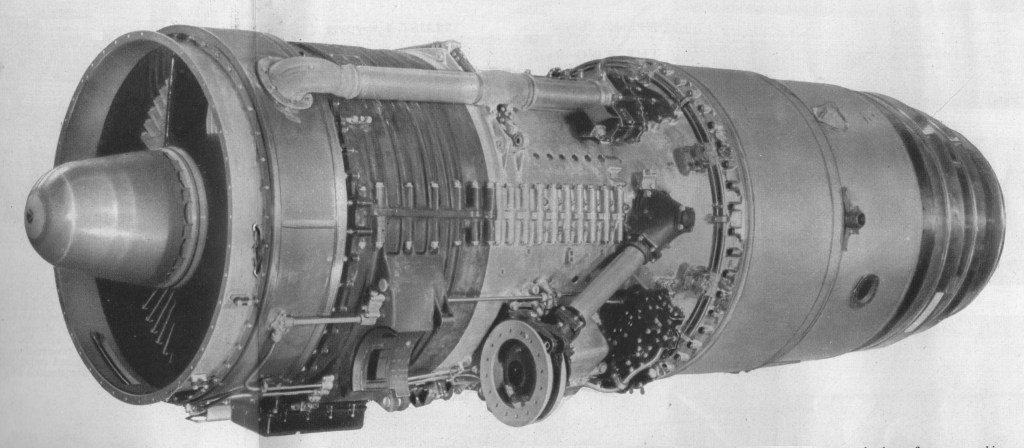

The Avon design team was headed by Cyril Lovesey, who had previously been in charge of Merlin development. The engine was intended both as an experiment in axial-flow turbojet engines, as well as (if successful) a replacement for the 5,000 lbf (22 kN) Nene. Originally known as the AJ.65 for Axial Jet, 6,500 lbf which was originally designed by Alan Arnold Griffith, the engine developed as a single-spool design with an eight, later 10 stage compressor, mass flow rate of 150 lb/s (68 kg/s) and a pressure ratio of 7.45. Development started in 1945 and the first prototypes were built in 1947.

The main series of the Avon were the 1 and 100 Series and the 200 Series. The I and 100 series have a similar axial flow compressor, while the 200 Series has a axial flow compressor with additional stages. In the 1 and 100 Series the combustion assembly consists of eight flame tubes in individual casings, but the 200 Series has flame tubes contained in an Annular casing.

The first bench testing of the Avon took place early in 1947. The first production version was running during 1949. In 1951, the first engines of the 100 and 200 Series were bench tested.

The take-off thrust of the Avon I was 6,500 lbs. Development of material allowed increased operating temperatures and when the 100 Series was introduced the thrust was 7,500 lb.

Introduction was somewhat slowed by a number of minor problems. The first Avons to fly were two Avon RA.2s in the converted Lancastrian military serial VM732, which flew from Hucknall on August 15, 1948. The prototype RA.2 weighed 2,400 lb and gave 6,000 lb thrust, while the production RA.3 was 125 lb lighter.

Initially a private venture for the company, government backing was forthcoming around the time of the first prototypes.

The engine eventually entered production in 1950, the original RA.3/Mk.101 version providing 6,500 lbf (29 kN) thrust in the English Electric Canberra B.2. Similar versions were used in the Canberra B.6, Hawker Hunter and Supermarine Swift.

The 200 Series began with 9,500 lb thrust and was soon 11,250 lb.

Uprated versions soon followed, the RA.7/Mk.114 in 1952, producing 7,350 lbf (32,700 N) in the de Havilland Comet C.2, the RA.14/Mk.201 of 9,500 lbf (42 kN) in the Vickers Valiant and the RA.26 of 10,000 lbf (44 kN) used in the Comet C.3 and Hawker Hunter F.6.

The first of the series with all-weather protection, the RA.7 had a power/weight ratio even better than that of the original production engines, notwithstanding the fact that it had been restressed to accept the loads imposed at transonic speeds. The RA.7R (the suffix “R” denotes that reheat, or afterburning, is fitted) delivers 9,500 lb static thrust at sea level, and an offshoot of the same family is the civil 500 Series, the 503 being the engine of the Comet 2.

