The idea of an agricultural aircraft followed a meeting between George Wing, Lloyd Stearman, Tom Watson (from Aerial Agriculture in Sydney, Australia) and George Roth (of Murryair of Hawaii and later owner/producer of Eniroth). George Roth had been instrumental in the building of the Ag-1, and he was an obvious influence in the Ag-2 design by George Wing’s team.

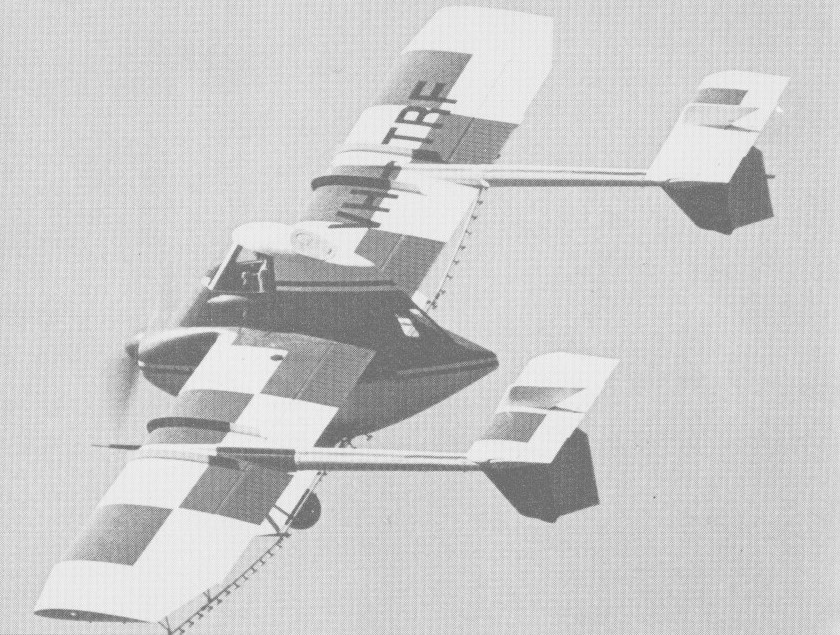

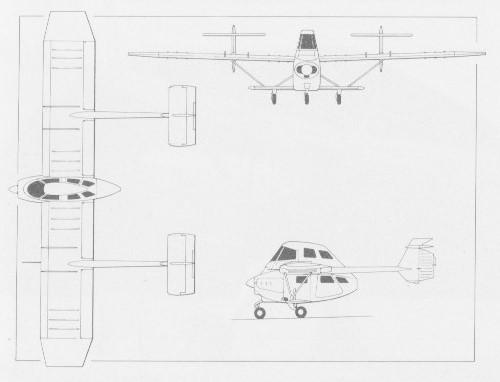

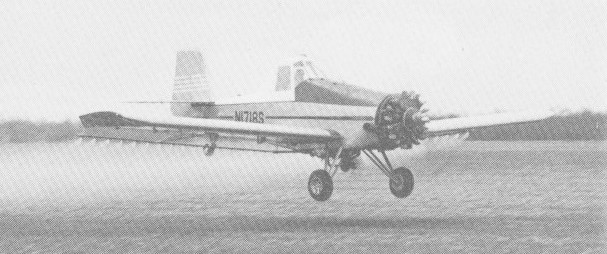

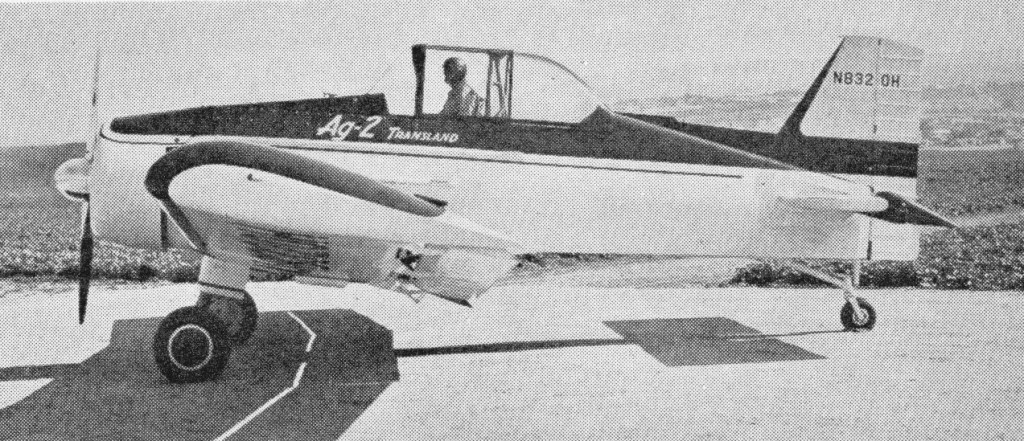

Construction of the first aircraft began in 1954 and the Transland Ag-2 made its first flight from Torrance as N8330H on 11 October 1956. At that stage, it was a single-seat aircraft powered by a 450-hp Pratt & Whitney R-985. Between the engine and the cockpit was housed an integral hopper of 53 cubic feet intended for solid materials and carrying a load of 3,000 lbs in the restricted category. The length of the cropduster was 28 ft, 5 inches and its height 9 ft. 8 inches.

