The 23 of January of 1940 the Commissariat of Aviation Industry created the Directorate for creating landing gliders. In the autumn of that year, in an extraordinary meeting, with the presence of Stalin, the decision was made to launch a competition for the development of airplanes of this type and their series production. The best would be mass-produced and used successfully in operations during the Great Patriotic War.

Nikolai Polikarpov had no experience in glider design, so he did not participate in the competition. Despite this, at the beginning of June 1941 its construction bureau, unexpectedly for many, presented a project for a landing glider. The production of gliders was carried out not in aviation factories, but in carpentry and furniture factories.

The Polikarpov glider was designed as an aircraft to support penetration units. After analyzing the losses of the Germans during the landing operations, the Soviet aircraft manufacturer came to the conclusion that it was possible to reduce them by using well-protected and armed means of landing. To achieve this objective, he designed a glider from which the landing troops, before launching themselves, could direct fire against enemy positions, using their light weapons. The protection of the device was obtained through the use of removable armoured plates, which once landed the glider allowed to create a defensive barrier for the soldiers.

The new glider was named BDP (Russian: Поликарпов БДП), after Boyevoi Disantni Planior or Military Landing Glider.

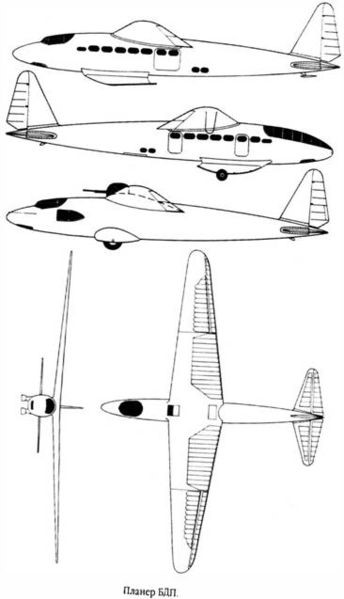

The BDP landing glider was desiigned as a high-wing monoplane with a 20-meter wingspan and an aerodynamically designed fuselage. The entire construction was made of wood.

Designers put special emphasis on making an airplane cheap and easy to produce. Due to its dimensions, the BDP was capable of transporting 16 soldiers with their equipment and its towing had to be carried out by Túpolev SB or Ilyushin DB-3 bombers. The fuselage was entirely made of wood. The pilot had an emergency cover with a structure also in wood. To improve visibility during landing, the lower part of the cab was glazed.

The landing troops sat on benches located on the sides of the fuselage, forming part of the structure. Between the two rows of benches there was a 600mm corridor. The exit of personnel and cargo was carried out through two 900 x 950 mm doors, one located in the front region on the right and the other in the rear on the left. In the first BDP copy there were two small doors on the right and two on the left.

In the lower part of the fuselage, behind the cargo area, a hatch was prepared to parachute from the glider.

The wing of the BDP was made of wood and had a single spar. The coating of the leading edge and the force points was done with plywood. The rest of the wing was covered with fabric. The wing profile used was the NACA 230. In order to reduce the landing speed in the section between the ailerons and the fuselage, Shrenk-type flaps were installed.

In the area of the leading and trailing edges of the wing, special hatches were located to allow firing with light weapons, covering the upper hemisphere. To defend the tail a section of the upper rear fuselage could be raised and become a firing point for the gunner.

The tail was monoplane and cantilever, constructed of wood covered with plywood and fabric.

The landing gear consisted of two ash skis placed on leaf springs to absorb the impact. The junction of the skis and the fuselage was covered by fabric covered fairings. For landing the BDP used a 400 x 150 mm four-wheel detachable wheelbarrow.

The glider did not have its own weapons, but did have attachment points for seven DP-type infantry machine guns. Two machine guns could be installed to defend the upper hemisphere, one in the lower hatch and two on the sides.

Inside the fuselage were 12 5.5 mm armored plates with dimensions of 480 x 550 mm. The pilot had armor on the back of the seat. All this protection added 127 kg to the weight of the glider.

The development of the BDP project was carried out by Polikarpov and his collective during the month of June 1941.

The project was approved by the NKAP management and it was decided to carry out the construction of the prototype at Factory No.51.

By the end of the summer of 1941 the glider was finished and ready for flight tests. The first flights were carried out in September and took place from the LII airfield in the Moscow suburbs. As a tug, an SB bomber with M-103 engines was used. The glider was piloted by VP Fyodorov.

