The history of the first Soviet fighters begins with the decision to create a construction bureau at GAZ No.1 in Moscow (formerly known as Duks and created by Yulius Alexandrovich Meller in 1893) in January 1923. Initially the leadership of this bureau it was assigned to N. N. Polikarpov, but as early as February D. P. Grigorovich, who had recently returned to Moscow, was appointed to this post.

At the end of 1923 Grigorovich would organize his own construction group made up of renowned specialists such as AN Sidielnikov, VL Korvin-Kerber, AA Krylov, VV Kalinin and VL Moisienko and an experimental construction workshop. His main task was to achieve an improved development of the I-1 fighter capable of showing more satisfactory performance.

The projection of the new fighter, called Grigorovich I-2 (Russian: Григорович И-2), began on January 1, 1924. It is noteworthy that until 1926 this model was known indistinctly as I-2 or I-7. The denomination I-7 would finally disappear to leave only that of I-2, with which it is found in the documentation of the period.

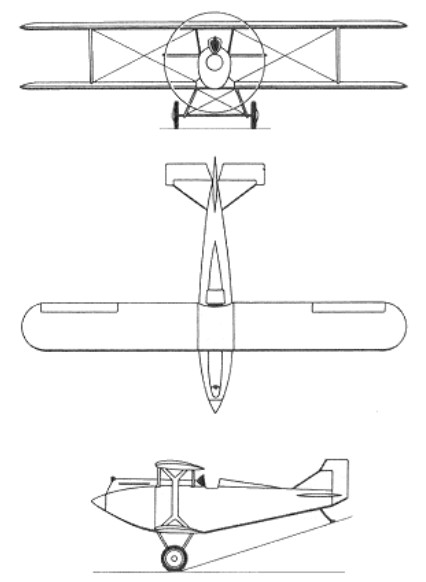

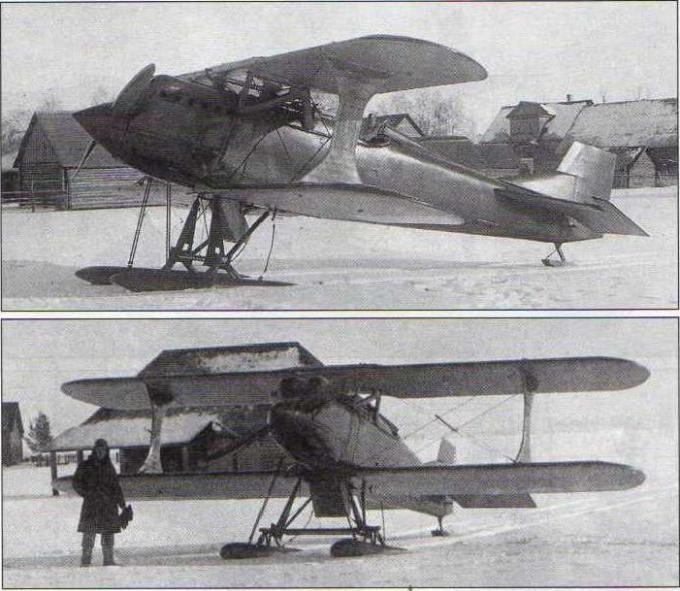

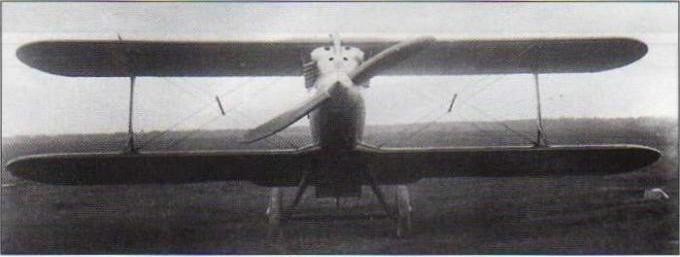

Grigorovich’s new fighter was designed as a single-engine, single-seat biplane of conventional configuration, built of wood and fabric. It basically repeated the construction and power plant of the previous I-1, but incorporated a new fuselage, modified interplane pillars and changes in the shape of the hood to improve visibility.

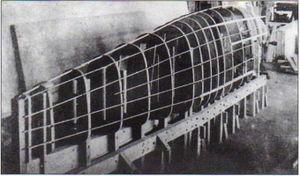

The fuselage had an oval section and in the bow section it had a metal structure to which the power plant was fixed. Starting from the pilot’s cabin, the fuselage became a wooden construction with a monocoque structure and sheet metal covering, glued around the structure.

The biplane wingbox featured wings of equal span, without offset. The upper plane was fixed by means of an N-type structure built with steel tubes and the planes had I-shaped supports made of duralumin and fully faired. Wing stiffness ended up being achieved by simple tension cables.

The wing was built of wood and featured a double spar structure. The ailerons were located only on the lower wing, protruding slightly outside the trailing edge. The wing skin was made of plywood. The trailing edge was made with steel cables and in the plan view it was shown as the wave trace.

Both the tail and the wings were built on an aluminum frame covered in fabric.

The landing gear had a pyramidal structure quite characteristic for the time. The supports were made of steel tubes and the amortization was achieved by means of 16 mm diameter rubber tensioners. For winter operations the train of wheels could be replaced by another with skis.

The I-2 used the M-5 engine with 12 cylinders in V and 420 hp of power (copy under license of the North American Liberty L-12 engine).