The centre wing was built in two sections fastened to the fuselage either side of the hopper. Each section incorporated two 62.5 US gallon tanks which were intended as spray tanks totalling 250 US gallons. The wing was extremely thick – some eighteen inches deep – which gave high lift but also high drag. The aerofoil, a modified NACA 64021 section, had an aspect ratio of around 21%. A single flap extended under the fuselage between both sections. The outer wing panels also incorporated a 62.5 US gallon tank intended for aircraft fuel. The ailerons ran the full length of these panels with a top side lifting flap, which presumably kept a clean airflow over the wing and ailerons. Aluminium wing tips gave a wing span of 42 ft and a wing area of 321.6 sq.ft.

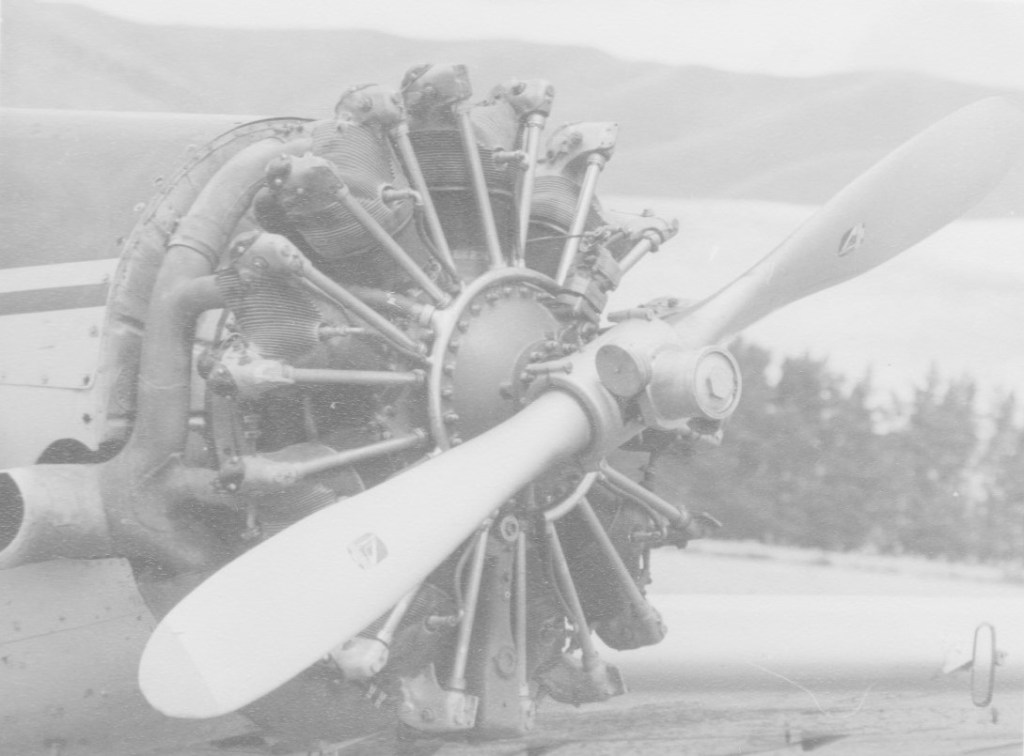

While the test flying was done on the first aircraft, a second, N8331H, was built and fitted with a 600-hp P&W R-1340. The payload was increased from 2,000 lbs to 3,000 lbs, giving an all-up weight in the agricultural category of 7,700 lbs. The empty weight of the aircraft was 3468 lbs.

N8331H first flew from Torrance in June 1958. The first aircraft was also retrofitted with an R-1340 and the rear

cockpit modified to carry a passenger. The then Civil Aero¬nautics Administration awarded Type Certificate #4A20 to Transland Aircraft for the Ag-2 on 24 June 1958.

In 1959, a third and final aircraft, N8232H, was built and operated in Panama.

The monocoque design of the Ag-2 didn’t fail, it was twenty years ahead of its time. In the 1950s and ‘60s, the Stearmans and the Naval Aircraft N3Ns were still the “big planes” of an operator’s fleet and were able to be obtained cheaply for US$5,000, as opposed to the Ag-2’s price tag of US$25,000.

With 577 hours on the clock, N8330H was sold to Charles Chalking in Uruguay in 1962. The aircraft was flown to the South American country, where it was registered CX-AYC in May 1962. Under the name of Azucarera del Litorial SA of Paysandu, it flew some 224 hours on sugar fertilizing until 31 December 1963, when it was placed in storage. The aircraft spent 28 years in storage before being sold to an operator at Triente y Tres. Flown again on 25 September 1991, the Ag-2 had clocked up another 290 hours by 23 February 1993 before it was parked up at the airfield at Triente y Tres for seven years. Around 2000 the wings were removed and stored in a shed, while the fuselage was pushed to the edge of the airfield where weeds began to incarcerate it. In April 2003 the aircraft arrived in New Zealand for restoration, with 1091.2 flying hours. At some early stage the inside of the hopper was lined with fibreglass.

Engine: Pratt & Whitney R-985, 450-hp

Seats: 1

Length: 28 ft 5 in

Height: 9 ft. 8 in

Hopper cap: 53 cubic feet

Load cap: 2,000 lbs

Spary tank cap: 250 USG

Fuel cap: 62.5 USG

Wing span: 42 ft

Wing area: 321.6 sq.ft

Engine: Pratt & Whitney R-¬1340, 600-hp

Seats: 2

Payload: 3,000 lb

MAUW: 7,700 lb

Empty wt: 3468 lb