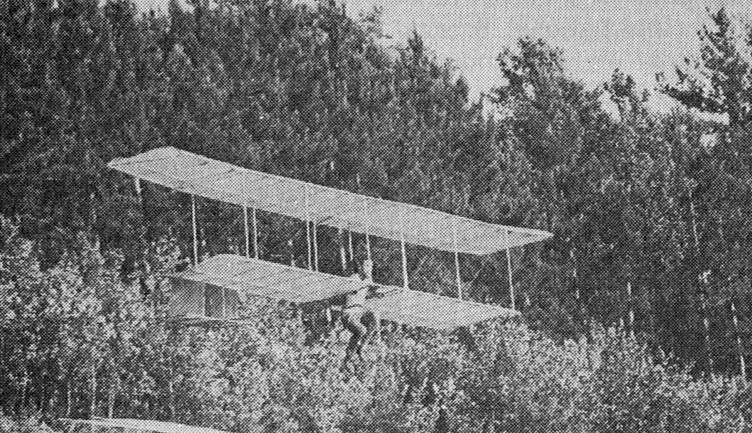

Michael A. Markowski built an experimental hang glider in 1971 as a canard stabilised kite. It made the stall more gentle and dive recovery automatic.

Michael A. Markowski built an experimental hang glider in 1971 as a canard stabilised kite. It made the stall more gentle and dive recovery automatic.

In the ski areas of New England, USA, Terry Sweeney of New Hampshire experimented with some Chanute typ. He and some friends made many flights, learned much and had fun. Their gliders replaced the older airfoils with more modern versions.

On the east coast, USA, in the summer of 1970, Robert G. Mixon of Miami, Florida, built and flew a Chanute-type biplane based on a plan found in a 1909 Popular Mechanics.

The local paper ran a front page headline “Those Magnificent Men In Their Flying Machine” on 15 June 1970. A local TV station even took some footage of a cliff launch. Mixon did it out of frustration due to the high cost of conventional flying.

Later, he offered plans, because of a large number of requests for his story which appeared in the February 1971 issue of Sport Aviation.

Richard Miller and his Conduit Condor was the highest performing hang glider at the first Universal Hang Glider Championships of 23 May 1971.

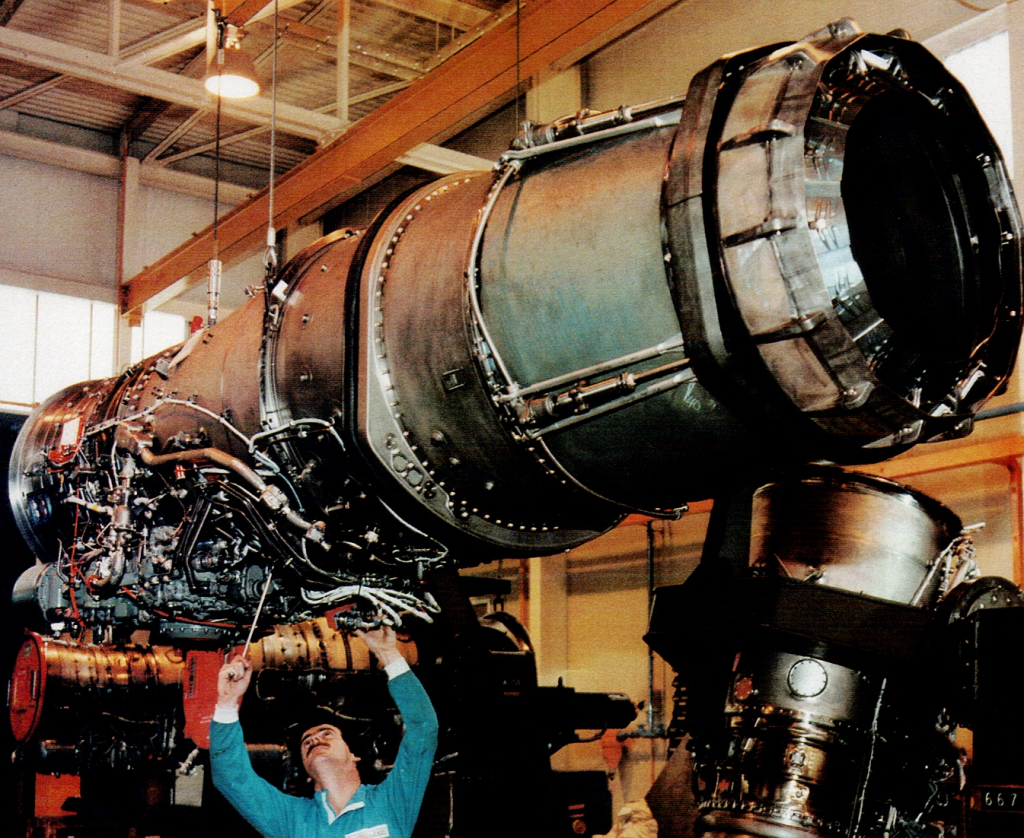

The Turbo-Union RB199 is a turbofan jet engine designed and built in the early 1970s by Turbo-Union, a joint venture between Rolls-Royce, MTU and Aeritalia.