Only 14 flights were made, which were interrupted on October 14 due to the advance of the Germans and the beginning of the evacuation.

As a result of the tests, defined as inconclusive, it was concluded that the BDP was stable in flight and that it could be maintained with free controls. The effectiveness of the rudders was acceptable, both during flight and on landing. The piloting technique was simple and did not demand a great qualification from its pilot, which ensured its control by pilots who had flown training gliders.

The negative aspects were the lack of structural strength at various points on the wing and fuselage. This caused that during the tests the flight weight was limited to only 2200 kg and the speed up to 220 km / h (the glider having been calculated for 3200 kg and 320 km / h respectively). The pilot pointed out that the curved glass in the windshield distorted the vision and proposed to replace it with a normal one made of straight pieces. When the aerodynamic brakes were extended, there was creaking in the tail area.

It was recommended to work on solving these problems and then present the model for series production. In relation to this process, there were no difficulties, since the construction could be carried out in carpentry with basic equipment. TsAGI specialists warned that the production cost of the Polikarpov model exceeded that of other similar gliders.

This first specimen was evacuated by air in October 1941 to the west. Curiously, during the flight of this unknown aircraft towed by an SB bomber, a group of fighters from Moscow’s anti-aircraft forces (PVO) went out to intercept, forcing the glider to land near Kashira. The glider was looted by the local inhabitants and in that condition it was returned to Moscow shortly thereafter.

The second specimen, called BDP-2, was built in Novosibirsk, where Factory No. 51 in Moscow and the KB in Polikarpov were evacuated.

The glider was delivered for testing to the LII affiliate on February 6, 1942 and flown by II Shelest.

The BDP-2 presented a reinforced construction in relation to the original model, which brought with it a certain increase in weight. Externally it was also something different. The pilot’s windshield featured flat glass pieces and various elements were simplified. The trailing edge of the height and steering rudders was made by means of a steel cable as was the style in the first Soviet aircraft.

The tests of the BDP-2 with ski landing gear lasted until March 14, 1942. During this time several attempts were made to lessen the problem of tail creaking. The results improved after drilling a series of holes in the aerodynamic brakes, thus reducing the turbulence of the airflow.

The test conclusions again emphasized the simplicity of the piloting, the high payload capacity, good manoeuvrability and stability in different centering regimes. Serial production of the model was recommended.

Almost in parallel with the flight tests, the search began for a possible production base to develop series production. After reviewing various factories and companies in the region near Novosibirsk, it was decided to select the Siberian Military Region Workshops. These facilities had previously functioned as auxiliary production capacity for Factory No.153, dedicated to the manufacture of skis.

The first figures showed a number of 100 gliders with a unit cost of 41,125 rubles.

While negotiations were taking place, a new production site was defined. It was the Stalingrad Factory No. 490. In the middle of the summer of 1942 the plans and all the technical documentation were transferred there from Novosibirsk. Soon the military situation changed and the arrival of the Germans in Stalingrad thwarted production plans.

Along with the inability to produce in Stalingrad the opinion of the VVS was a lack of need to produce the BDP. The course of the war had shown little chance of success and there were already produced successful models A-7 of Antonov and G-11 of Gribovski.

In July 1942 the BDP-2 was destined to serve as a transport in the direction of the Moscow – Irkutsk air force. Several flights were carried out towed by a PS-40 (postal Ant-40) on the Novosibirsk – Omsk – Sverdlovsk route and vice versa. This route was also covered by several Antonov A-7s . The results of these experimental flights were impressive and it was proposed to build several examples of transport gliders for civil use with Aeroflot.

In 1943, at Factory No.51, the assembly of 10 copies of the BDP began. It is known that until the end of the year only two copies had been delivered. A third and fourth specimens were 98% complete, the fifth at 80%, the sixth at 28%, and the seventh only at 10%. No evidence has been found after that date.

Polikarpov, in an attempt to achieve full autonomy for the BDP, decided to develop a motorized model that was named MP. A prototype was successfully built and flown, but it was not mass-produced either.

Polikarpov BDP

Wingspan: 20.00 m

Length: 13.60 m

Wing area: 44.72 m²

Empty weight: 1470 kg

Normal weight: 3408 kg

Crew: 1

Payload Capacity: 16 Soldiers Equipped