The Avon RA.14 first ran in 1952. It has a longer compressor than its forerunners, and it also has a true annular combustion chamber in order to accept the tremendous mass flow without increasing “hoop” diameter. The R.A.14 was intended for installation in the wing (it is known that it powers the Vickers-Armstrongs Valiant B.1), and every effort has been made to reduce depth to a minimum.

Originally the Avon was made as a military engine but, in February 1952, the first flight in a civil aircraft was made. A civil counterpart is the RA.16 of 9,000 lb thrust, which was originally intended to power the Comet 3, though that aircraft had later variant, giving 10,000 lb thrust.

An Avon-powered de Havilland Comet 4 flew the first scheduled transatlantic jet service in 1958.

The modifications and improvements introduced to the Avon 200 series were considerable, resulting in a completely different engine with very little in common with the early Marks. Despite this, the name Avon was retained. Differences included a completely new combustion section, a 15 stage compressor based on that of the Armstrong-Siddeley Sapphire, as well as other improvements.

The line eventually topped out with the 12,690 lbf (56,450 N) and 16,360 lbf (72,770 N) in afterburner RA.29 Mk.301/2 (RB.146) used in later versions of the English Electric Lightning. Other aircraft to use the Avon included the de Havilland Sea Vixen, Supermarine Scimitar and Fairey Delta.

The Avon was also produced under license by Svenska Flygmotor as the RA.3/Mk.109 as the RM5, and an uprated RA.29 as the RM6 with 17,110 lbf (76,110 N). The RM5 powered the Saab Lansen, while the RM6 was the main powerplant of the SAAB Draken.

Production was also carried out in Belgium by Fabrique Nationale, including 300 Avon 113s, and a larger number of Avon 203s.

In the US, the Avon was used to power the vertical landing Ryan X-13 Vertijet aircraft (in RA.28-49 form).

