A scaled up version of the 235 hp CallAir A-9.

Production of the B-1 ceased after ownership of the design passed the North American Rockwell company as they favoured their S2R Thrush Commander.

Engine: 400 hp

Payload: 2600 lb.

A scaled up version of the 235 hp CallAir A-9.

Production of the B-1 ceased after ownership of the design passed the North American Rockwell company as they favoured their S2R Thrush Commander.

Engine: 400 hp

Payload: 2600 lb.

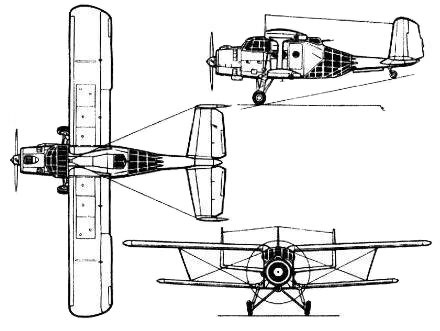

The first CallAir flew in 1941 and was designated the Model A. The last version was introduced in 1957 and was named the A-6. Throughout the years of its existence, the basic difference between any of the models was the powerplant; otherwise, the Model A-4 differed little externally from the original Model A. The CallAir was built with mixed construction: fabric-covered wooden wings and a fabric-covered steeltube fuselage.

The Model A-2, with a 125-hp Lycoming, and the Model A-3, with a 125-hp Continental, were produced during the years between 1946 and 1948.

The first production models of the A-4 appeared in 1955, and the major refinement was the addition of 25 more horsepower with the installation of a 150-hp Lycoming. All models shared the same two-to three-seat cabin and low wing with exposed struts.

Another version of the CallAir was introduced in 1956 and was basically an agricultural development of the Model A-4. Designated the A-5, it was normally flown as a single-seater with the cockpit offset to the starboard side due to the inclusion of the dust hopper.

The Model A-6 flown in 1957 was identical, apart from another jump in horsepower to a 180-hp Lycoming.

The Intermountain Manufacturing Co. developed a series of low-priced agricultural aircraft from the CallAir, and the first airplane rolled off the production line in 1963. The A-9 featured a 235-hp Lycoming; its top speed was now 130 mph, and its climb rate was now 650 fpm. The dust hopper was moved to a position in front of the cockpit.

A-1

Seats 2-3

Gross wt. 1,550 lb

Empty wt. 1,000 lb

Fuel capacity 25 USG

Engine 100-hp Lycoming

Top 115 mph

Cruise 105 mph

Stall 40 mph

Initial climb rate 500fpm

Ceiling 13,000ft

Range 260sm

A-2

Seats 2

Gross wt. 1,550lb

Empty wt. 975lb

Fuel capacity 30USG

Engine 125- hp Lycoming

Top 120 mph

Cruise 109 mph

Stall 45 mph

Initial climb rate 1,000fpm

Ceiling 17,500ft

Range 456sm

Takeoff run 426ft

Landing roll 300ft

A-3

Seats 2

Gross wt. 1,550lb

Empty wt. 975lb

Fuel capacity 30USG

Engine 125- hp Continental

Top 120 mph

Cruise 109 mph

Stall 45 mph

Initial climb rate 1,000fpm

Ceiling 17,500ft

Range 456sm

Takeoff run 426ft

Landing roll 300ft

A-4

Engine 150-hp Lycoming

Seats 2-3

A-5

Seats 1

A-6

Engine 180-hp Lycoming

A-9

Engine 235-hp Lycoming

Top speed 130 mph

Climb rate 650 fpm.

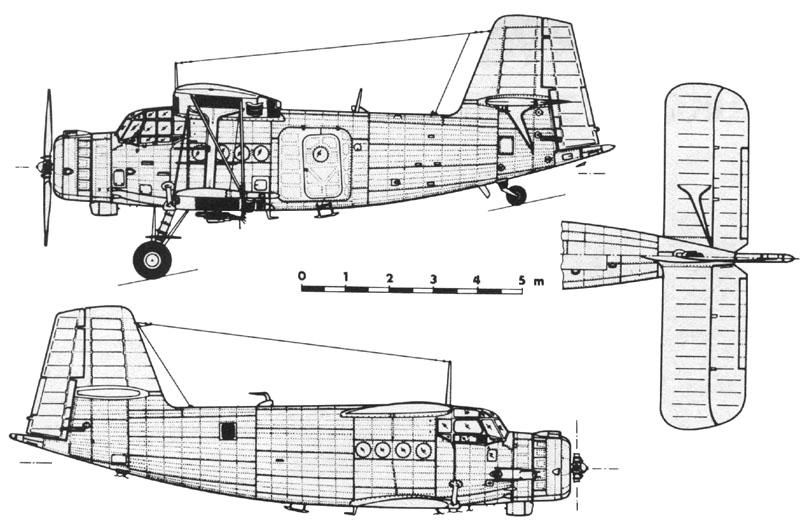

The Te Kuiti Airtruck project was a collaboration of ideas between Jack Worthington, owner of Northern Air Services, his engineer Snow Bennett and Australian aircraft designer Luigi Pellarini in early 1957.

Luigi Pellarini was familiar with the requirements of aerial topdressing operators and had worked on several designs, including the PL-7 Air Tanker.

Plans started arriving in Te Kuiti in early 1957 and construction of components began.

The idea was to build a hopper with a stub wing and attachment points for wings and the engine. The design was unusual in having no rear fuselage or conventional tailplane, the T-tail being mounted on booms attached to the wing and well away from the trail of corrosive superphosphate. To help reduce the cost, two retired Harvard trainers were bought from the Government Stores Board for component recovery.

It soon became apparent that a large number of Harvards would soon be up for tender and engines, propellers and various other items could be used in building a fleet of aircraft to replace the Cessna 180s then in service. The main wheels are from the Harvard and the separate tail units are interchangable. Pellarini then designed a larger aircraft powered by the 600hp Pratt & Whitney R 1340 radial as fitted to the Harvard. At this point the project became twin tailed.

Work began in earnest in late 1957 and by October 1959 all major work had been completed. The aircraft was then disassembled at the airport and re-assembled upside down at a workshop in the town. The wings and tail components were loaded with bags of cement as part of the static load requirements and, once this test was passed, everything was returned to the airfield at Te Kuiti for reassembly and completion.

The civil aviation authorities placed many requirements on the builders Because Pellarini had been radical in his ideas and introduced some well thought out and well-designed parts, the Civil Aviation Department came up with equally novel ideas of testing them. One of the requirements was to taxi the aircraft at speed over railway sleepers.

Throughout the construction the builders had the support of the NSW Branch of Civil Aviation in Australia, so the men from Te Kuiti knew they were on the right track.

On 27 April 1960 the PL-11 Airtruck took to the air, but just short hops as a test to see if there was any deflection in the tail booms. Again the aircraft passed the test and it finally flew as ZK-BPV on Tuesday 2 August with “Johnny” Johnstone at the controls. After a 35minute flight he returned and, with a thumbs up signal, shut the new topdresser down.

What he had flown was the first commercial aircraft to be built in New Zealand.

In 1959 Geoff Young joined the company and in October some of the staff travelled to Christchurch to dismantle and recover Harvard components.

