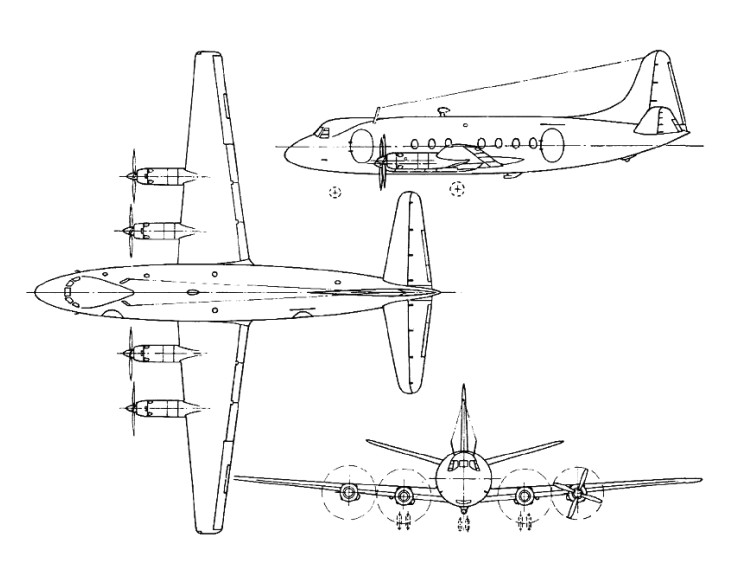

Under the project designation P.10, Westland began to study early in 1944 a long-range shipboard day fighter for Naval use, with the added capability of carrying a torpedo, rockets or bombs for anti-shipping strikes. Around this proposal, Specification N. 11/44 was written, and, in November 1944, a contract was confirmed for six prototypes (including two in land-based RAF configuration to Spec F.13/44). Redesignated W.34, and subsequently named the Wyvern TF Mk 1, the Westland aircraft was a low-wing monoplane of relatively conventional layout, but larger and heavier than any previous British single-seat Naval fighter. It had upward-folding outer wing panels with hinged tips, and a 3500hp Rolls-Royce Eagle 24-cylinder liquid-cooled H-type engine driving eight-blade contraprops. Provision was made in the design for the later introduction of a turboprop engine, such as the Rolls-Royce Clyde. Basic armament comprised four 20-mm Hispano Mk V cannon in the wings, with the possibility of carrying a 46cm Mk VIII torpedo under the fuselage three 464kg bombs or eight 27kg rocket projectiles.

Only 15 aircraft were built with the Rolls Royce Eagle (2700 hp) fitted.

In August 1946, an order for 20 pre-series Wyverns with Eagle engines was confirmed, but a planned batch of 10 for the RAF was dropped, together with the F.13/44 prototypes. Subsequently, the pre-production batch was halved.

The first of six prototypes flew on 16 December 1946. However, a turboprop version with the Armstrong Siddeley Python had meanwhile been given the go-ahead and the Wyvern TF Mk 1s were assigned to various development tasks, never becoming operational. All six prototypes were flown, as were six pre-series TF Mk 1s, but the final four of the latter, although built, remained unflown as all development effort switched to the TF Mk 2.

Following the RAF’s decision to pro¬ceed no further with this project the Royal Navy opted to concentrate all future development around the Arm¬strong Siddeley Python turboprop en¬gine.

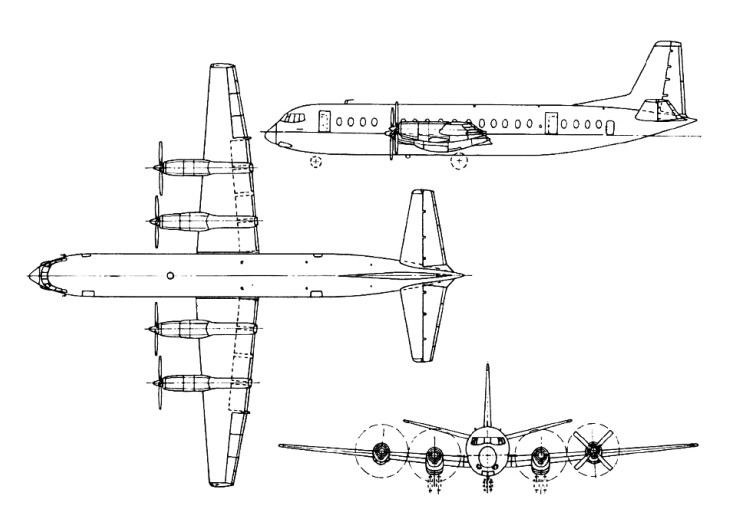

The Naval Air Staff ordered three prototypes of the (W.35) Wyvern TF Mk 2, to Specification N.12/45. Two were to be powered by the Armstrong Siddeley Python and the third by a 4500hp Rolls-Royce Clyde. In the event, the former engine was to be preferred for production aircraft. In overall configuration and armament the Wyvern TF Mk 2 closely resembled the Mk 1, although there were differences in detail, and the first flight of the Clyde-engined prototype was made on 18 January 1949, followed by the first with a Python on 22 March 1949.

