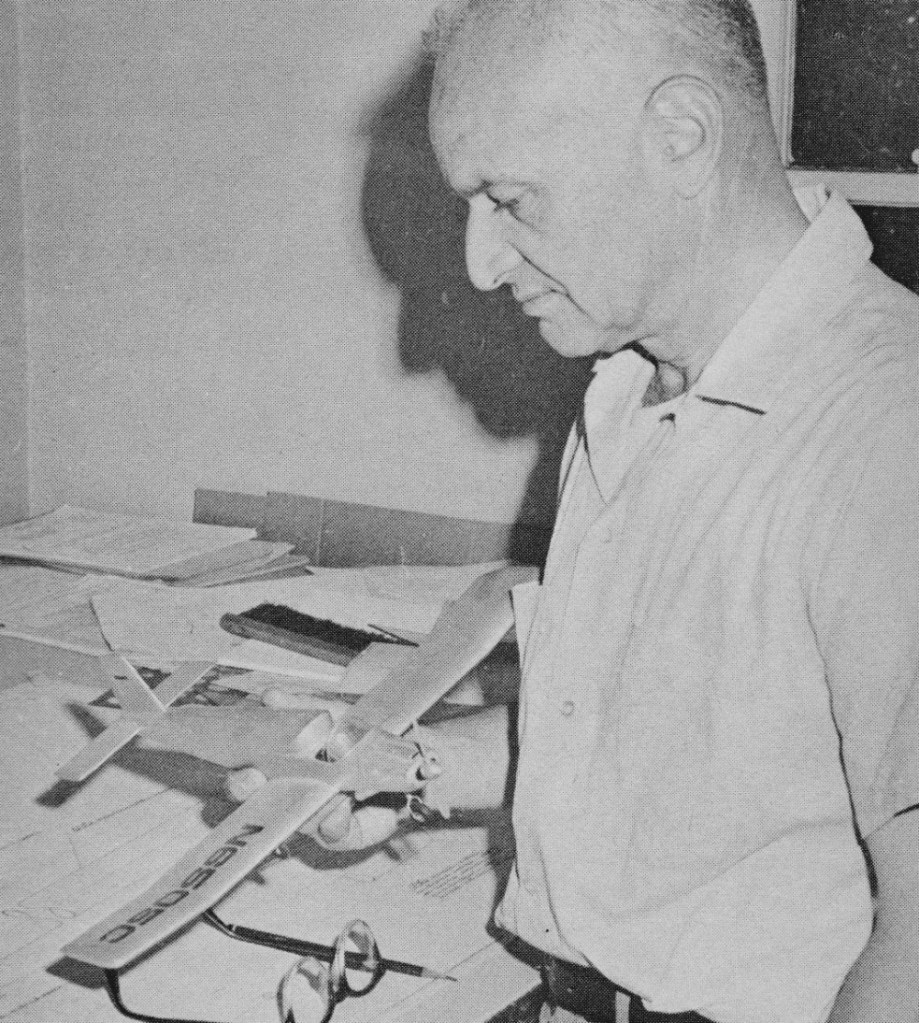

Born in 1888, Andrei N Tupolev was an early pupil, at the Moscow Technical High School, of the internationally famous aerodynamicist, Professor N E Zhukovski. His studies and early gliding experiments were, however, interrupted in 1911 when he was arrested for revolutionary activities. During part of the first World War, Tupolev worked in the Duks aircraft factory in Moscow, then the largest in Russia.

Andrei Tupolev Article

After the Bolshevik Revolution, Tupolev became one of Zhukovski’s leading assistants in setting up the Central Aero and Hydro dynamics Institute (TsAGI). This brought together pre war Russian research establishments with other, newly created bodies, and in 1920 Tupolev became head of its design department (AGO) and president of commission to design and build all-metal aircraft 1922.