By 1961 Pellarini had left the project and Geoff Young took over the design work in 1962. A number of components had to be redesigned and he took on this work. In the meantime, after a series of test flights at Ardmore, the Airtruck completed its first topdressing job at Te Kuiti in February 1961. Another eight hours of flight testing at Ardmore was completed in July and at the end of the year the aeroplane was taken out of service for modifications.

ZK-BPV didn’t fly again until April 1963, by which time Waitomo Aircraft had been formed. Considerable interest had been shown in the aircraft and the company started on component manufacture. What looked a bright future at last for the Airtruck came to a halt when Jack Worthington wrote off ZK-BPV at Ngapaenga on 8 October 1963. The aircraft was found not to be at fault and its unusual design probably saved Worthington’s life.

Waitorno Aircraft then set to work on a second aircraft and ZK-CKE was test flown by Jack Worthington on 9 February 1965. Other than cosmetic changes to the canopy and hopper mouth, the aircraft was the same as ZK-BPV but had to go through another series of test flights. By this stage Northern Air Services had sold out to Rural Aviation and with Geoff Young leaving at the end of 1964 the testing programme was taken on by Rex Aviation (NZ) Ltd.

ZK-CKE finally gained the Certificate of Type Approval on 17 February 1966. Leased to Rural Aviation (1963) Ltd, it was based in Te Kuiti, flown by Don Erceg, and at Taumarunui with pilot Peter Meek.

On 26 September 1966 a new company was formed, Commercial Aircraft Company (NZ) Ltd, with the idea of putting the Airtruck into production at Ardmore. An attempt to raise capital later in the year failed, mainly because of a serious downturn in wool receipts and the aerial ag industry suffering a serious slump.

In 1967 ZK-CKE was leased to Barr Bros Ltd and within a few weeks was written off at Mangakaramea, taking the life of Dick Tatham on 1 March 1967. For the second time, the accident cause was no fault of the aircraft.

It had been down to local business people of Te Kuiti – Jack Gardener who believed in the project and Jack Worthington and his pilots – who worked to fund the new aircraft. Engineers Snow Bennett, Geoff Young and later Jack Frost pushed on with the details and the hangar staff built the aircraft.

In the end both aircraft had flown a combined total of over 1000hr.

Engine: P&W R-1340-AN-1, 550 hp.

Wing span: 48 ft 0 in (16.3m)

Wing area: 369 sq.ft

Lower mainplane spanned: 11 ft 3in

Maximum height: 10 ft 10 in (3.3m)

Fuselage length: 14 ft 3in

Overall length: 25 ft 8 in (7.82m)

Height: 10 ft 10 in

Empty weight: 37001b (1678kg)

Maximum all-up takeoff weight: 72001b (3266 kg)

Max speed: 164 mph at SL

Econ cruise: 124 mph

Range: 450 miles

This company built and developed a single-engine agricultural monoplane, designated Bennett P.L.11 Airtruck, designed by Luigi Pellarini. Somewhat similar to the P.L.7 agricultural aircraft, designed by Pellarini for the Kingsford Smith Company in Australia, it flew for the first time on August 2,1960.

The S2R Series is a fixed undercarriage low-wing single-engine tailwheel configuration agricultural aircraft of all-metal construction with welded steel-tube fuselage. The hopper is located forward of the cockpit, and the aircraft is available in single or dual (tandem) cockpit configurations. The S-2R model was developed by Rockwell from the S-2D by widening the fuselage from 38” to 46” to accept a larger 400 US gallon hopper, to be able to carry a greater volume of low density materials used by Rice growers, and adding flaps.

Type Acceptance Certificate FAA Type Certificates A3SW and A4SW.

The S2R Series is a fixed undercarriage low-wing single-engine tailwheel configuration agricultural aircraft of all-metal construction with welded steel-tube fuselage. The hopper is located forward of the cockpit, and the aircraft is available in single or dual (tandem) cockpit configurations. The S-2R model was developed by Rockwell from the S-2D by widening the fuselage from 38” to 46” to accept a larger 400 US gallon hopper, to be able to carry a greater volume of low density materials used by Rice growers, and adding flaps.

Type Acceptance Certificate FAA Type Certificates A3SW and A4SW.

In 1977, the Ayres Corporation, of Albany, Georgia, purchased the Thrush Commander line and continued to build the S2R, with the same constructors serial sequence, finally ending at 2582R. Previously the type certificate had been held by Snow Aeronautical Company (up to February 18, 1970), North American Rockwell Corporation (up to April 3, 1973), and Rockwell International (up to November 28, 1977) .

A new sequence was started by Ayres with the 750 hp P & W PT6A-34AG with constructors numbers beginning with 6001, and incorporating one major change, the fitting of a 500 US gallon hopper. The 5000 sequence was used for the 100 or so 800 hp Wrights built by Rockwell.

The Turbo Thrush S2R-T34 was then developed for Ayres by installation of a PT6A engine under STC, the first such turbine application for an agricultural aircraft. This was type certificated under A3SW in the Normal Category, but the manufacturer advises virtually none have been delivered in that category. All subsequent S2R derivatives (basically different turbine engine options) were only certificated in the Restricted Category under A4SW, including several using the TPE331 family (these were popular because overhauled engines were much less expensive than a new PT6A). Some engine and propeller options for the S2R-T34, and the Dual Cockpit trainer option originally approved by STC, are only approved in the Restricted Category.

Once Ayres had taken over, one of the new versions was named the Bull Thrush, powered with a 1200 hp Wright R-1820-97 and fitted with a 500 US gallon hopper. One of the new features was a Dual Cockpit variant, being denoted by a DC at the end of the constructor’s number. From this time Ayres were to start a whole new series of constructors num¬bers, prefixed by S2R, followed by engine model fitted and then a number, in most cases, starting at -001. As example, S2R-1340-… (600 hp), S2R-1820-… (1200 hp), S2R-RS3-… (PZL R83, 595 hp) and S2R-T34-… (750 hp).

The new turbine models incorporated a wing extension from a span of 44 feet, 5 inches to 47 feet, 6 inches with a wing area of 350 square feet. The wing extensions can also be fitted to the smaller round engined versions, as well as adding an all metal tailplane. The Ayres tail version being the same outline as the tube and fabric original, and another is being offered by Weatherley.

A further development by Ayres was the Model S2R-T65, which was fitted with a larger 500 US gallon hopper and 1300 shp PT6A-65 engine. This had an increased span wing but was initially approved at the original 6000 lb. gross weight. Later an improved wing with steel spar webs was tested and the S2RHG-T65 (High Gross) version was certificated with a MCTOW of 10,500 lb. Thrush also certificated a similar high gross S2RHG-T34 version with a 550 US gallon hopper and a MCTOW of 9500 lb. However Report ER-568 stated that performance was marginal and only a few were produced. Report ER-538 states that all aircraft manufactured by Thrush since 2003 have been produced to a common fuselage and wing configuration.

Since 1991, some of the T34 aircraft have had a PT6A-41AG of 850 hp fitted and, likewise, the T15 line has had one PT6A-27 of 680hp installed. Another version available is the T45, with its own c/n sequence fitted with a PT6A-45 of 1173hp

The Type Certificate went to Ayres Corporation up to November 26, 2001, then Quality Aerospace (up to July 9, 2003), and the Thrush Aircraft Inc.