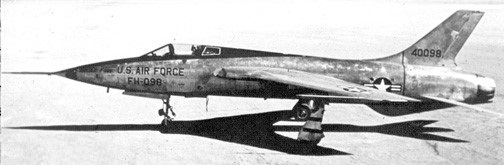

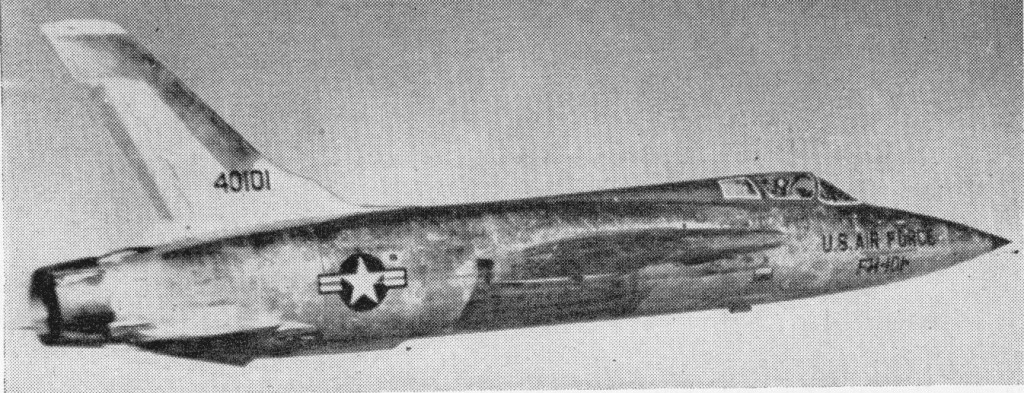

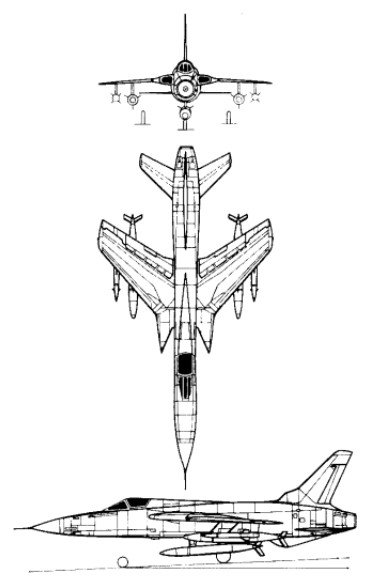

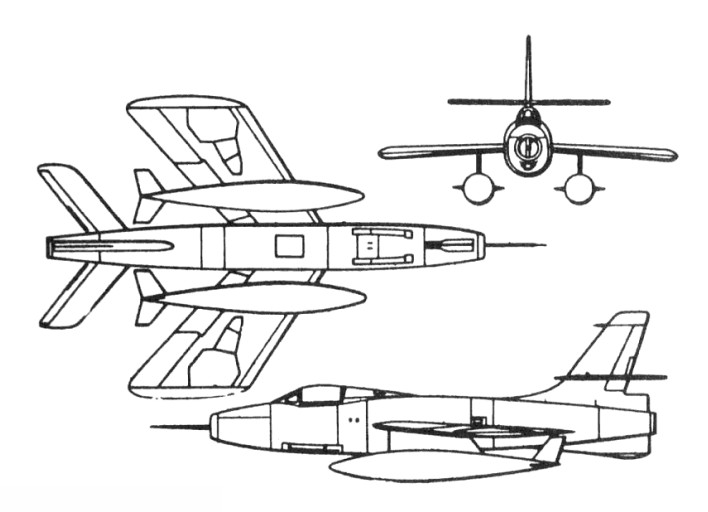

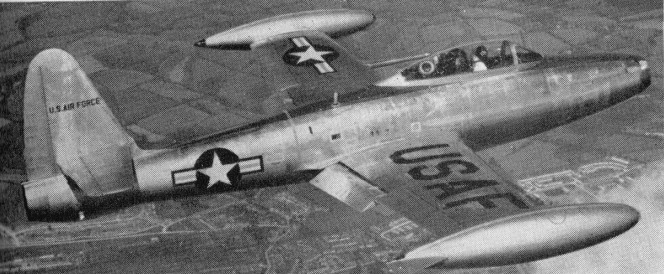

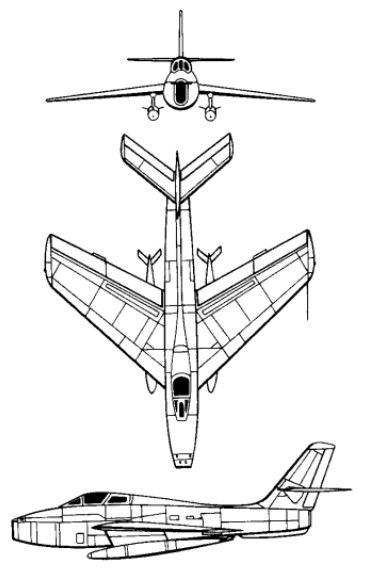

In Australia, the Avon was used by Commonwealth Aircraft Corporation to power its heavily modified variant of the F-86 Sabre, known as the CA-27 Avon-Sabre.

The Avon continued in aero engine production, mostly for the use in the Sud Aviation Caravelle and English Electric (BAC) Lightning, until 1974, by which time over 11,000 had been built. The engine garnered an impressive safety record over that time. The Avon remained in operational service with the RAF, powering the English Electric Canberra PR.9, until 23 June 2006.

The Avon 200 is an industrial gas generator that is rated at 21-22,000shp. As of 2011, 1,200 Industrial Avons have been sold, and the type has established a 60,000,000 hour class record for its class.

Variants:

AJ65

The original designation, standing for Axial Jet 6,500lbs thrust

RA.1

Prototype engines for testing and development.

RA.2

Pre-production engines for testing. 6,000 lbf (26.69 kN)

RA.3

Civil designation for the first Avon production mark – 6,500 lbf (28.91 kN).

RA.7

Civil designation for the uprated version of the Avon. – 7,350 lbf (32.69 kN).

Mk.114

Military designation for the RA.7 Avon – 7,350 lbf (32.69 kN)

RA.14

Civil designation for the uprated version of the Avon with can-annular combustion chamber and Sapphire style compressor – 9,500 lbf (42.26 kN).

RA.21

8,050 lbf (35.81 kN) Production engine developed from the RA.7.

