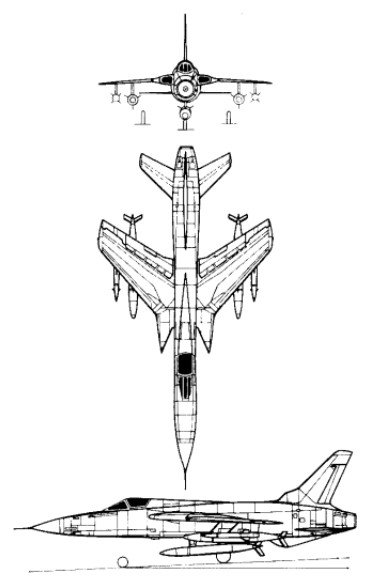

In 1951 Republic began private venture develop¬ment of a single seat tactical fighter bomber which the company anticipated would be a successor to the F 84F Thunderstreak. The F-105 Thunderchief, or company model AP-63. Alexander Kartveli’s design team originally intended a straight fuselage for the craft but, after seeing NACA data assembled by Richard Whitcomb, was won over by the wasp-waist or ‘area rule’ configuration which enhanced transonic flight performance. At first intended for the Allison J71 engine and powered in prototype form by the Pratt & Whitney J57, the F-105 attained its successes with the 7802kg thrust Pratt & Whitney J75-P-19W turbojet which provided 11113kg thrust with afterburning. Its mid-mounted wing, swept 60 degrees, and the F-105 stood high on its tricycle gear.

Republic F-105 Thunderchief Article

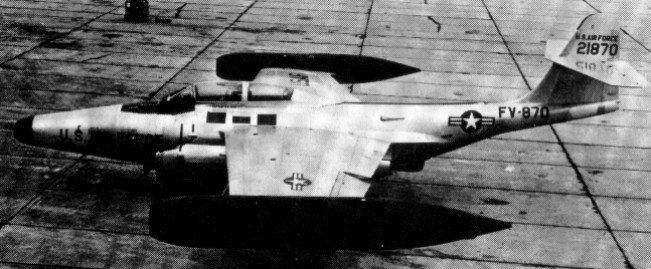

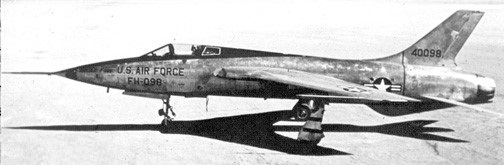

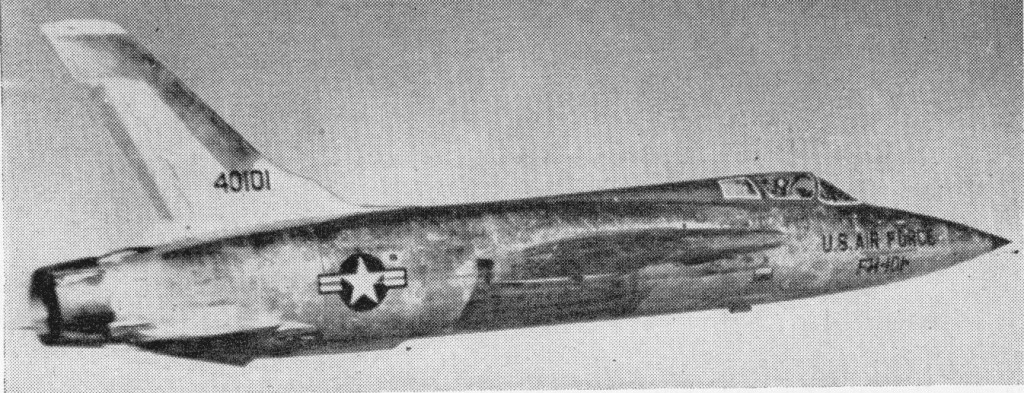

Development began when two J57-powered YF-105As commenced flying 22 October 1955, soon followed by 15 aircraft designated JF-105B and F-105B for test programmes.

The two 1955 YF-105A, 54-0098 and 54-0099, were service testers with 15000 lb P&W J57 engines. The first flew on 22 October 1955, piloted by Russell M Roth.

The F-105A was not built in favour of the F-105B. Three RF-105A photo-recon version were built in 1956.

Production F-105Bs, long delayed by development problems, began to roll from Republic’s Farmingdale line during 1958 and the USAF accepted its first machine on 27 May 1958. The 335th Tactical Fighter Squadron, temporarily moved to Eglin AFB, Florida, began to work up in the new aircraft only to find that, given its complexity and production slippages, it would not become operational until 1960. Meanwhile, a two-seat strike variant, the F-105C, had reached the mock-up stage but was not built.

