In 1933 Georgi Mikhailovich Beriev was appointed head of the TsKB brigade No.5 at the Menzhinsky Factory No.39, which designed naval models. As his second he was appointed Piotr Dmitrievich Samsonov. In December 1933 Samsonov managed to obtain, independently and without Beriev ‘s authorization, the task to develop a new amphibious flying boat.

It was a development of the Beriev MBR-2 characterized by its more aerodynamic lines and its retractable landing gear towards the hull, which expanded its possibilities of use. The new model was designed to obtain a better performance model. Although it had a similar scheme, its dimensions and weight were lower and it had a cleaner design, although its construction technology did not differ greatly from the base model, and it could be built in workshops and carpentry shops with personnel with low technical qualifications. The model received the internal designation MS-2 from the TsKB and was known as the MBR-5 (Russian: Самсонов МБР-5), after the acronym for Morskoi Blizhni Razvietchik or Naval Short-Range Reconnaisser.

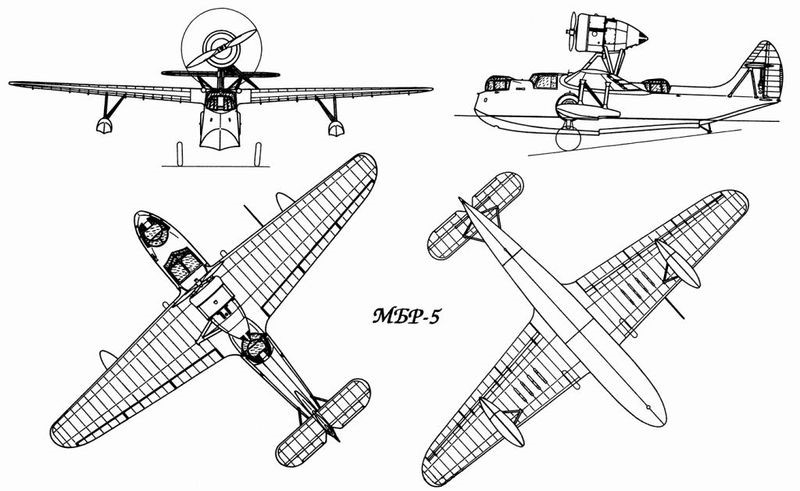

The MBR-5 was designed as an amphibious high-wing cantilever flying boat intended to serve as reconnaissance and anti-submarine combat aircraft, as well as attack bombers.

The construction was mixed with the wooden hull covered in plywood, which in turn was covered with fabric glued with waterproof lacquer. The structure generally resembled that of the MBR-2 but without the bottom keels. The longitudinal section showed the central keel and two rectangular section stringers. The cross section showed the normal frames and three reinforced master frames located where the wing spars were attached. The support points for the landing gear were also attached to the first two reinforced frames.

The entire covering of the hull was made of 3 mm thick plywood, except on the sides and bottom, where it reached 5 mm.

The wing featured a double spar structure and lacked a centerplane. The spars were of welded JMA steel tubing in a configuration similar to that used on the Ilyushin DB-3B. The wing ribs were lightweight aluminum U-shaped profiles. Welded JMA steel tubes were installed between the two spars to increase structural resistance. The wing had a MOS-27 profile and a trapezoidal shape in the plane with rounded ends. The wing covering was fabric, with the exception of the root zone, where duralumin was used. The ailerons and flaps were constructed of fabric-coated steel.

Fixed implantation stabilization floats were located in the external section of the wing. These floats, aerodynamically shaped, had redients and were made of wood with a veneer coating.

The empennage was designed as an integral part of the fuselage structure with a metallic structure and fabric covering. The horizontal planes, of variable incidence in flight, were braced by means of uprights to the keel structure and were located in the middle position at the height of the empennage, with elliptical-shaped ends. The rudder and elevator, with a metal structure and ribs formed by stamping, had trimmers and a fabric cover. The control of the rudders and surfaces was carried out by cables.