RA.24

RA.26

Further improvements to the Avon 200 series

RA.28

Second generation variant 10,000 lbf (44.48 kN)

RA.29

Civil designation for the Mk.300 series (used by the Sud Aviation Caravelle)

RA.29/1

RA.29/3

RA.29/6

Mk.100 series

Military designation for the RA.3 Avon – 6,500 lbf (28.91 kN).

Mk.200 series

Military designation for the uprated version of the Avon with can-annular combustion chamber and Sapphire style compressor – 9,500 lbf (42.26 kN).

Mk.300 series

Developed after-burning engines for the English Electric Lightning.

RB.146 Mk.301:The ultimate Military Avon for the English Electric Lightning – 12,690 lbf (56.45 kN) dry, 16,360 lbf (72.77 kN) wet.

RB.146 Mk.302:Essntially similar to the Mk.301

Avon 504

Civilian equivalent to military Mk.200 variants.

Avon 506

Civilian equivalent to military Mk.200 variants.

Avon 522

Civilian equivalent to military Mk.200 variants.

Avon 524

Civilian equivalent to military Mk.200 variants.

Avon 524B

Civilian equivalent to military Mk.200 variants.

Avon 525

Civilian equivalent to military Mk.200 variants.

Avon 525B

Civilian equivalent to military Mk.200 variants.

Avon 527

Civilian equivalent to military Mk.200 variants.

Avon 527B

Civilian equivalent to military Mk.200 variants.

Avon 531

Civilian equivalent to military Mk.200 variants.

Avon 531B

Civilian equivalent to military Mk.200 variants.

Avon 532R

Civilian equivalent to military Mk.200 variants.

Avon 532R-B

Civilian equivalent to military Mk.200 variants.

Avon 533R

Civilian equivalent to military Mk.200 variants.

Avon 533R-11A

Civilian equivalent to military Mk.200 variants.

Svenska Flygmotor RM5

Licence production of the RA.3/Mk.109 for the Saab 32 Lansen

Svenska Flygmotor RM6

Uprated RA.29/Mk.300 for the Saab Draken

Westinghouse XJ54

Version of Avon intended to be produced/sold by Westinghouse in the US

Applications:

Military aviation:

CAC Sabre

de Havilland Sea Vixen

English Electric Canberra

English Electric Lightning

Fairey Delta 2

Hawker Hunter

Ryan X-13 Vertijet

Saab 35 Draken

Saab Lansen

Supermarine Swift

Supermarine Scimitar

Vickers Valiant

Civil aviation:

de Havilland Comet

Sud Aviation Caravelle

Other uses:

The Avon is also currently marketed as a compact, high reliability, stationary power source. As the AVON 1533, it has a maximum continuous output of 21,480 shp (16.02 MW) at 7,900 rpm and a thermal efficiency of 30%. In 1982, an Avon engine on gas pumping duty in a Canadian installation ran for 53,000 hours before requiring a major overhaul. In 1994, another industrial Avon engine ran non-stop for 476 days (11,424 hours).

As a compact electrical generator, the type EAS1 Avon based generator can generate a continuous output of 14.9 MW.

On 4 October 1983, Richard Noble’s Thrust2 vehicle, powered by a single Rolls-Royce Avon 302 jet engine, set a new land-speed record of 1,019.46 km/h (633.46 mph) at the Black Rock Desert in Nevada.

Specifications:

Avon 301R

Type: Turbojet

Length: 126 in (3,200 mm)

Diameter: 35.7 in (907 mm)

Dry weight: 2,890 lb (1,310 kg)

Compressor: 15-stage axial flow

Combustors: Cannular, 150 lb/s (68 kg/s)

Turbine: Two-stage axial flow

Fuel type: Kerosene

Maximum thrust: 12,690 lbf (56.4 kN)dry/16,360 lbf (72.8 kN) with reheat

Overall pressure ratio: 7.45:1

Specific fuel consumption: 0.932 lb/(lbf·h) or 26.4 g/(kN·s) (dry) 1.853 lb/(lbf·h) or 52.5 g/(kN·s) (wet)

Thrust-to-weight ratio: 5.66:1 (56 N/kg)