In the eighties, the US Government required a long range sprayer for anti-narcotics work. Ayres developed the T34 model and fitted it with the PT6A-65A of 1376 hp, self-sealing fuel tanks, and armour plate around the pilots seat. Up until December 1990, eight had been built with the unusual T65-1X sequence. From October 1987, Dual Cockpit versions entered the production line, beginning with T65-001DC and all going to the US Government. The first to a civil operator was 011DC, going to Gwydir Air as VH-NFH in 1990. This was re-powered by a PT6A-65AG of 1230 hp turning a five blade prop. Not only is it quieter, the length has been increased to 34 feet and the hopper has been increased to hold 625 US gallons. In 1994, the T65s were back in production, with several being delivered to South Africa.

In 1991 Ayres installed a Garrett TPE 331-6 (starting with c/ n G6-101) and up until 1994, twenty of these 750 hp versions have been delivered. Two more variants are offered, the G5 and G10, first appearing in 1993. Like the T15/34 range, they can be fitted with 400 or 500 gallon hoppers. The real advantage is the much cheaper Garrett engine.

On 14 March 2000 Ayres received the type certificate for the all new Ayres 660 Turbo Thrush. The first three aircraft are fitted with the Pratt & Whitney PT6A-60AG turbine of 1050 hp, the fourth with the 1230 hp PT6A-65AG engine, which will be available as an option.

With a work force of 62 in 2004, Thrush Aircraft principals Payne Hughes and Larry Bays have already built six new Thrush aircraft three model 660s and three model 550s, all sold to individual owners since acquiring the company in mid 2003.

The new owners have made a substantial investment, not only in purchasing the Thrush line, but also in building renovations and new machine equipment.

Thrush Aircraft has exclusively teamed with General Electric to produce the Thrush 510G powered by the GE H80 turbine engine. The H80 provides increased temperature margins to enhance hot-day takeoff performance and high-altitude cruise speeds. GE chose Thrush to launch this new engine.

The top of the range model is the Thrush 660. This aircraft was developed by the Ayres Corporation as the S2R T660 at the end of last century and went into production in 2000. Only eight aircraft were built before Ayres closed it doors at its Albany, Georgia, plant. The aircraft was designed around a 660 US gallon hop¬per and this was the first time that the airframe had been completely reworked since the inception of the Rockwell S2R 600 in 1968. The standard main undercarriage was replaced with steel spring legs, the wings were modified and an unusual dorsal fin added to the tailplane with the idea of keeping the overall in¬flight height the same as other Thrush ag planes.

With the new aircraft, the name Thrush 660 remains the same, but with a new hopper design and a new gate box for spraying, 680 US Gallons is now standard capacity. In firebombing mode, this can be increased to 750 US gallons. The vacuum bag technology in the fibreglass construction allows for a more even wall thickness, saving about 100 Ibs of weight while creating a larger interior with the same external dimensions. The new hopper has also allowed changes in the hopper gates.

The new 660 will have a longer, straight cowling, similar to the TPE331 G series, with a new, more streamlined nose bowl. The squat tailplane has been replaced with a completely new fin, which is six inches higher and thus has more surface area.

Thrush Aircraft has addressed its wing spar problems head on. The 660 centre wing beam and spar configuration has been redesigned to make the outer wing panels lighter and incorporates stronger heat treated 4340 steel spar caps, as well as a 4340 cen¬tre beam. The extra strength of the heat treated 4340 steel spar caps allow for a reduction in the number of steel doublers and inboard steel webbing, which saves weight. The 660 wing has been static tested to 14,150 lbs.

The Thrush 660 will be fitted with the PT6A 65 or the PT6A¬67. More performance enhancing features include the closing in of the rear portion of the fuselage, thus reducing air turbulence around the tail section.

The medium size version is the Thrush 550. Once marketed as the Ayres 510, the 550 has inherited the new vacuum bag technology fibreglass hopper as with the 660. The aircraft’s capacity has been increased by 49 US gallons and the top of the hopper is wider and has been redesigned to give a straight line between the propeller and the cockpit windscreen. Along with the redesign of the hopper, better fairings have been installed on the lower fuselage.

The Thrush 550 now incorporates a new 29,000 hour lower spar caps (made from 4340 heat treated steel and giving the same weight advantages as the 660), which can be retrofitted to exist¬ing Thrush aircraft eliminating all requisite ADs on existing S2Rs.

For operators requiring extra fuel, new tanks can be provided outboard of the present fuel cells. The PT6A 34AG engine will be the main provider of power but the G 10 engine can also be fitted. However, the most notable change to the Thrush 550 is the fitting of steel spring undercarriage legs.

Thrush Aircraft has exclusively teamed with General Electric to produce the Thrush 510G powered by the GE H80 turbine engine. The H80 provides increased temperature margins to enhance hot-day takeoff performance and high-altitude cruise speeds. GE chose Thrush to launch this new engine.

The Thrush 550P has wide-stance spring landing gear capable of absorbing 8800 pounds on short, rough strips and optional spring steel landing gear can be added to increase weight for take off and landings. And it brings you a 29,000 hour Wing Spar Life and a 550 gallon clear-view hopper.

The Thrush 550P has wide-stance spring landing gear capable of absorbing 8800 pounds on short, rough strips and optional spring steel landing gear can be added to increase weight for take off and landings. It has a 29,000 hour Wing Spar Life and a 550 gallon clear-view hopper.

Ayres S 2 R-T Turbo Thrush

Engine : PT 6 A 34AG, 552 shp

Length: 32.808 ft / 10.0 m

Height : 9.186 ft / 2.8 m

Wingspan : 44.291 ft / 13.5 m

Wing area : 326.149 sq.ft / 30.3 sq.m

Max take off weight : 5999.8 lb / 2721.0 kg

Weight empty : 3600.8 lb / 1633.0 kg

Max. weight carried : 2399.0 lb / 1088.0 kg

Max. speed : 138 kt / 256 km/h

Landing speed : 57 kt / 106 km/h

Cruising speed : 130 kt / 241 km/h

Initial climb rate : 1732.28 ft/min / 8.8 m/s

Wing load : 18.45 lb/sq.ft / 90.0 kg/sq.m

Range : 664 nm / 1230 km

Crew : 1

S2R-T15 Turbo Thrush

Engine: PT6A-27, 680 shp.

S2R-T34

Engine: Pratt & Whitney Canada PT6A-34, -34AG, -36, -41AG, -41, -42

Propeller: Hartzell HC-B3TN-3C or -3D / T-10282 or T-10282(N)+4

MCTOW: 6000 lb / 2721 kg

Max. No. of Seats: 1 [2 with Dual Cockpit]

S2R-T34 Turbo Thrush

Engine: 1 x P&W PT6-34AG, 750 shp.

Prop: Hartzell 2 blade, constant speed 102 in.

Seats: 1.

Length: 33 ft.

Height: 9.2 ft.

Wingspan: 44.4 ft.

Wing area: 326.6 sq.ft.

Wing aspect ratio: 6.

Max ramp wt: 6000 lbs.

Max take off wt: 6000 lbs.

Standard empty wt: 3700 lbs.

Max useful load: 2300 lbs.

Max landing wt: 6000 lbs.

Wing loading: 18.3 lbs/sq.ft.

Power loading: 8 lbs/hp.

Max useable fuel: 624 lbs.

Hopper capacity: 500 USG.

Climb rate: 1440 fpm.

Climb @ 8000 ft: 890 fpm.