Though technical problems persisted and critics were calling the ‘Thud’ a maintenance nightmare, Republic proceeded with the F-105D variant which afforded true, all-weather capability by introducing General Electric FC-5 fully integrated automatic flight fire-control system.

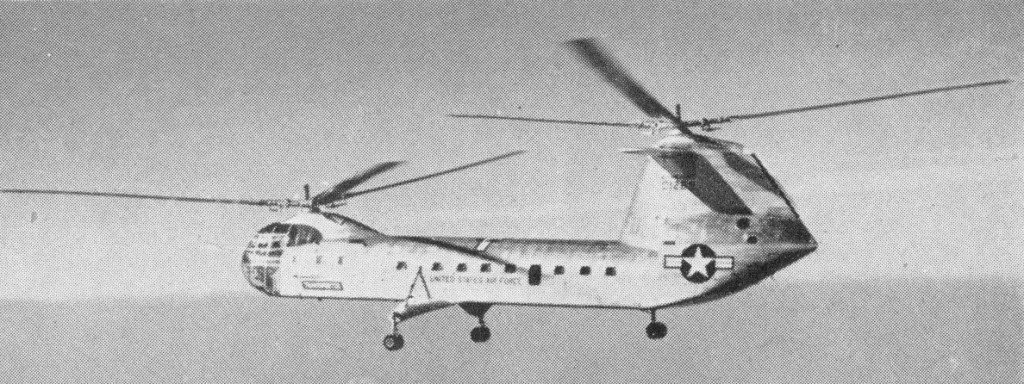

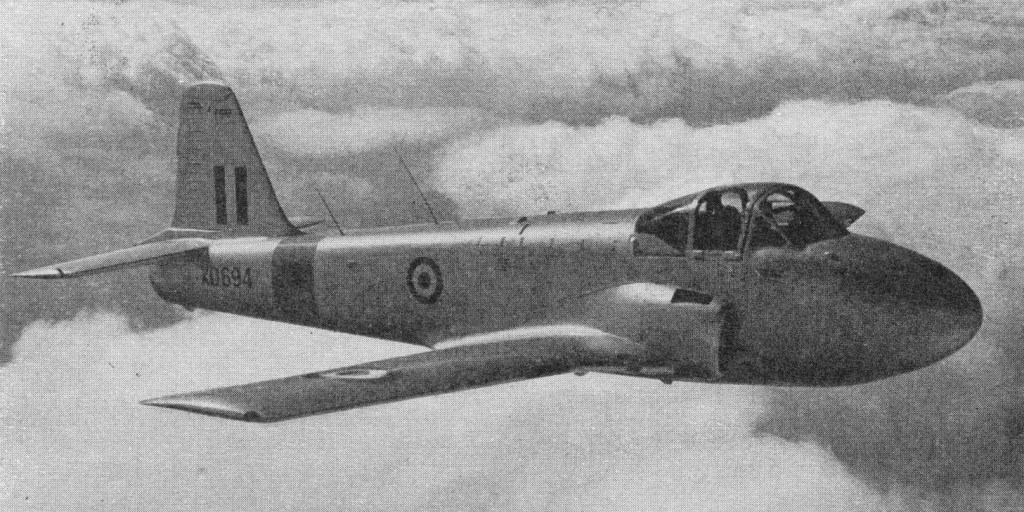

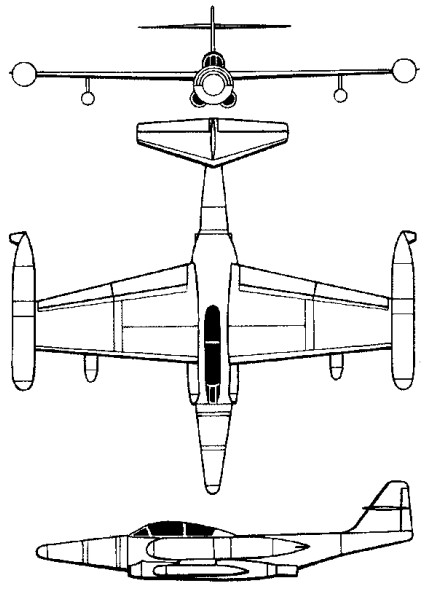

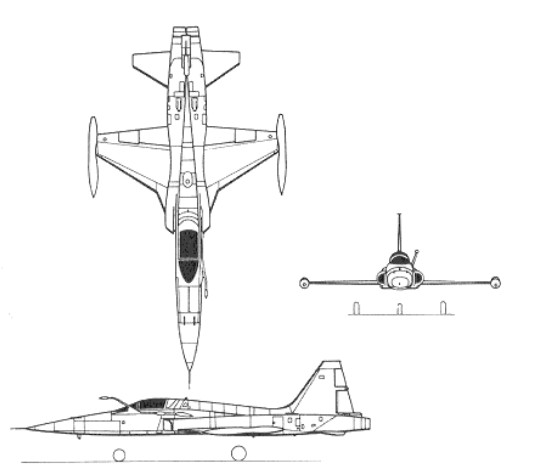

The F-105 has mid-set sweptback wings, sweptback tail surfaces, and a one-piece all-moving tailplane mounted low on the fuselage and with a ventral stabilising fin. The ailerons are used only at low speeds and the main roll control is by five section spoilers forward of the large slotted flaps on each wing. The leading edge is variable-camber. ‘Clover-leaf’ air brake is around the exhaust nozzle. Each undercarriage leg has a single wheel, the mains retracting into the wings and nose wheel retracting forward.

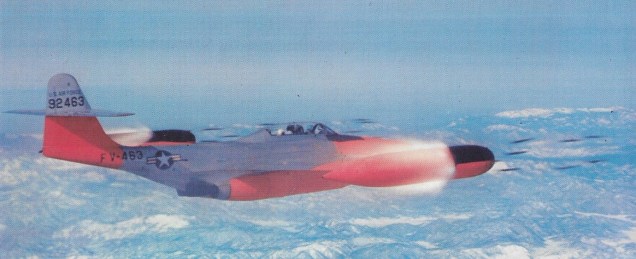

The F 105D was powered by a Pratt & Whitney J75 P 19W turbojet engine that develops 26,500 lb thrust (with after¬burning). The F-105D’s fuselage was lengthened by 0.381m. Some 610 were manufactured, and first flight took place at Farmingdale 9 June 1959. The F-105D model soon equipped all three squadrons of the 4th Tactical Fighter Wing at Seymour Johnson AFB, North Carolina. United States Air Forces in Europe (USAFE) were