The landing gear featured original design construction. The 900 x 200 mm wheels were retracted into cavities in the sides of the hull and their axles had pneumatic suspension, withdrawing into tubes inserted into the gunwales with the help of a mechanism that pulled a rope. The tail skid, located aft of the second lead, was also retracting in flight. The extension of the gear was carried out by means of a lever in the cockpit. Once the landing gear was extended, the landing gear was fixed by means of a lock with a spring. This setting was signaled by a lamp on the instrument panel.

The MBR-5 was projected to use a Wright R-1820-F3 Cyclone engine of 712 hp at 2000 meters, which unlike the MBR-2 moved a propeller in tractor configuration. The 3 meter diameter “Hamilton Standard” propeller ensured a good air flow that guaranteed cooling. The engine was supported by three central supports and two lateral ones towards the left wing, conceived of welded steel tubes. The cowl was a NACA type with a 10-tube annular oil cooler. It was agreed that the production version would be powered by the 775 hp Soviet license-built M-25V version.

The MBR-5 crew consisted of 3: ship commander, navigator with shooter and bombardier functions, and a mechanic. The navigator was located in the forward cabin and the pilot and mechanics side by side in the flight deck. In case of need, the mechanic operated as a gunner for the dorsal station. For this he moved crawling below the midplane to the dorsal turret from which the rear hemisphere could be defended.

In the cabin there was RK-K radio equipment and a POTTE-1V camera for taking panoramic photos. The defensive points were made up of a bow position with a pair of 7.62 mm Degtiariov light machine guns for aircraft and another rear position with similar weapons. The MBR-5 could carry four FAB-50 bombs concealed under a fairing on the wing and attached to D-2 type mounts. The total bomb capacity reached 550 kg.

On the occasion of the start of serial production of the MBR-2 at the Taganrog factory, Beriev was appointed lead builder and given the task of organizing the shipbuilding or TsKB MS there. His team worked tirelessly for two months to ensure the conditions of the transfer to Taganrog. At the end of September Beriev, Samsonov and another group of builders from the No.5 brigade of the No.39 Factory moved towards the new destination.

The work of the new OKB was concentrated on the development of the modification of the MBR-2 with the M-34N engine and the introduction of the model into serial production. Beriev spent virtually all of his time ensuring these important milestones. Under these conditions he had little opportunity to pay attention to the development of the model by his replacement. Despite this, in 11 months the projection and preparation of the work plans of the MBR-5 were completed, which were approved by the main engineer of the VVS RKKA and by November 1934 the construction of the hydrocanoe began in the workshops of Factory No. .39. The transfer to Taganrog prevented the completion of construction in Moscow, so in February the MBR-5 was moved in parts to Factory No.31 in Taganrog.

On September 26, 1935, with the paint still fresh, the MBR-5 prototype left the assembly shop. It received the designation MS-2 for the new TsKB MS at that time and preparation for factory tests began.

The first flight of the prototype was made on October 3, 1935 after some tests on the behavior of the plane in water and lasted 11 minutes. The crew consisted of the test pilot of Factory no.31 A. Ulsien and the technician I. Smaglyuk.

Factory tests continued until December 24, 1935 and comprised a total of 51 flights with a total duration of 9 hours and 8 minutes.

In the results report Ulsien wrote that the runs on land and in the water were stable, but when releasing the pedals there was a marked tendency to pull to the right. The MBR-5 was extremely sensitive to rudder and aileron variations. Before raising the bow there was a certain tendency to slip. During level flight at cruising speed, a lack of stability was observed. The pilot also highlighted visibility problems in landing operations. Despite these difficulties, it was generally considered a pleasant aircraft to fly and easy to control. The MBR-5 demonstrated good manoeuvrability and an excellent rate of climb for flying boats.