Flight testing soon showed the need for modifications, noticeably to the tail unit with the progressive introduction of a larger tailplane, more fin area, dihedral on the tailplane and, eventually, finlets. Prolonged testing and development also proved necessary to achieve a satisfactory engine/propeller/throttle response system for the special demands of carrier landings, involving the two Python prototypes and most of 20 pre-series TF Mk 2s ordered in 1948 (together with a single W.38 Wyvern T Mk 3 two-seat training version).

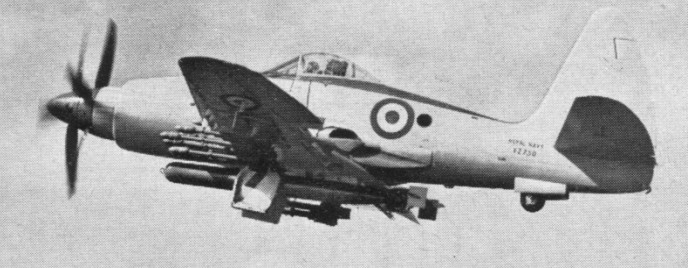

The first pre-series TF Mk 2, with a Python 2, flew on 16 February 1950, and, in June that year, became the first British turboprop aircraft to engage in carrier deck landings, aboard HMS Illustrious. Carrying a belly torpedo and 16 RPs it was a single seat strike/intruder fighter.

The final seven pre-series aircraft were completed as Wyvern S Mk 4s, this being the designation of the definitive variant with all the handling and engine modifications, and the primary mission changed to strike. The S Mk 4 was powered by a Python 3 rated at 3670hp plus 535kg residual thrust.

The principal production model was the Wyvern S.Mk 4, 94 being built in the early to mid-1950s, and these were augmented by a number of Wyvern TFMk 2 aircraft modified to Wyvern S.Mk 4 standard. Deliveries to the first FAA squadron (No 813) began during 1953. In addition, a solitary Wyvern T.Mk. 3 trainer was also completed although no production orders were forthcoming.

In September 1954, 813 embarked with their Wyverns on HMS Albion for carrier-based service in the Mediterranean. The Wyvern soon showed a worrying habit for flameout on catapult launch; the high G forces resulting in fuel starvation. A number of aircraft were lost off Albion’s bows and Lt. B. D. Macfarlane made history when he successfully ejected from under water after his aircraft had ditched on launch and been cut in two by the carrier. 813 did not return to Albion until March 1955 when the problems had been resolved.

830 Squadron was re-equipped with new aircraft before embarking in HMS Eagle on April 19, 1956. These aircraft were still designated Wyvern S.Mk4 and differed slightly in external appearance. The modifications which were visible from external inspection were:

(i) A modified cockpit canopy. This was the same shape as the previous canopy but it was a completely clear hood and did not have the metal bracing strut just aft of the pilot’s head.

(ii) The airbrake was re-designed and this can be seen from an underside view of the aircraft.

(iii) The folding wingtip facility was modded out.

Three other squadrons subsequently flew the Wyvern S Mk 4, front-line service continuing until March 1958. Operational use of the Wyvern during the Suez campaign in 1956 marked the only occasion on which British turboprop-powered aircraft saw combat use.

830 Squadron aircraft were flown ashore to Stretton and to Lee-on-Solent on January 3, 1957, and the squadron was officially disbanded from HMS Eagle in Devonport dockyard on January 5 1957.

Wyvern TF Mk 1

Max take-off weight: 9924 kg / 21879 lb

Empty weight: 7005 kg / 15443 lb

Wingspan: 13.42 m / 44 ft 0 in

Length: 11.96 m / 39 ft 3 in

Height: 4.72 m / 16 ft 6 in

Wing area: 32.98 sq.m / 354.99 sq ft

Max. speed: 734 km/h / 456 mph

Ceiling: 9785 m / 32100 ft

Range: 1908 km / 1186 miles

Wyvern S.Mk 4

Engine: one 4,110-eshp (3065-ekW) Armstrong Siddeley Python ASP3 turboprop

Maximum speed 616 km/h (383 mph) at sea level

Service ceiling 8535 m (28,000 ft)

Range 1455 km (904 miles) with auxiliary fuel

Weight empty 7080 kg (15,608 lb)

MTOW 11113 kg (24,500 lb)

Wing span 13,41 m (44 ft 0 in)

Length 12.88 m (42 ft 3 in)

Height 4.80 (15 ft9 in)

Wing area 32.98 sq.m (355 sq ft)

Armament: four 20-mm cannon

Bombload: 1361 kg (3,000 lb)