assistance of Darrell C. Romick, former Chief Engineer of Taylorcraft Airplane Company and of BF Goodrich. Romick was a close associate of Wernher von Braun and worked for Goodyear Aircraft in the 1950s.

Booth-Taylorcraft Aerospace, Inc became a contractor to numerous governments for military aircraft, weapons systems and firearms. Booth was the first Taylorcraft owner in the company’s history to keep the company debt free the entire time he operated it. In March 2000, Booth formed a strategic partnership by selling half of the Civil Aircraft Division to Harvey Patrick of Pats, Inc. Booth retained all military items, UAVs, several type certificates, designs and patents. The Small Aircraft Division was moved to Georgetown, Delaware at the Sussex County Airport. Booth and Patrick then formed Taylorcraft 2000, LLC and served as Co-chairmen. Booth eventually sold his half to Harvey Patrick and Taylorcraft 2000, LLC was owned by the Harvey and Vera Patrick Foundation. In 2003 The Harvey and Vera Patrick Foundation sold the company to Harry Ingram, with 100% financing.

Harry Ingram, moved the plant to La Grange, Texas in 2003 and on April 25, 2005 it was announced that the factory was moving again to Brownsville, Texas and outsourcing the labour.

On February 21, 2008 the company was repossessed by its former owner, Taylorcraft 2000 LLC. The previous owners had taken orders for new struts for existing aircraft to alleviate a repetitive inspection Airworthiness Directive and was delivering struts to customers. The design’s type certificates, drawings, jigs, templates and parts were put up for sale.