A few hours before the end of 1936, the chairman of the evaluation commission and representative of the Directorate of the Red Army Air Forces (UVS RKKA) at Factory No.31, Zagainov, signed the conclusive record of the MBR-5 tests. In this record it was written:

“1 – Despite the construction and production problems, we consider that the MBR-5 with WC (Wright Cyclone) based on the results of the manufacturing tests, due to its type, its general composition, the technical flight data and the behavior in the water can be considered modern and necessary for the naval forces of the RKKA.

2 – The request for 1936 the first group of machines will be received as a field series for the operational study and definition of the neuralgic points.

3 – For the first group to be delivered in 1936 it is necessary to ask the factory to eliminate all the defects pointed out by the military representatives of the UVS RKKA in the Factory No.31 and the MLIS UVS RKKA in the state tests.“

This report filled Samsonov with pride, who was congratulated by Beriev and the collective. It seemed that the model was destined for a long service in the naval aviation of the country. Unfortunately life arranged differently.

On January 3, 1936, the same representative of the UVS RKKA at Factory No.31, Zagainov, presented the head of the 4th department of the UVS, Brigade Commander Bazenkov, with a document entitled “Record of the technical analysis carried out during the state tests of the experimental aircraft of the TsKB MS at Factory No.31: MBR-2M-34N and MBR-5”.

The minutes attached to this document indicated 159 points obtained through external and internal visual analysis, including opinions in relation to the power plants and installed equipment. It was clear that answering all these points would require a fair amount of time.

In practice, the solution to the defects took the entire winter, spring and early summer, to which a fire that partially affected the aircraft contributed. When the second stage of state tests began, the liquidation of the defects had not yet been concluded.

In the second part of the flight tests, the LIS test pilots Noman, Kosheliov, Ershov and Ryabchenko joined. The general opinion of these pilots was that the aircraft was pleasant to fly, light to control and had good manoeuvrability. As a negative aspect, it demanded too much attention during takeoff with the center of gravity advanced. This opinion practically coincided with that obtained during factory tests.

Subsequent flights demonstrated some instability during navigation. To solve this difficulty, at the beginning of 1937, work began with the assistance of personnel from department No.2 of the TsAGI (Flyingboat). It was decided to study the behavior of the flyingboat with test weights of 3,000 and 3,300 kg in the original composition and then displace the netting 40 cm and repeat the tests. These works were carried out between July 25 and until the month of September.

On October 2, 1937, during the transfer flight from Taganrog to Sevastopol for the development of state tests, after a rudder maneuver the plane plunged head-on into the water during takeoff. The strong blow ended up damaging the nose of the flyingboat and it was left with the floats up. Fortunately none of the crew was injured.

It took three days to get the flyingboat out of the bottom. It should be noted that the tapes on which the results of the flight were recorded were so damaged by seawater that it was impossible to use them. Work to restore MBR-5 was suspended.

The MBR-5 was restored for the month of September 1936, but by this time the VMF had lost interest in the model and tests were not continued. By that time, the MBR-2 with the M-34N engine had already entered series, which, both in terms of its capacity and its seaworthiness, surpassed the MBR-5. On the other hand, the TsKB MS was preparing for the first flight of the MDR-5 (TsKB MS-4), working on improvements to the KOR-1 and there was no time to devote to a failed model.

Under these conditions, Samsonov left Beriev ‘s KB and returned to Moscow, concluding the story of the MBR-5.

MBR-5

Powerplant: One 712 hp Wright R-1820-F3 Cyclone

Wingspan: 15.5m

Wing area: 32.5 m²

Length: 11.2m

Height: 4.86m

Empty weight: 2060 kg

Maximum takeoff weight: 3260 kg

Total load capacity: 950 kg

Wing loading: 95.5 kg/m²

Power load: 4.4 kg/hp

Maximum speed at sea level: 256 km/h

Maximum speed at altitude: 306 km/h

Cruising speed: 220 km/h

Landing speed: 110 km/h

Time to 3000 m: 8 min

Practical range: 750 km

Practical ceiling: 7500 m

Armament: 4 x 7.62 mm Degtiariov machine guns

Bombload: 550 kg