The Turbomeca Aubisque was a small turbofan engine designed and produced by Turbomeca andfirst run in 1961. Its only application was the Saab 105 military trainer aircraft as the RM9.

The engine is named after the Col d’Aubisque in the Pyrenees mountains, in line with company tradition.

The earlier Turbomeca Marboré turbojet was originally intended for the Saab 105, but when Saab needed more thrust than the Marboré produced, Turbomeca offered the Aubisque turbofan. Basically a turbofan version of the Turbomeca Bastan turboprop, the Aubisque went into the production for the Saab 105. About 300 were produced. They were in service for 30 years until replaced in the mid-90’s, by the Williams FJ44 turbofan, for the remaining Swedish Air Force Saab 105s.

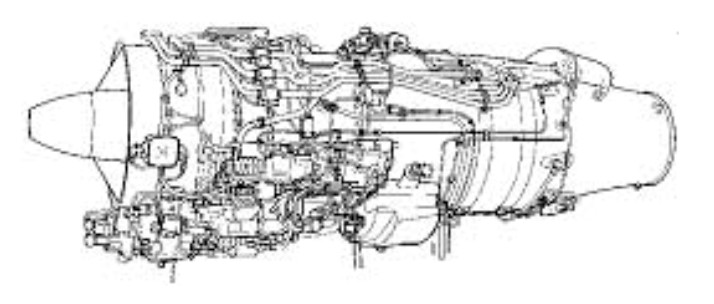

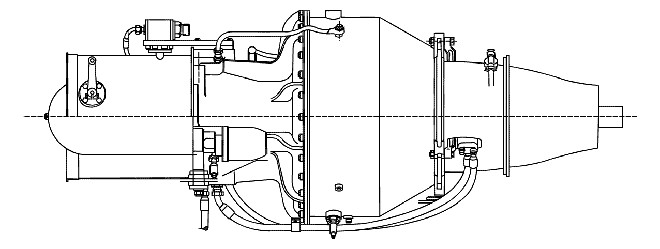

Aubisque

Type: Low-bypass turbofan

Length: 2,067 mm (81.4 in)

Diameter: 564 mm (22.2 in)

Dry weight: 243 kg (535.7 lb)

Compressor: Geared fan stage + single stage axial + single stage centrifugal

Combustors: Annular chamber

Turbine: Two stage

Maximum thrust: 6.9 kN (1,543 lbf) at 32,500 rpm

Overall pressure ratio: 6.9:1

Fuel consumption: 420 kg (925.9 lb)/hr

Thrust-to-weight ratio: 0.062 kN/kg (2.88 lbf/lb)