Service ceiling; 25,000 ft.

Max speed: 135 kts.

Working speed: 110 kts.

Fuel flow @ working speed: 246 pph.

Endurance @ working speed: 2.3 hr.

Stalling speed clean: 60 kts.

Stall speed flaps down: 56 kts.

Turbulent air penetration speed: 109 kts.

Fixed tail-wheel undercarriage.

S2R-G10

Engine: Garrett TPE331-1, 665 hp.

S2R-T660

Engine: P&W PT6A-60AG, 1050 shp. MAUW: 12,500 lbs. Empty wt: 5150 lbs. Hopper Cap: 660 USG.

Thrush Aircraft Thrush 510P

Engine: Pratt & Whitney PT6A-34AG, 750 shp

Length: 32 feet 4 inches / 9.854 meters

Height : 9 feet 4 inches / 2.843 meters

Wing Span: 47 feet 6 inches / 14.478 meters

Wing Area: 365 square feet / 33.9 square meters

Width of Main Landing Gear: 9 feet / 2.74 meters

Fuel Capacity: 228 USG / 863 liters

Empty Weight: 4,900 lb / 2,223 kilograms

Typical Operating Weight: 10,500 lb / 4,763 kilograms

Hopper Capacity (Dry): 66 cubic feet / 1.87 cu. meters

Hopper Capacity (Liquid spray system): 510 USG / 1930 liters

Working Speeds: 90-150 mph / 145-241 kph

Stall Speed as Usually Landed: 57 mph / 92 kph

Never Exceed Speed: 159 mph / 256 kph

Sea Level Rate of Climb at 6,000 lb: 1,075 fpm / 327.7 mpm

Sea Level Rate of Climb at 10,500 lb: 666 fpm / 203 mpm

Take-Off Distance at 10,500 lb: 1,530 feet / 466 meters

Landing Distance as Usually Landed: 600 feet / 182.8 meters

Landing Distance as Usually Landed w/Reverse: 400 feet / 121.9 meters

Fuel Consumption: 45-50 USgph / 170-189 lt/hr

Cruising speed 55% power: 150 mph / 241 kph

Ferry Range at 45% power, 135 mph at 7,500 ft: 770 miles / 1,238 kilometers

Wing spar life: 29,000-hour

Thrush Aircraft Thrush 510G

Engine: General Electric H80

Length: 32 feet 4 inches / 9.854 meters

Height: 9 feet 4 inches / 2.843 meters

Wing Span: 47 feet 6 inches / 14.478 meters

Wing Area: 365 square feet / 33.9 square meters

Width of Main Landing Gear: 9 feet / 2.74 meters

Fuel Capacity: 228 USG / 863 liters

Empty Weight: 4,700 pounds / 2,132 kilograms

Typical Operating Weight: 10,500 pounds / 4,763 kilograms

Hopper Capacity (Dry): 66 cubic feet / 1.93 cubic meters

Hopper Capacity (Liquid spray system): 510 USG / 1930 liters

Working Speeds: 90-150 mph / 145-241 kph

Stall Speed as Usually Landed: 55 mph / 89 kph

Never Exceed Speed: 188 mph / 303 kph

Sea Level Rate of Climb at 6,000 lbs: 1,400 fpm / 426.7 mpm

Sea Level Rate of Climb at 10,500 lbs: 680 fpm / 207.3 mpm

Take-Off Distance at 10,500 lbs: 1,339 feet / 408 meters

Landing Distance as Usually Landed: 550 feet / 167.6 meters

Landing Distance as Usually Landed w/Reverse: 350 feet / 106.7 meters

Fuel Consumption: 45-50 USGph / 170-189 lt/hr

Cruising Speed at 55% Power: 159 mph / 256 kph

Ferry Range at 45% power 135 mph at 7,500 feet: 800 miles / 1,287 kilometers

Thrush Aircraft Thrush 550P

Engine: Pratt & Whitney PT6A-60AG

Length: 32 feet 4 inches / 9.854 meters

Height: 10 feet / 3.05 meters

Wing Span: 47 feet 6 inches / 14.478 meters

Width of Main Landing Gear: 10 feet / 3.05 meters

Fuel Capacity: 228 USG / 863 liters

Empty Weight: 5,400 pounds / 2,450 kilograms

Typical Operating Weight: 10,500 pounds / 4,763 kilograms

Hopper Capacity (Dry): 74 cubic feet / 2.10 cubic meters

Hopper Capacity (Liquid): 550 USG / 2,082 liters

Working Speeds: 90-150 mph / 45-241 kph

Stall Speed Flaps/No Flaps: 84/88 mph / 135/142 kph

VNE: 220 mph / 355 kph

Sea Level Rate of Climb at 10,500 lbs: 750 fpm / 229 mpm

Take-Off Distance at 10,500 lbs: 1,077 feet / 328 meters

Landing Distance as Usually Landed: 600 feet / 182.8 meters

Landing Distance as Usually Landed w/Reverse: 400 feet / 121.9 meters

Fuel Consumption: 65-70 gph / 246-265 lph

Cruising Speed at 55% Power: 150 mph / 241 kph

Ferry Range at 55% power 150 mph at 7,500 feet: 648 miles / 1,043 kilometers

Ferry range at 45% power: 770 sm (1,238 km)

Thrush Aircraft Thrush 710P

Engine: Pratt & Whitney PT6A-65AG

Length: 35 feet 5 inches / 10.787 meters

Height: 10 feet 4 inches / 3.14 meters

Wing Span: 54 feet / 16.46 meters

Tread Width: 10 feet 4 inches / 3.14 meters

Fuel Capacity: 228 USG / 863 liters

Empty Weight: 6,600 pounds / 2,994 kilograms

Typical Operating Weight: 14,150 pounds / 6,148 kilograms

Hopper Capacity (Dry): 95 cubic feet / 2.69 cubic meters

Hopper Capacity (Liquid}: 710 gallons / 2,687 liters

Working Speeds: 90-150 mph / 145-241 kph

Stall Speed Flaps/No Flaps: 90/94 mph / 145/151 kph

VNE: 220 mph / 355 kph

Sea Level Rate of Climb at 14,150 lbs: 850 fpm / 259 mpm

Take-Off Distance at 14,150 lbs: 1,598 feet / 487 meters

Landing Distance as Usually Landed: 600 feet / 182.8 meters

Landing Distance as Usually w/Reverse: 400 feet / 121.9 meters

Fuel Consumption: 80-85 gph / 303-322 lph

Cruising Speed at 55% Power: 150 mph / 241 kph

Ferry Range at 55% power 150 mph at 7,500 feet: 515 miles / 828 kilometers

In 1965 Rockwell-Standard acquired Snow Aeronautical, continuing to produce agricultural aircraft at Olney as Snow Commanders (as division of Aero Commander), and acquired Intermountain Manufacturing Company (IMCO) 1966. Thrush Commander was very notable specially-designed agricultural aircraft.

Working with Rockwell, Ayres commenced converting Thrush Commander 600 and 800 airframes to PT6 power before purchasing the entire production rights from Rockwell.

The entire Thrush Commander range was sold to Ayres Corp of Albany, Georgia, in November 1977 and then became known by the Ayres name.

