Originally designed by Outboard Marine Corporation (OMC) between 1974 and 1984, it was rumored that they spent hundreds of millions of dollars to develop this engine. OMC originally had a 530cc single rotor air cooled engine that was installed in 15,000 snowmobiles made by Johnson and Evinrude in the early 1970s.

OMC spent a small fortune developing a rotary engine. At one point they had a team of over 40 engineers working to develop the engine but about the time they were about to start production on the engine the snowmobile industry fell on hard times and the project was put on the back burners.

RotaMax purchased the design, and has reintroduced it to the market. RotaMax was marketing the engine for Recreational, OEM, Transportation, Aviation, Marine, Aftermarket and Xtreme applications, which is where the name RotaMax originates from.

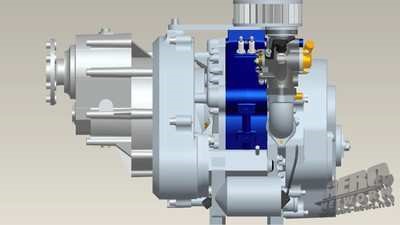

The unit was available in two configurations a 650cc single rotor of 75 hp which weighs 90 lbs and a 1300cc twin rotor unit putting out 150 hp and weighing 140 lbs. The RotaMax engine is all aluminum.

The ASTM LSA engines have a dual ignition system, and are fuel injected. The unit uses a spur gear reduction drive system with a 1.95 to 1 reduction ratio.

At Airventure Bill met Eric Barger of RotaMax Rotary Engines of Ohio, and he was so impressed with company and engine that he decided to use it in the Vampire. Since Airventure he has put over 40 hours of trouble free flying on the engine.

At Sebring he had the engine in his booth on static display. He also demonstrated the engine running in the Vampire. According to Bill the engine is very smooth, sounds a lot like a turbine, and is considerably more powerful than the Rotax 912 S.

Eric Barger President of RotaMax was at Sun N Fun showing a number of aircraft installations that are currently using the RotaMax rotary engine. These included Higher Class Aviation and their Hornet, Sadler Aircraft and the Sadler Vampire.

The RotaMax single rotor 650 cc, 65 HP engine will use between 3 and 4 gallons of fuel an hour, while the twin cylinder 1300 cc engine uses 4 to 6 gallons per hour, again this will vary with the type of application the engine is being used in.

All of the RotaMax aircraft engines are equipped with dual ignition systems. The single cylinder engine was only available in a carbureted version, with the twin cylinder 1300 cc engine being fuel injected.

The RotaMax 1300 cc twin rotor engine has a top RPM of 4750, with cruise RPM being 4250.

A unique feature of the RotaMax engine is that it uses a “lost oil system.” Regular 30 weight oil is injected into the engine, and is burned off in the combustion cycle. This means you do not have an oil pan, you do not require any oil changes, no oil filter, and no waste oil to dispose of.

The RotaMax engines came with a standard charging system of 32 amps but an optional unit of 45 amps is available. The engine uses an oil bath spur gear reduction drive, with ratios from 1.9 to 2.7 available. RotaMax was developing belt drive systems to fit various applications. A number of exhaust systems were being developed, all of the systems are made from stainless steel due to the higher exhaust heat that the engine produces.