About 1997, Marvin Polzien decided he wanted a homebuilt blimp. There were no quick-build kits for homebuilt blimps, set of plans and a kit of materials for a homebuilt blimp. Marvin, along with friends Dennis Riley and Louie Remondino, decided to design their own. Marvin subleased part of a large military hangar on the Ardmore airport, Oklahoma, and the work began, with other volunteers pitching in.

Their first model was a cylindrical bag of aluminized plastic attached along the bottom to a welded-aluminum truss structure. A simple platform suspended from the truss provided a place for the pilot to sit (in a plastic patio chair) and a place to mount the power unit (a hot-air balloon inflator fan). About that model, Marvin says, “It was a total disaster– the material we used was no good – it leaked like a sieve. We took it out of the hanger once and I made one tethered trip around the ramp, but that was all. Then we deflated it and put it away.”

Using lessons learned from the first model, the team designed the second model. He says, “We just made it up as we went– we didn’t know what we were doing. Our learning curve was pretty wide, so we’ve got a lot of junk lying around that didn’t work.”

The first step was to select a better material for the envelope. Helium is a small molecule that can sneak its way through most materials, so low permeability was a primary requirement. They selected a .009”-thick white heat-sealable polyester plastic with good tear resistance.

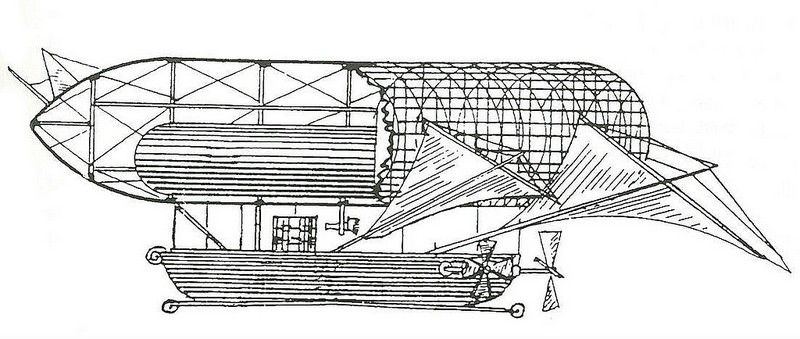

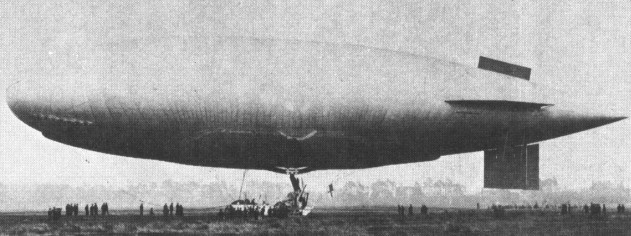

To achieve the desired buoyancy, they decided to make the envelope 82 feet long and 20 feet in diameter, tapered to form a streamlined nose and tail– an estimated 18,000 cu. ft. capacity. A two-place welded-aluminum “car” for a pilot and passenger would be supported from the bottom of the envelope, supported by a “catenary curtain” of suspension lines inside the balloon.

A 12-hp engine/propeller unit mounted on each side of the car would provide the main power. Each engine would be able to tilt up or down to vector thrust for climbing, cruising, or descending.

Pitch and yaw control would be provided by a third engine/propeller unit (24-hp) mounted on a gimbal at the extreme rear of the envelope and controlled from a control stick in the car. Fixed horizontal and vertical stabilizer panels would augment pitch and directional stability.

Inside the envelope would be two “balloonets” – smaller bags inside the large bag immediately forward and aft of the car– that could have air pumped in or out for trim control. Air would be provided from a compressor mounted on one of the engines.

A total of 13 gores of the 60” polyester would be required for the 20-ft diameter. In January 2002, the team laid out the gores on the hangar floor and cut them out. Then they began the monumental task of lapping and heat-sealing the gores together to form the envelope.

In February 2001, the envelope was fully sealed. After a preliminary filling with air (supplied ingeniously by a Shop Vac), the first filling with helium was an adventure. “We tried to fill from the middle first, but suddenly the helium all shifted to the front of the bag and up it went into the rafters! We were lucky we didn’t damage it. Now, we put sandbags across the envelope and fill from the back first. As it fills, the sandbags gradually roll toward the front,” Marvin said.

Of course, with the opportunity to fill with helium comes the necessity to empty it out now and then. But how does one keep from losing $1700 worth of helium? “Simple,” says Marvin, “We just built another storage bag bigger than the envelope and transferred it over!” But, how? “Shop Vac,” he says matter-of-factly. Marvin is a true innovator.

By March, the blimp had been taken outside for its first tethered flight. Finally, on August 3, 2002, the first free flight was accomplished. Watching video of the takeoff, Marvin said, “At that point, I didn’t know doodly about flying that blimp.”

After a short trip around the airport at about 200 feet at what appears to be about 30 mph, the video shows him approaching to land. He continued narrating, “About that time, I was asking myself how I was gonna land! I decided to rotate the engines down to pull me downward, but now I know I can just point the nose down a little to descend.”

Since then, Marvin has flown the blimp “five or six more times– I lose count.” On one flight he had an engine failure and, while trying to restart it, allowed the blimp to drift into some trees, punching a few holes in the envelope.

He has lost the lease on the big hangar and expects to be kicked out at any time. “I don’t know,” he says, “Sooner or later, I’ll have to deflate it, pack it up, and put it in my hangar.”

In December 2009 hundreds watched as a blimp piloted by 79-year-old Marvin Polzien flip flopped across the sky over Ardmore. He says he brought the blimp down near the freeway because a motor that helps steer the blimp failed. “I had three alternatives on how to land that thing. One was in the trees- that was not an option. Next one was in the median on the interstate, which is not good, and the third option which is to just take it up and let the wind blow me northwest of Ardmore,” Polzein said Thursday.

After the members of the FAA showed up wanting to see Polzien’s pilot’s license and medical certificate, which he couldn’t produce, his blimp could be grounded be for good. In order to operate an airship, it must first be certified with the FAA and its operator must have at least a private pilot’s license.

Also working against him is that fact this is not the first time he’s had to make an unscheduled landing. He crashed another home made blimp last May. That same blimp also floated away the next day and managed to make it all the way to North Texas with no one in it.