Vertol began involvement with Tilt-Wing investigations in the 1950s with work on its company-designated Model 76 program. The research would be affirmed with a joint Army/Navy contract, signed on April 15, 1956, for a tilt wing convertiplane, defined as the VZ-2A program. The design and development contract was for $850,000.

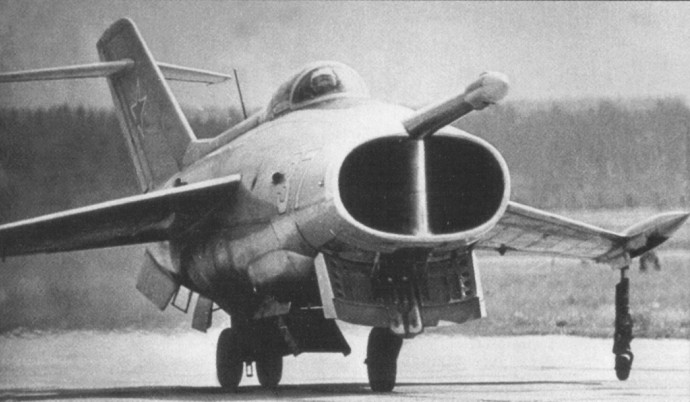

This VTOL configuration had not previously been tested in flight and the object of the programme was to build a test bed as quickly and as simply as possible. This was achieved by using available parts for several components – ¬a Bell helicopter canopy, wing actuators from the Piasecki XH 16, Piasecki HUP helicopter tail oleo struts as main undercarriage legs on the test bed and a number of parts from the Piasecki H 21. The Vertol Model 76, as the VZ 2 was known, was ready for flight in less than a year from the contract being placed.

The principal advantage of the tilt wing type of convertiplane is that it can be in most respects a conventional aircraft for cruising flight and therefore has good performance. In this respect it is similar to the tilting rotor type such as the Bell XV 3, there being some advantage in having the rotor/propeller assembly solid with the wing and tilting the whole component.

