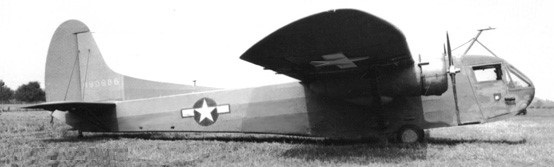

The Mohawk was a single seat twin engined high wing mono¬plane with conventional three axis control. Wing has unswept leading and trailing edges, and constant chord; two fin tail. Pitch control by elevator on tail; yaw control by fin mounted rudders; roll control by half span ailerons; control inputs through stick for pitch/roll and pedals for yaw. Wing braced from below by struts; wing profile; double surface. Undercarriage has two wheels side by side with two additional tail-wheels; steel spring suspension on tail-wheels and glass fibre suspension on main wheels. Ground steering by differential braking. Brakes on main wheels. Composite construction fuselage, totally enclosed. Engines mounted at wing height driving tractor propellers.

Warpath Aviation Mohawk Article

Conceived by Bobby Baker, the prototype of this composite construction machine made its first flight in November 1981. Using aluminium, foam and glass fibre in its construction, the Mohawk became available at the end of 1982 in the form of plans ($100) or a kit requiring 400h completion time, the kit costing $1750 without engines.

However, the company’s plans for this distinctive twin engined twin boom machine included marketing a factory built version and it is clear from the design of the single engined Mohawk X that it has been engineered with series production in mind. The Mohawk can be towed on its own undercarriage, allowing a set up and break¬down time of 20 min by two people.

The Mohawk X is similar to the Mohawk except single engined and fitted with flaps. Undercarriage has three wheels in tricycle formation with two addition¬al tailwheels. Engine mounted at wing height driving pusher propeller.

This is basically a single ¬engine version of the original Mohawk with tricycle undercarriage. The X series has a 430 Cuyuna engine driving a larger pusher prop through a 3/1 reduction unit and short extension shaft. It also incorporates a retractable nosewheel and the cockpit well set forward of the original location to compensate for the aft engine. A conventional flap arrangement is incorpo¬rated in the inboard wing panels and the wings pivot and fold back along the booms for a 5 min assembly time requiring one person. Totally re engineered internally for faster production methods, the X uses wing spars and tail booms of aluminium tubing as opposed to the built up units in the prototype Mohawk. The craft is available in two forms from the factory, first shipments to dealers being scheduled for April or May 1983. The first option is a quick build kit requiring about 60 h assembly time; Bobby Baker says this is mainly a matter of pop riveting and bolting with little glueing or glass fibre work required. This price is estimated at $5800. Alternatively, an almost ready to fly aircraft is offered, requiring only that the tail boom assembly be bolted on and minor rigging done, a total time of less than 20 h. List price of the Mohawk X in this form is estimated at $6800.

Mohawk I

Engines: 2 x Cuyuna 215R, 20 hp at 5000 rpm

Propeller diameter and pitch 33 x 10 inch, 0.84 x 0.25 m

Belt reduction, ratio 2.1/1

Max static thrust 300 lb, 136kg

Power per unit area 0.31 hp/sq.ft, 3.3 hp/sq.m

Fuel capacity 5.0 US gal, 4.2 Imp gal, 18.9 litre

Length overall 16.3 ft, 4.95 m

Height overall 6.8ft, 2.08m

Wing span 30.0ft, 9.14m

Constant chord 4.5ft, 1.37m

Dihedral 0 deg

Sweepback 0 deg

Total wing area l30 sq.ft, 12.1 sq.m

Wing aspect ratio 6.9/1

Wheel track 5.0 ft, 1.52 m

Empty weight 240 lb, 109kg

Max take off weight 550 lb, 249 kg

Payload 310 lb, 141 kg

Max wing loading 4.23 lb/sq.ft, 20.6 kg/sq.m

Max power loading 13.8 lb/hp, 6.2kg/hp

Max level speed 64 mph, 103 kph

Never exceed speed 80 mph, 129 kph

Max cruising speed 50 mph, 80 kph

Economic cruising speed 40 mph, 64 kph

Stalling speed 22 mph, 35 kph

Max climb rate at sea level 500ft/min, 2.5m/s

Take off distance 250 ft, 75m

Mohawk X

Engine: Cuyuna 430, 35hp

Propeller diameter 60 inch, 1.52 m

Reduction ratio 3.0/1

Length overall 16.3 ft, 4.95 m

Height overall 8.0ft, 2.44m

Wing span 32.0ft, 9.75m

Wheel track 5.0ft, 1.52 m

Empty weight 250 lb, 113kg

Max take off weight 550 lb, 249kg

Payload 300 lb, 136kg

Max power loading 15.7 lb/hp, 7.1kg/hp

Max level speed 64 mph, 103 kph