Production continued in 1999 of various developed models as Turbo Thrush agricultural aircraft with piston and turboprop engines. The new owners will continue to manufacture the Models 600 and 800 Thrush Commanders. Fred Ayres, who developed the Turbo Thrush PT6 retrofit, was able to produce new aircraft rather than conversions. Has also developed the Loadmaster, a uniquely configured multipurpose transport with two turboprop engines driving a single propeller, intended mainly for carrying bulk and containerised freight but with passenger/troop and reconnaissance variants planned.

On 27 November 2000, the Ayres Corp filed for Chapter 11 bankruptcy protection, necessitated by the larger than expected development costs of the new Loadmaster aircraft.

single-seat agricultural aircraft, first flown 1992.

The aircraft was designed specifically for aerial topdressing in New Zealand.

The prototype, ZK-BMI, was first flown by the Auster company from Rearsby in Leicestershire on December 8, 1955; it was the first of 15 Agricolas laid down, although only seven were actually completed. Another three were later built up in New Zealand from spares.

The Agricola is a simple aeroplane, built of welded steel tube with fabric covering aft of the front spar, except for a small portion at the root of the outer wings which is metal to withstand drag loads. A 1,680 lbs capacity hopper is situated behind and below the pilot, with a trunk leading to it from the hopper mouth at the top of the cockpit. A separate 173 US gallon tank located in the starboard wing root was used on the spray version to give a quicker changeover to liquid application. The spray bars were located inside the wing, with the nozzles protruding behind the trailing edge.

New Zealand first saw the Agricola in October 1956 when the local agents, the Bristol Aeroplane Company, imported the second aircraft, ZK-BMJ, for a demonstration tour of the country. But despite an extensive showing of the aircraft there was little enthusiasm for the type, and it faced stiff competition from types such as the FU24 and Cessna 180 which were also just coming onto the market. Its tube and fabric construction, which was intended for ease of repair and maintenance in much the same way as the Tiger Moth it was designed to replace, was seen by many operators as a retrograde step, and they preferred to go the modern, all-metal way.

As well, the Agricola required a number of modifications before it was able to go into commercial use, and topdressing firms were not prepared to wait around until these were sorted out.

One aspect that makes it unique and which considerably eases the pilot workload is the hydraulically-operated hopper doors and flaps. These are run off an engine-driven pump and during the course of the day’s topdressing save the pilot a considerable amount of work by not having to continually pull levers during sowing runs and landings. Originally powered by a 240 hp Continental flat six engine, the remaining Agricolas were re-engined with the 260 hp version.

The single seat enclosed cockpit was originally entered by a door opening over the top of the cockpit, but this was replaced by a forward swinging side door to stop superphosphate entering the cockpit. There is also a side-by-side two-seat cabin just aft of the hopper trunk with a rearward facing bench seat. The rear fuselage is sealed to stop dust and superphosphate getting inside, and special filters are fitted to counter any changes in humidity and atmospheric pressure. The rear fuselage also provides another example of the Agricola’s simplicity, the nylon-coated control cables for the elevator and rudder which ran along the outside of the fabric.

Seven built.

Engine: Continental, 240 hp or 260 hp.