the first overseas recipient of the F-105D, the 36th TFW at Bitburg AB, West Germany re-equipping from 12 May 1961 and the 49th TFW at Spangdahlem soon following. In the early 1960s, with a war growing in Asia, F-105Ds joined the 18th TFW at Kadena AFB, Okinawa.

The F-105D was by now a proven ordnance-carrier. More than 14,000 lb (6,350 kg) of weapons can be carried on under fuselage/wing stations. An internal weapons bay was also provided, and both conventional and nuclear weapons can be deployed. With multiple ejector racks (MER), it could carry an impressive load of external fuel, ECM gear, and eight 340kg bombs on long-range missions. The F-105D could also operate with the Martin AGM-12 Bullpup air-to-surface missile, which was to prove remarkably ineffective against ‘hard’ targets in Vietnam and would be observed bouncing off the Thanh Hoa Bridge. In addition, the F-105D model could carry 70mm rocket pods, napalm canisters and the AIM-9 infra-red (IR) air-to-air missiles, while its integral M61A1 Gatling-type 20-mm cannon proved invaluable in the dual roles of air-to-air combat and air-to-ground strafing. A late-model variant of the F-105D was the F-105D T-Stick II fitted with additional avionics which bestowed all-weather bombing capability, housed in a prominent dorsal fairing extending along the spine of the fuselage to the tail.

The F-105E was another two-seat variant that was not developed.