The RB199 originated with a requirement, in 1969, to power a new European multirole combat aircraft (MRCA) called the Panavia MRCA. The engine requirements to meet the Panavia MRCA specification were significant advances over current engines in thrust-to-weight ratio, fuel consumption and size. The final selection of the engine for the MRCA was made between a new European collaboration, Turbo Union, with the RB199, and Pratt & Whitney who proposed the JTF16. The Panavia MRCA would later be called the Panavia Tornado.

Advanced engine studies at Bristol Siddeley had already been done to support the BAC/Dassault AFVG and were based on the Pegasus two-spool arrangement. At Rolls-Royce, where the three-shaft RB211 engine was in development, three shafts were considered better. Rolls-Royce took over Bristol Siddeley in 1967 so the configuration for the RB199 was decided, a three-shaft engine, but fundamentally to Bristol’s design and Bristol’s higher technology.

The overall design concept for the international collaborative program, three shafts was decided by Rolls-Royce. The bypass ratio was chosen for long-range, with low fuel consumption, particularly when throttled back. The selected BPR also gave a higher reheat boost than with smaller values used on similar engines. The design of the individual modules was shared between Rolls-Royce, MTU and Fiat according to their existing expertise. Rolls-Royce designed the fan using scaled-down Pegasus knowledge, the combustor, the high pressure (HP) turbine and the reheat. The reheat used cold air combustion techniques, described by Arthur Sotheran and which were derived from their experience with ramjets and plenum chamber burning (PCB) in Pegasus front nozzles. Fiat had built turbines for the Viper so designed the low pressure (LP) turbine as well as the final nozzle. MTU designed the intermediate pressure(IP) and high pressure (HP) compressors, the IP turbine, and the thrust reverser.

A three-spool arrangement reduces the pressure ratio on each compressor so no variable stators were needed. To meet the short afterburner requirement an arrangement known as mix-then-burn, as used in current engines, was not possible because it was too long and heavy. The RB199 used a much shorter arrangement known as mix/burn.

The RB199 first ran on 27 September 1971 at Patchway, UK. It was flight-tested using an Avro Vulcan with the engine installed in a nacelle that was representative of the Tornado aircraft. The Vulcan first flew with the RB199 in 1972.

Service flying with the Royal Air Force, German Navy and German and Italian Air Forces in the European environment showed normal failure mechanisms for turbine blades, thermal fatigue, creep and high cycle fatigue (HCF) so development started on replacing the initial production equiaxed blades with single-crystal ones which last longer at high temperatures.

Sand ingestion tests had been done and passed as part of the qualification for service introduction but operating in desert conditions with the Royal Saudi Air Force produced new problems. Frequent flying in air carrying different sizes of sand particles caused deposits on the HP turbine blades from sand passing through the combustor. In addition, sand carried with the cooling air through the blades blocked the cooling holes. Single crystal blades were being introduced to improve the life of the blades for the European operating conditions and revised cooling hole arrangements were introduced at the same time to reduce the detrimental effect of sand on blade cooling. With incorporation of these blade processing and cooling changes “Desert Storm Tornado aircraft flew some of the most arduous missions of any Allied aircraft with reliability no worse than peacetime and no engines were rejected for HP Turbine blade defects.”

Looking back on the RB199 program in 2002 Chief Engineer for the RB199, Dr. Gordon Lewis, concluded “The final production standard provided satisfactory reliability and performance.

Variants and applications

RB199 Mk 101

Initial variant powered first Tornado IDS deliveries, with a 38.7kN (8700lbf) dry thrust, 66.01kN (14840lbf) with afterburner.

RB199 Mk 103

Powering Tornado IDS strike versions, with a thrust rating of 40.5 kN (dry) 71.2 kN (reheat)

RB199 Mk 104

Powering the Tornado F3 Air Defence Variant, with a thrust rating of 40.5 kN (dry) 73 kN (reheat)

RB 199 Mk104D

Derivative used on the BAe EAP.

RB199 Mk 105

Powering Tornado ECR versions and applicable to IDS, with a thrust rating of 42.5 kN (dry) 74.3 kN (reheat)

RB199-122

A derivative of the Mk104 (originally designated Mk 104E[13]), powering the first two prototypes of the Eurofighter Typhoon (DA1 and DA2) until the initial versions of the Eurojet EJ200 were available.