Span: 42 ft 00 in

Length: 28 ft 01 in

Height: 8 ft 5 in

Wing area: 254 sq.ft

Empty weight: 1920 lb

Loaded weight: 3,675 lb

Wheel track: 14 ft 4 in

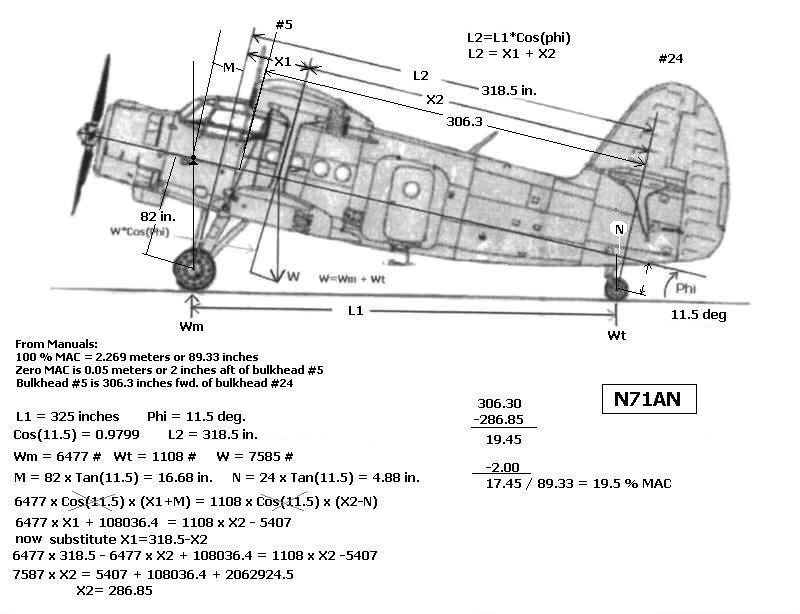

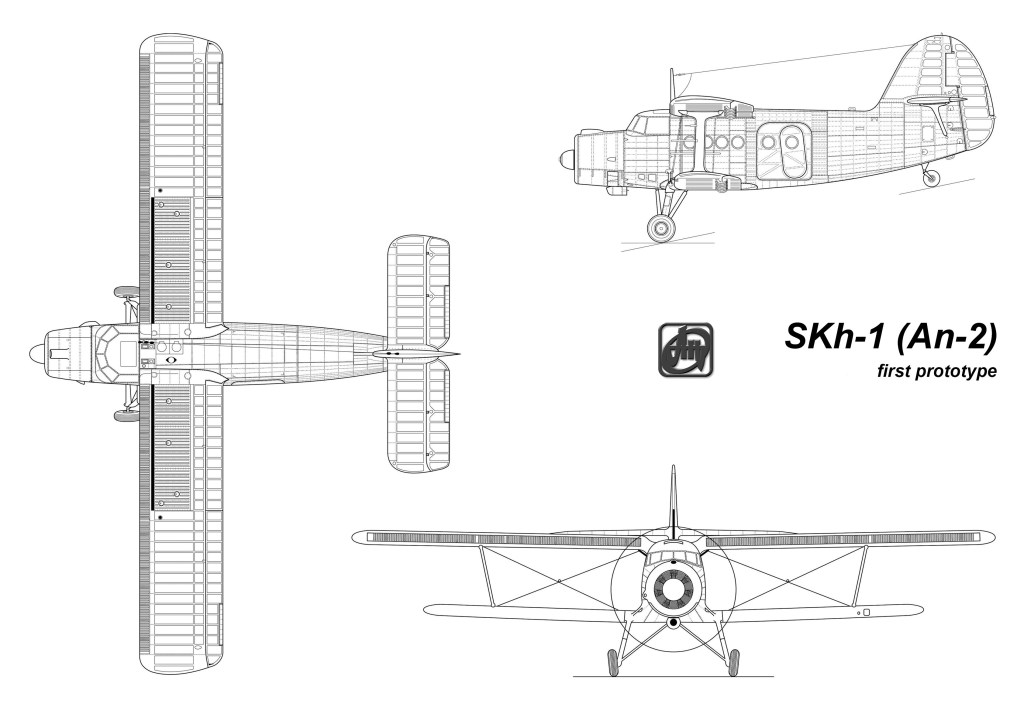

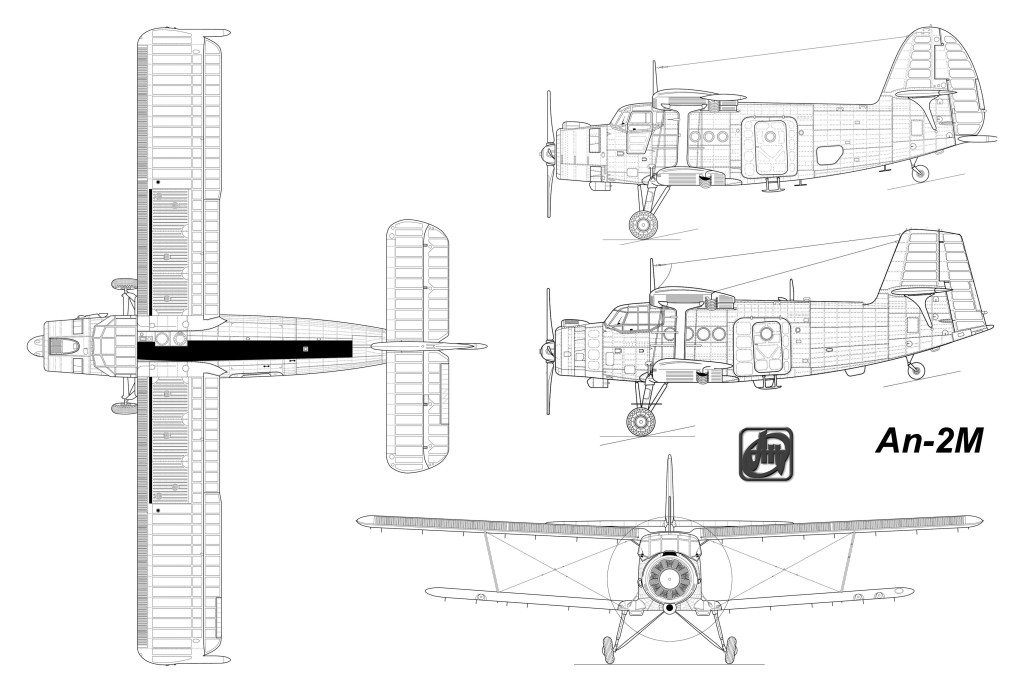

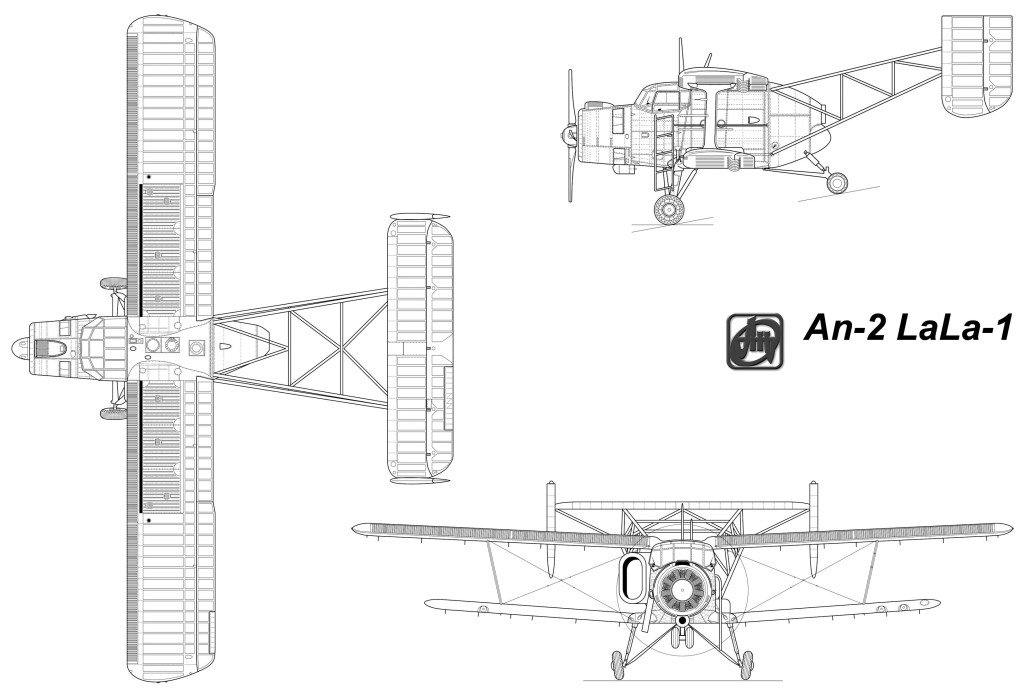

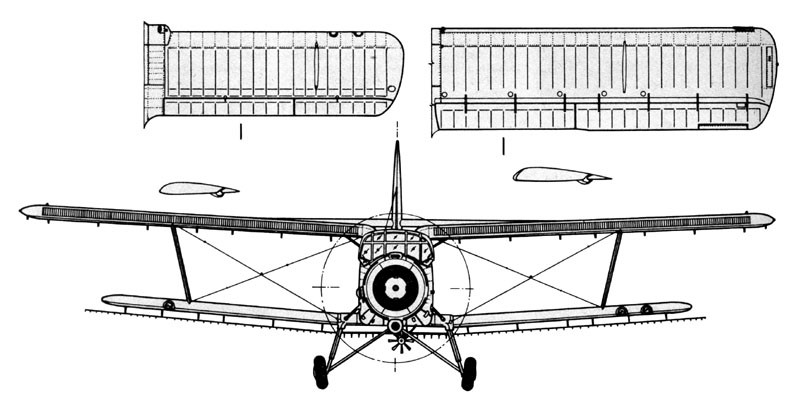

Designed originally for agricultural duties two prototypes of what became the An-2 were designated SKh-1 and the first example made its first flight on August 31, 1947. The type was developed by OKB-153 (Design Bureau 153) which was later named after Oleg Antonov. The prototypes had a 630-hp Shvetsov ASh-61, and ASh-62 respectively, radial engine with the latter being selected for production aircraft. With an all metal fuselage and fabric wings aft of the main spar, the aircraft can carry a crew of 2 plus 14 passengers. NATO code name ‘Colt’ and is designated in US DoD nomenclature as the “Type 22”.

Externally, the An-2 engine – powering a four-bladed propeller – is held in the extreme forward of the fuselage with the cockpit directly aft. The cockpit is heavily glazed and observation port windows can be seen along the fuselage sides. Wings are of an unequal span single bay biplane design, all metal construction, with fabric covering. Each wing is connected via a single large vertical strut making up a single wing bay and each wing has dihedral. The wings have full length automatic leading edge slats and ailerons droop with flap actuation to provide great STOL performance. Fuselage is of all-metal stressed skin semi-monocoque construction. The fuselage tapers slightly into the empennage which has a single large, smooth-edge vertical tail fin and stabilizers mounted to either tail fin side. Tail is a braced all metal structure with fabric covering. Wing area is 770 square feet total. Ailerons, rudder, and elevators are all manually controlled with pushrods and cables. Flaps and trim electrically operated.

The landing gear is of conventional configuration (tail wheel design) with split axle, long stroke oleo shock absorbers on the main mounts and a fully castoring and self centering tail wheel. The main landing gear legs feature wheel bogies angled inwards with each leg braced at two points along the underside of the fuselage. Brakes are pneumatically operated. Normally two pilots, but may be flown single pilot when no passengers are aboard.