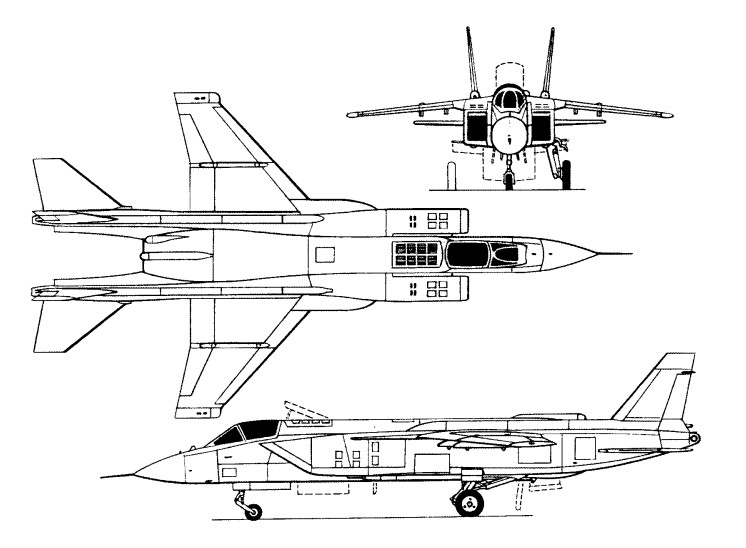

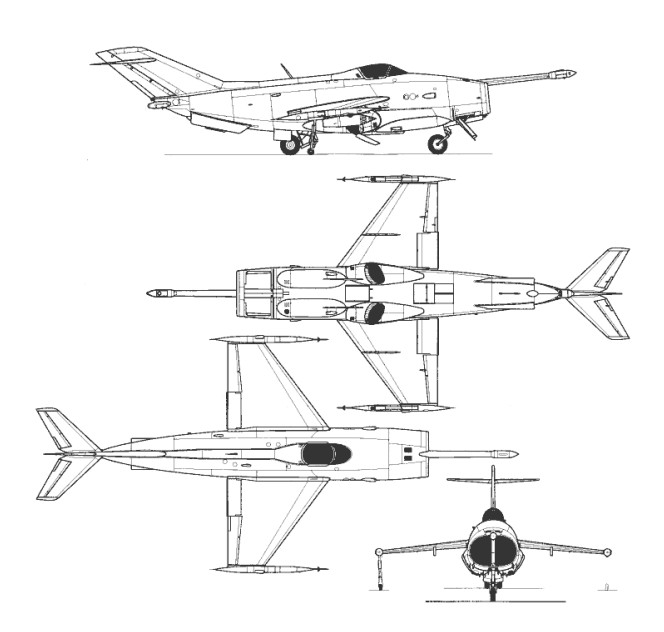

The vehicle, with much of the fuselage being of open-tubular construction, had a cockpit located far forward of the wing pivot point and featuring side-by-side seating for the two-man crew.

There were dual controls which could move control surfaces on the vertical stabilizer topped with a flat horizontal “T” configuration. The complexity of the concept was increased with the addition of a pair of ducted fans for pitch and yaw control, both being located in the tail.

A 660 horsepower Lycoming YT53-L-1 turboshaft was mounted by struts above the fuselage. The exhaust was vented outward to the left side of the rear stabilizer. Since the propellers were not attached to actual engines, the units that transferred the power from the fuselage-mounted engine resulted in considerably smaller wing units.

A portion of the turbine power was also transmitted through shafting to two ducted fans, one in the vertical and the other in the horizontal stabilizer. These fans, through a pitch-changing mechanism, were used for pitch and yaw control of the craft during hovering and transition flight.

Through a complex system which incorporated a cross shaft arrangement, the power was transferred to the pair of wing-mounted rotors which were located close to the center point of each wing. The rotors were large in diameter, at nine and one-half feet in span, and each carried three blades. The variable-pitch rotors, in addition to their primary power requirement, also provided supplemental roll control.

The craft proved to be extremely maneuverable, but was extremely slow with a maximum speed of only 215km/h. For safety purposes, the propellers were interconnected.

For aerodynamic reasons, the rear fuselage of the plane would later be skinned for smoother air flow.

Vertol test pilot Leonard La Vassar made the first flight in the VZ 2 (single example produced 56 6943) on April 13th, 1957, with the wings fixed for vertical flight. On January 7th, 1958, he made the first flight with wings horizontal and then set about ‘closing the gap’ to achieve a full transition in flight. This he did on July 15th, 1958.

Between then and September 23rd, 1959, Vertol completed 30 hours’ flying and then delivered the VZ 2 to N.A.S.A. at Langley Research Center. The first stage of N.A.S.A. testing involved another 20 hours’ flying in the next year. In this period, several modifications were introduced. A Martin Baker ejection seat was fitted changing the contours of the cockpit the rear fuselage was covered in and additional dorsal and ventral fin area was fitted.

N.A.S.A. also fitted a droop snoot leading edge to the wing. This was designed to delay the stall of the wing, which occurred initially at an incidence of 25 30 degrees, causing buffeting and control difficulties. In May 1961, Vertol was granted a new contract covering further modifications, including fitting of trailing edge flaps on the wing, which was originally flapless. With flaps, the aircraft has some characteristics of the deflected slipstream types and the stalling characteristics of the wing are further improved.

Another modification in the 1961 programme was to increase the rating of the Lycoming to 700 h.p. After testing by Vertol, the VZ 2A was returned to Langley Field. At the time the contract was placed, 448 flights had been made in the 50 hours, and 34 full and 239 partial conversions had been made.

Upon its retirement, the VZ-2A was given a place at the Smithsonian Institution.

Gallery

VZ-2A

Engine: Lycoming YT-53-L-1, 630kW / 860-shp

Rotor diameter: 2.90m

Wingspan: 7.60m

Fuselage length: 8.2m

Height: 3.15m

Take-off weight: 1443kg

Empty weight: 1128kg