Specifications (RB199-104)

Type: Turbofan

Length: 3,600 mm (142 in)

Diameter: 720 mm (28.3 in)

Dry weight: 976 kg (2,151 lb)

Compressor: 3-stage LP, 3-stage IP, 6-stage HP

Turbine: Single-crystal HP, single-crystal IP, 2-stage LP

Maximum thrust: 40 kN (9,100 lbf) dry, 73 kN (16,400 lbf) wet

Turbine inlet temperature: ~1,600 K

Thrust-to-weight ratio: 7.6 (with reheat)

1966 Formula 1 Racer Pusher Type Experimental

This is a 1966 formula 1 racer pusher type experimental, the aircraft is a stressed skin design with cantilever wing construction and twin booms to accomodate pusher engine and conventional landing gear. The entire airframe components, internal structure, and all skin surfaces are made from 2024-T3 alclad aluminum, wingspars are of 2024 -T3 aluminum web with extruded spar cap top to bottom.The cockpit area is formed of half hard aluminum.The canopy is formed of plexiglass, all fittings are welded chromoly, all flight controls are cable operated except ailerons these are push type controlled.Engine is a O-200 or C-85.

It was built for the Goodyear races, by three engineers who passed away together in an airline accident and the aircraft was never finished or flown.

Henry Guantt later purchased this aircraft from a Mr. Watts in 1973.

This aircraft was then aquired by a father and son team around 2006 for the purpose of fixing and flying the aircraft but that never came to be because the father passed and they never got to finish this project. Around 2012 the craft was again on the market, hoping someone could dedicate the time to it and fly it. This included all of its documentation and specs and all of the parts to complete it except the engine but including the pusher type propeller.

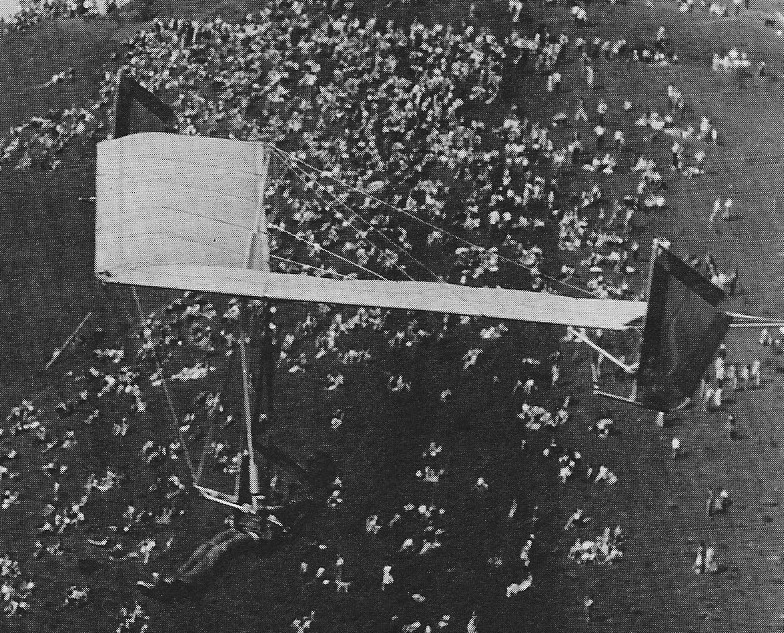

Breanewave hang glider

An early flying wing hang glider. The British Breanewave.

Curtiss-Wright, the very first licencee of the Wankel RC engine, developed the RC2-90-Y2 Wankel RC aircraft engine, which displaces 90 cu.in twice per shaft revolution, and develops 310 bhp at 6000 rpm.

Circa 1967 Fichtel & Sachs AG developed the Wankel KM 48 into an auxiliary power unit for sailplanes.

The 10 bhp engine uses normal grade petrol with 2% by volume of added lubricating oil.

The first installation was in a Ka8 single seat sailplane. The Wankel KMA8 is mounted on a single upward projecting tube above the aircraft C of G. A 31.5in diameter Hoffman pusher propellor is mounted directly on to the output shaft. Engine cooling and appearance are enhanced by a polyester resin glassfibre cowling. The engine, cowling and 1.1 Imp.Gal of fuel weight 38.6 lb.

The test programme showed at a steady 5000 rpm and a forward speed of 40.5 mph, the Ka8 was climbed at up to 140 fpm at around 6500 ft. Maximum level speed was 59 mph.

Fichtel & Sachs believe that 800-1000 between overhauls could be expected.

Displacement: 160 cc

Output: 10 bhp at 5,000 rpm

Engine weight: 18.74 lb