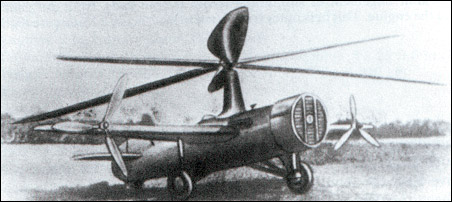

Initially followed Junkers formula, using corrugated metal skins; first to appear were ANT-1 and ANT-2 (A. N. Tupolev) cantilever monoplanes. Became head of AGOS department of the Moscow TsAGI in 1922; during 1920- 1936 most designs bore ANT designations although some emanated from his design team leaders, chief deputy A. A. Archangelskii, W. M. Petlyakov and P. O Sukhoi (e.g. Sukhoi designed ANT-25 and 37).

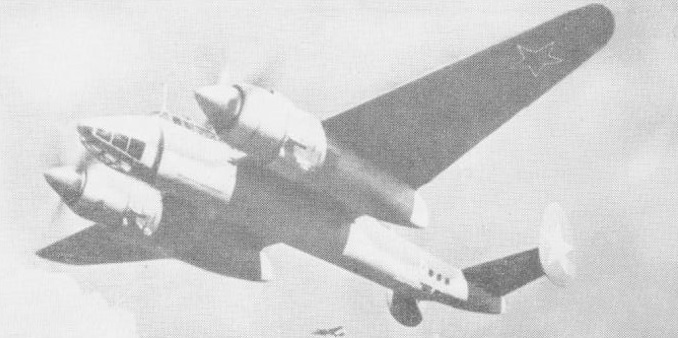

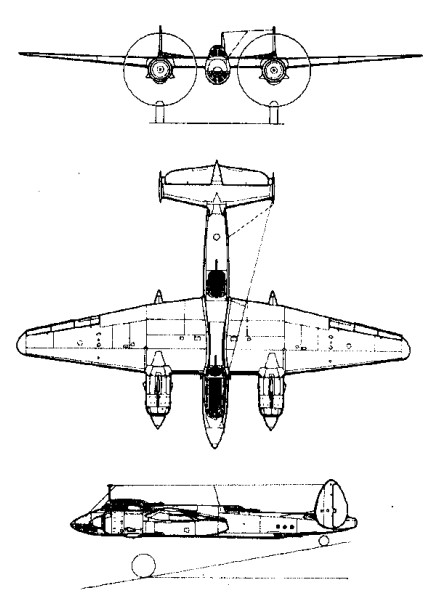

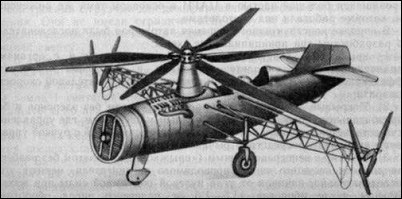

Tupolev’s first major design was ANT-4 (TB-1) heavy bomber of 1925, forerunner of several very large machines including ANT-6 (TB-3) bomber; ANT-9 commercial passenger transport and huge ANT-20 Maxim Gorkii propaganda aircraft of 1934. Also designed ANT-40 (SB-2) twin-engined medium bomber.

The enormous creativity of the Tu¬polev group stemmed in part from this designer’s ability to train and direct others, such as Sukhoi and Petlyakov. Petlyakov, for example, was responsible for the PE 8, a four en¬gine bomber that was larger and more powerful than the B 17.

In 1936 Tupolev was arrested during Stalin’s purges and condemned to death, but sentence commuted and after some five years’ imprisonment was released and restored to favour (ostensibly in recognition of Tu-2 medium bomber, designed while in prison) and given his own design bureau. After Second World War continued to place emphasis on large aircraft; Tu-4 copy of Boeing B-29 Superfortress helped win him a Stalin Prize in 1948.

Main early post-war products included Tu-14 twin-jet naval medium bomber; Tu-16 intermediate-range twinjet bomber (first flown April 1952; also produced in China as the Xi’an H-6); and a quartet of four-turboprop swept-wing giants: the Tu-95 long-range strategic bomber (first flown November 1952 and built up to 1992), Tu-142 naval variant for long-range antisubmarine warfare and communications relay (first flown June 1968), Tu-114 200-passenger transport based on Tu-95 (first flown November 1957) and Tu-126 AWACS aircraft (first flown 1962).