The compressed air system has an 8 litre (490 cu.in) air cylinder at 49 bars (711 PSI) maintained by an engine driven AK-50M compressor and AD-50 relief valve. A pressure gauge is on pilot’s left hand console. A pressure reducer supplies 10 bars (145 PSI) for the main brakes. The Air Pressure is required for the pneumatic main wheel brakes, but can be used to charge the landing gear shock absorbing oleo-pneumatic struts when dry nitrogen is not available. A fitting is also available to fill the tires from this system. The 8 litre air cylinder can also be charged from appropriate ground support equipment.

The electrical system has a 24 VDC battery with engine driven generator to maintain charge. A Voltmeter and Ammeter are on the Instrument Panel. The 28 VDC generator requires at least 900-1000 RPM to kick in. 36 Volt 3 phase 400hz AC power, supplied by two convertors, is used to power the Russian Gyroscopic compass, Artificial Horizon and ADF.

Nine fire detectors are located throughout the engine compartment. If the Fire Warning Lamp light, the CO2 system can be activated by breaking the safety seal and pushing the button. The CO2 bottle has an electrically activated pyro-technic cartridge to release the CO2 into the collector. Portable CO2 Fire Extinguishers are normally installed in the cockpit and cabin as well.

The Oil System consists of a 125 litre (33 gal) max permitted 22 gal tank, suction pump and an external oil cooler with electrically controlled shutters. They use Aeroshell 100 Oil.

Accommodations are generally made for a crew of one pilot and cabin seating can hold an additional 12 passengers.

Almost 3600 An-2 were built at Kiev, ending in mid-1960s after limited manufacture of specialised agricultural An-2M. Production was transferred to PZL Mielec, Poland.

The An-2R developed and built by WSK-PZL in Poland was a special agricultar model. Introduced in 1964, it carried a fiberglass container for 1960 litre pesticides or 1350 kg fertilisers.

China acquired licence and has built Yunshuji-5 (Y-5) versions from 1957.China has produced many versions of the An-2 beginning with the Fong Shou-2 (“Harvester-2”). This was the first An-2 built to agricultural specifications. The Nanchang Y-5 is a transport version since taken over in production by Harbin with 727 examples delivered. Nanchang Y-5II was an agricultural form seeing production number 229. Shijiazhuang Y-5A was a light passenger model based on the An-2T and produced in 114 examples. The agricultural derivative became the Shijiazhuang Y-5B based on the An-2 SKh. The PLAAF makes use of the Shijiazhuang Y-5B(T) para-drop model. The Nanchang Y-5C is an amphibious version of the Y-5A while the Nanchang Y-5D is a bomber crew trainer. The Nanchang Y-5K became a VIP passenger transport seating five.

By 1991 over 18.000 of the different types were built in the Ukraine (5000), Poland (12000) and China (1000).

In 1994 the Polish manufacturer of the An-2, Meliec, produced a version which conformed to the US FAR 23 requirements.

The Antonov An-2 has seen combat action. It was debuted during the Korean War (1950-1953) and later in the Vietnam War – the latter by the North Vietnamese. Some An-2’s were converted from their traditional crop dusting roles to become make-shift bombers in the Croatian War of Independence (1991).

Notable operators of the An-2 have included Afghanistan, China, Cuba, East Germany (and Germany proper), Egypt, Georgia, Hungary, Iraq, Laos, Lithuania, Macedonia, North Yemen, North Korea, Poland, South Korea, Romania, Russia, Serbia, Somalia, Sudan, Syria, Turkey, Ukraine, Vietnam, Yemen and Yugoslavia.

The An-3 was originally considered as a turboprop development of An-2, but was offered as a midlife upgrade of the An-2 to have a turboprop engine and other improvements (first flown 1980).

Another organization working on a “better” An-2 is SibNIA (Siberian Aeronautical Research Institute) in Novosibirsk, Russia. In this version, the An-2MS (An-2MC in Russian) and later usually referred to as the TVS-2MS), the radial engine was replaced by an 1,100 hp Honeywell TPE331-12UHR turbine, driving a five-bladed Hartzell propeller. The first An-2MS/TVS-2MS was first flown on September 5, 2011 and by 2015 well over fifteen examples had been delivered by SibNIA and Rusaviaprom JSC, all built, from existing An-2 airframes retaining the An-2 wings and tail feathers.

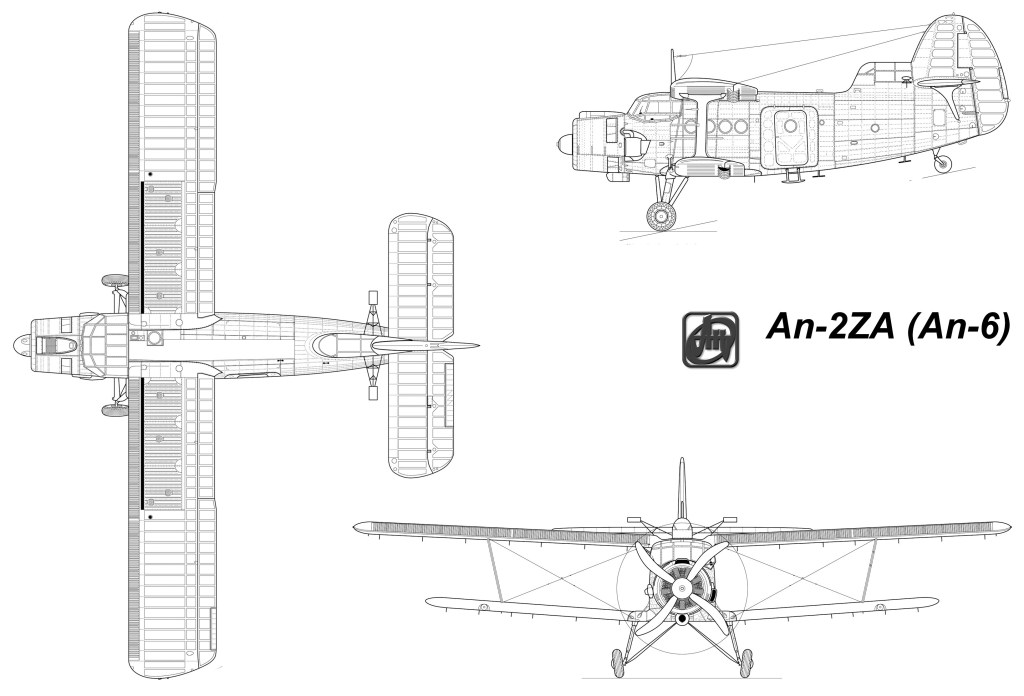

An-2 04 was modified for meteorological research by the addition of an observation cockpit in front of the fin, and a turbo-supercharger on its Ash-621R radial engine.

On 19 July 1954 it established an FAI altitude record for its class of 11,248 m (36,880 ft).

There was even a ground effect version, the An-2e WIG.

There have been various attempts to modernise the AN-2 over the years;

Antonov An-2 (Colt)

Engines: 1 x Shvetsov ASh-62IR 9-cylinder supercharged radial, 1,000 horsepower.

Length: 40.68ft (12.4m)

Wingspan: 59.71ft (18.20m)

Height: 13.45ft (4.10m)

Empty Weight: 7,275lbs (3,300kg)

Maximum Take-Off Weight: 12,125lbs (5,500kg)

Maximum Speed: 160mph (258kmh; 139kts)

Cruise: 100-110 kt.