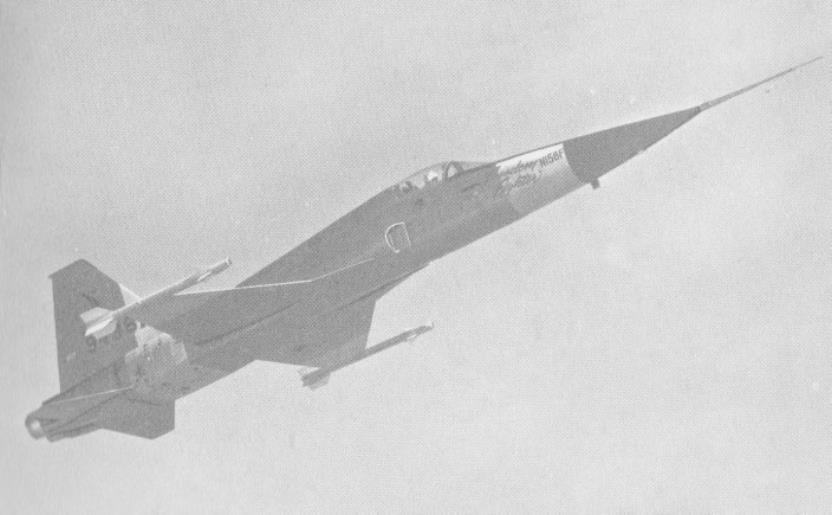

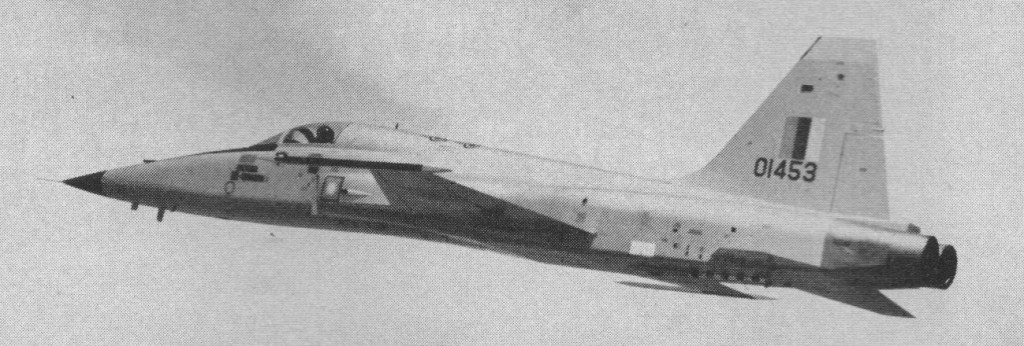

In May 1962 Republic proceeded with the tandem two seat F-105F. The first aircraft of this type (62 4412), which made its first flight 11 June 1963, was some 900kg heavier as well as slightly longer than earlier Thunderchiefs in order to accommodate the second crewman in tandem. The second F 105F, which flew for the first time on July 25 1963, flew thirty seven demonstration flights from Andrews AFB on August 18th, turn¬around being consistently completed within twenty minutes. The performance of the two seat F 105F is within 3% of the single-seat F-105D.

The two seat F 105G, developed from the F 105F combat/trainer version, carries advanced ‘Wild Weasel’ equipment to detect emissions from enemy radar sites, controlling surface-¬to air missiles, and missiles which can destroy the sites.

143 F-105Fs were delivered and 61 were later reconfigured for the electronic warfare or ‘Wild Weasel’ role in Vietnam, at first under their original designation and later as the F-105G.

After cancelling all airshows for two big summer months the Airforce Thunderbirds reverted back into F-100s in August 1965 to complete the season. They had started in Republic F-105s but a series of accidents throughout the Air Force grounded all Thunderchiefs.

The F-105D, F-105F and F-105G all fought in North Vietnamese skies, the F-104D model fighter-bomber so extensively that over half of the 610 built eventually fell to Hanoi’s air defences. After withdrawal from South East Asia in 1969-70, the Thunderchief soldiered on in Reserve and Air National Guard units, eventually flying its final sortie in 1984. At one time no fewer than 14 USAF and 11 ANG squadrons operated the type, which was built to the extent of 833 examples. Perhaps because of its complexity, no F-105 was ever exported.

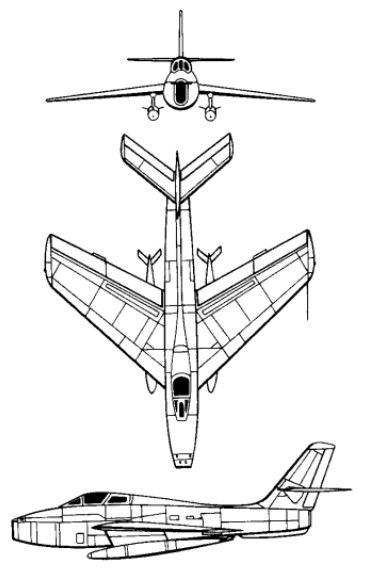

F-105B

Engine: 1 x Pratt & Whitney J75-P-5, 25,000 lb

No built: 75

F-105D

Engine: 1 x Pratt & Whitney J75-P-19W, 76.5kN / 26,500 lb reheat

Wingspan: 10.59 m / 35 ft 9 in

Wing area: 35.77 sq.m / 385.02 sq ft

Length: 19.61 m / 64 ft 4 in

Height: 5.97 m / 20 ft 7 in

Max take-off weight: 23967 kg / 52838 lb

Empty weight: 12474 kg / 27501 lb

Fuel capacity: 1000 Imp.Gal

Aux fuel weapons bay: 290 Imp.Gal

Underwing & fuselage fuel: 3 x 375 Imp.Gal

Max. speed: 1208 kt / 2237 km/h / 1420 mph / M2.15 at 36,000 ft

Cruising speed: 508 kt / 940 km/h

Ceiling: 12560 m / 41200 ft

ROC: 34,500 fpm

Range w/max.fuel: 3846 km / 2390 miles

Crew: 1

Armament: 1 x 20mm cannon, M61 Vulcan/1029rds, 6350kg of weapons

Hardpoints: 6

Inflight refuel: yes