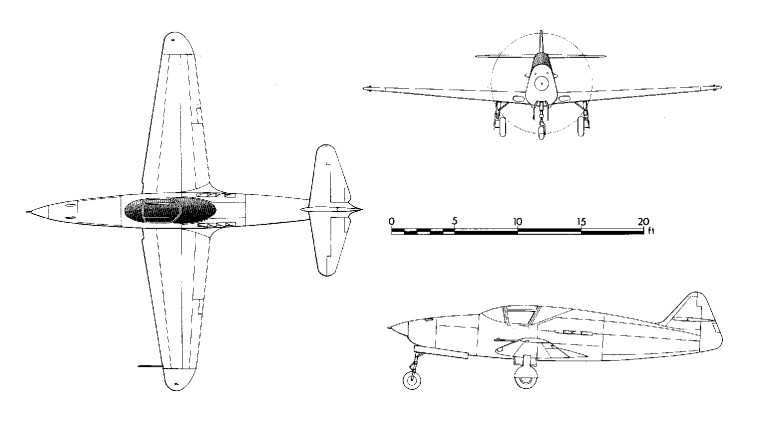

Later military types included the twinjet Tu-22, the first Soviet supersonic bomber that first flew in 1959, and the Tu-128 very large all-weather interceptor (first flown March 1961), the variable-geometry wing Tu-22M Backfire intermediate- range Mach 1.8 bomber and missile launcher (first flown August 1969 and 514 built during 1971-90) and the variable-geometry wing Tu-160 Blackjack heavy missile bomber with a speed of Mach 2.05 and range of over 12,215km without in-flight refueling (first flown December 1981 and entered Soviet service from 1987), while projects include the Tu-204P maritime patrol derivative of the Tu-204 airliner, Tu-2000 hypersonic bomber, and a subsonic strealth bomber.

Early turbojet and turbofan powered transport aircraft included twin-jet Tu-104 (based on Tu-16 and first flown June 1955); Tu-124 (first flown March 1960); Tu-134 (first flown July 1963) and tri-jet Tu-154 (first flown October 1968). Tu-144 became, in December 1968, the first supersonic airliner in the world to fly. It exceeded Mach 2 for the first time in May 1970 and was the first of its type to enter regular service when, in December 1975, it began freighting for Aeroflot prior to initial passenger services in 1977. However, Tu-144 was not a success and services were terminated in June 1978; in November 1996 a converted Tu-144D flew again as the Tu-144LL, used thereafter for an international High-Speed Civil Transport research program to assist in the development of a nextgeneration supersonic transport.

Most recent Tupolev commercial transports, programs and projects include the convertible cargo/passenger Tu-130 (to fly on standard and liquid natural gas in the 21st century), Tu-136 projected light passenger/cargo transport with twin Pratt & Whitney turboprop engines, Tu- 155/Tu-156 conversions of Tu-154 to use cryogenic fuel engines (Tu-155 for research flew 1988), Tu-204 medium-range airliner for typically 214 passengers (first flown January 1989) and its projected Tu-206 cryogenic fuel derivative, Tu-214 and Tu-224 airliners based on Tu-204 but featuring increased take-off weights and longer range (first flight of Tu-214 March 1996), Tu-230 projected light/medium freighter, 166-passenger Tu-234 airliner as a short-length variant of Tu-204, Tu-244 projected supersonic airliner, Tu-304 and Tu-306 (cryogenic fuel variant) projected long-range airliners for up to 392 passengers, projected Tu-324 regional and business transport, Tu-330 and liquid-gas Tu-338 freighters, Tu- 334 medium-range airliner for typically 102 passengers (first flown February 1999) and its Tu-336 cryogenic fuel derivative, Tu-404 projected giant 850-seat airliner, and Tu-414 projected 70-passenger regional jet.

Tupolev general-aviation projects include Tu-34 pressurized five/seven-seat STOL transport with twin turboprop engines and pusher propellers, Tu-54 single-seat agricultural monoplane, Tu-400 eight/ten-seat business jet with regional airliner potential, and Tu 4X4 four/seven seat business jet as smallest aircraft in the Tu- 324/400/414 range.