Maximum Range: 525miles (845km)

Rate-of-Climb: 700ft/min (213m/min)

T/O roll: 220 ft.

Service Ceiling: 14,750 ft (4,500m)

Accommodation: 2 + 12

Engine: Shvetsov ASz-62 IR, 1000 hp max

Propeller: 4 blade AW-2

Wing Span: 59 ft 8 in / 18.18 m or 14.2 m / 46 ft 7 in

Length: 41 ft 9 in / 12.74 m

Height: 4.1 m / 13 ft 5 in

Total Wing Area: 256.6 sq.ft

Upper wing area: 156.2 sq.ft

Lower wing area: 100.4 sq.ft

Empty weight: 7,600 lb

Max Take Off weight: 12,125 lb / 5500.0 kg

Max Landing weight: 11,574 lb

Max fuel: 2,000 lb / 312 USG

Oil Qty: 22 Gallons Max / 13 Gallons minimum to 18 Gallons normal

Useful load max fuel: 2,525 lb

Useful load half fuel: 3500 lbs

VNE: 162 kt

VFE: 70 kt

Best Glide: 65 kt

Maximum Speed: 139kt / 160 mph / 258 km/h

Economy Cruise: 100kt / 115 mph

Minimum Speed: 49kt / 56 mph

Take-Off Speed: 43kt / 50 mph (15 degrees of flap)

Landing Speed: 46kt / 53mph (30 degrees of flap)

Stall Speed: 35-40kt (controlled descents are possible at 25kt / 30mph)

Typical SL Take-Off to 50 ft: 1600 ft

Minimum SL Take-Off Run: 560 ft

Typical SL Landing distance 50 ft: 1400 ft

Normal Range: 485nm / 900 km with 45 min. res

Max Range: 550nm / 6 hours endurance

Max SL Rate of Climb: 680 fpm

Time to 14,425 ft: 30 min

Service ceiling: 16404 ft / 5000 m

Ceiling: 14,425 ft with 1,100 lb cargo

Cross wind component: 8 kt with full flaps

Max wind speed for taxy: 20 kt

Cargo compartment: 13.5 ft long x 5 ft wide x 5.9 ft high

Cargo compartment capacity: 398.25 cu.ft

Cargo door opening: 4.5 ft wide x 5 ft high

Crew: 2 + 16

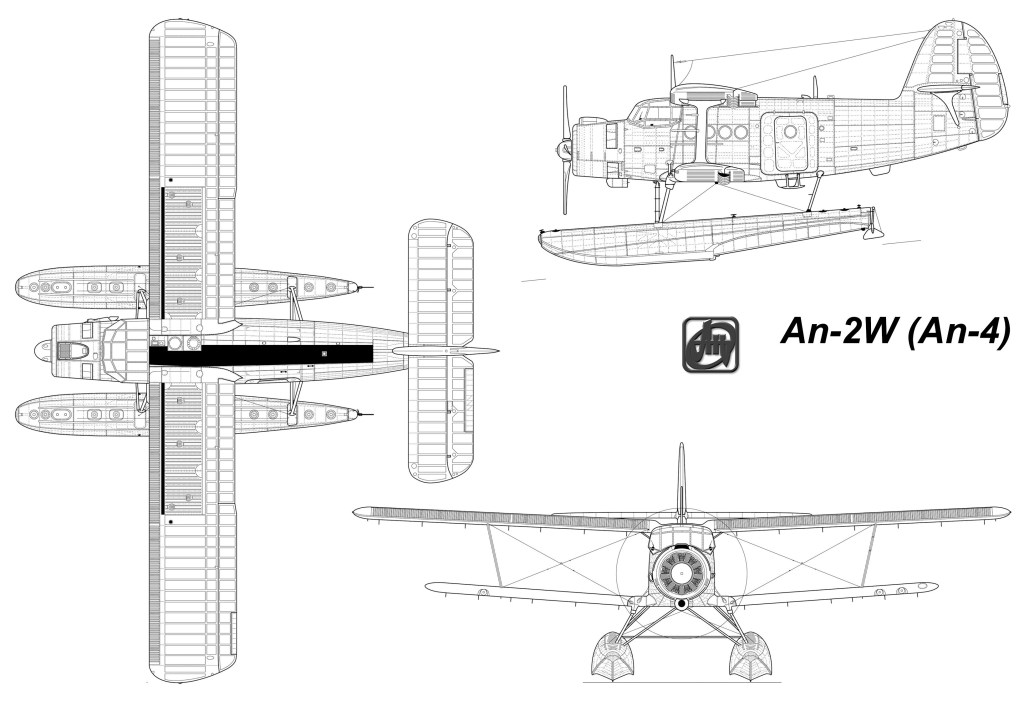

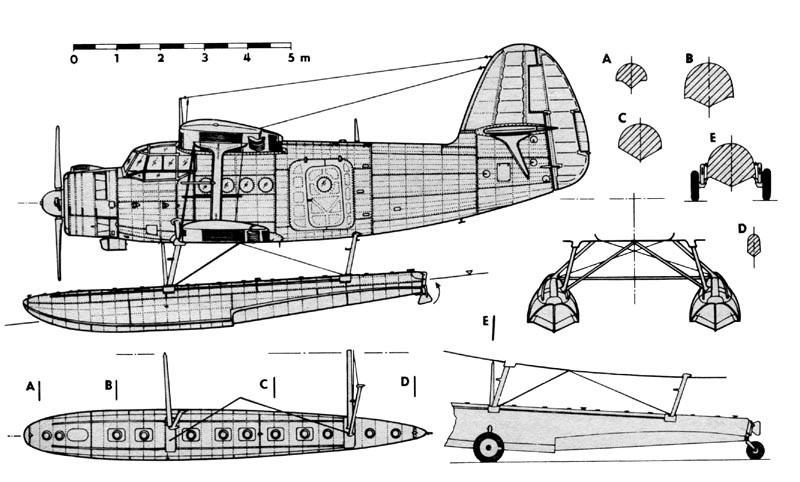

An-2V floatplane

Wingspan: 59 ft 7.5 in

Wing area: 769.6 sq.ft

Max speed: 153 mph

TO dist: 260-330 ft

Landing dist: 195-260 ft

Min water depth: 32 in

Max wave height: 20 in

Designed in Mexico as an ag aircraft, the prototype Tauro 300 first flew on 3 December 1968. An improved Tauro 350 with more powerful radial engine (350 hp) followed into production from 1977.

Tauro 300

Engine: Jacobs R-755-A2M1, 300 hp

Wing span: 37 ft 6.5 in / 11.44 m

Length: 26 ft 11.25 in / 8.21 m

Max cabin length: 3 ft 8 in / 1.12 m

Max cabin width: 2 ft 10 in / 0.86 m

Max cabin height: 4 ft 3 in / 1.295 m

Empty weight: 1973 lb / 895 kg

MTOW: 3542 lb / 1606 kg

Max cruise SL: 78 kt / 90 mph / 145 kph

Max ROC SL: 500 fpm / 152 m/min

Service ceiling: 14,000 ft / 4250 m

Range max fuel: 202 nm / 233 mi / 375 km

Seats: 1

Hopper capacity: 230 USG / 191 Imp.G / 870 lt / 1764 lb / 700 kg