In front of the cockpit, in the central section of the fuselage, the main fuel tank with a capacity of 200 liters was located. Another 96-liter fuel tank was located in the center plane, in the center of which was a fuel-in-tank sensor using a float.

The I-2’s armament comprised two 7.62mm Vickers or PV-1 machine guns with 500 rounds each. On most I-2s the machine guns protruded from the fuselage.

The construction of the I-2 began on February 1, 1924 and the subsequent events are not very clear if we discount the scandal of late 1924 and early 1925, when during the tests of the I-2 and IL-400 the subject came up about its authorship. It was about the attempt of the GAZ No.1 specialists to “collectivize” these creations, eliminating not only the authorship and creative work of their designers, but also the responsibility for development. Polikarpov and the group of specialists, who worked on the IL-400, ended up giving in and authorized the transfer of all the rights to their creation to GAZ No.1, but Grigorovich was intransigent and the matter went to court.

During the hearing, the constructor declared: “The I-1 and I-2 aircraft, from their primary conception to the smallest details, have been developed by me with the participation of my close collaborators, the engineers AN Sidielnikov and VL Korvin-Kerber, with the support of drawers Shvarts, Nikitin and others on a smaller scale. The engineer VV Kalinin developed the diagrams for the fuel pump and the pipes, but they were not used in the end. Engineer AA Krylov worked out the control system from my sketches.”

Grigorovich’s opponents, the engineers Sutugin, Uspasski and Shirokov told Grigorovich that during the development process he had left for Leningrad, that using his position as director of the GAZ No.1 he pushed aside a group of specialists, who his direction in the projection and construction of airplanes was superficial and in terms of the originality of his designs the new fighters lacked it as they were very conventional schemes.

Despite this, the director did not give in and, determined not to give up his leadership, continued the discussion showing the first sketches, calculations and drafts of the I-1 and I-2 fighters. Finally, taking into account his authority and experiences, but above all his stubbornness, it was decided to keep Grigorovich alone as the author of these designs.

Construction of the I-2 was proceeding smoothly, and the prototype was found ready by September 6, 1924. After the review by a committee of the Scientific Committee of the VVS Directorate (UVVS) and several ground tests of the engine’s work, it was decided to allow flight tests. On November 4, pilot AI Zhukov took the aircraft into the air for the first time.

The results of the first flight were considered satisfactory. Zhukov noted the ease of control, the short take-off run, and the ease of landing.

Subsequent flights, aimed at establishing the maximum speed and the flight ceiling, resulted in the need to make some adjustments to the control surfaces, the controls and the power plant. Contrary to expectations, Alexandr Zhukov noted that control of the plane had worsened. In low-speed flight it was not very stable and when accelerating it tended to dive. After the sixth flight Zhukov decided not to continue the flights. The cause would soon be found: the tail skid in his operation pressed the flight controls.

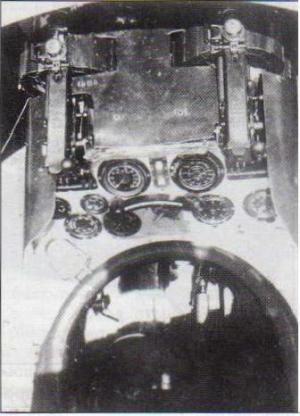

On November 19, 1924, the I-2 was flown by MM Gromov and VN Fillipov, who found nothing strange in the behavior of the aircraft, but criticized the cabin for being cramped and uncomfortable. Zhukov was a small and thin man, so this problem could not be appreciated.

According to Filippov:

“- The cabin in the prototype I-2 was calculated for a gnome, or in any case not for a normal man. You can sit on it only from the side because the instrument panel is very close… Despite the good flight characteristics this plane can only be seen as a competition plane.”

Opinions about the plane were different not only among the pilots. To clarify the truth, a commission was called, which defined that criticism of the I-2 was harmful and threatened the delivery times. The commission itself inadvertently contributed to this, since the report of its work was delivered only on February 3, 1925.

The tests at the Scientific Experimental Aerodrome (NOA according to the acronym of Nauchno Opytni Aerodrom) began only from March, but already from the first flight new problems with the plane began to appear.

It was pointed out that the model was dangerous from the point of view of the possibility of fire because gasoline was leaking from the hose that started from the upper fuel tank. This was an issue easily resolved by any mechanic, but for inexplicable reasons and due to bureaucratic rules it became necessary to sign and approve a pile of papers before solving the problem.

The NOA tests showed some longitudinal instability, so it was proposed to increase the empennage surface. In April the new queue was built and installed. These were the last flights in Moscow of the prototype I-2.

All subsequent work on the I-2 would be developed in Leningrad. Some sources detail that the cause of the abandonment of Moscow was due to disagreements between Grigorovich and the director of GAZ No.1 Niemtsov. In any case, by the beginning of 1925 the Aviotrust management had decided to create a naval aviation construction department in Leningrad and there was no better candidate than Grigorovich to lead it.

Grigorovich and his group received Factory No.3 “Krasni Liotchik” (later Factory No.23) as a production base. Although it was expected that the main task of this Factory would be the production of seaplanes, the improvement works on the I-2 fighter were moved to this new location together with its author. For this reason, on April 30, 1925, the fighter was disarmed and transferred by rail to its new destination.

Flight tests in Leningrad were carried out between May 25 and June 25, 1925 with pilots AD Mielnitsky and LI Giks at the controls.

Once again ideas and desires arose to improve flight control, increase the wing area, enlarge the cabin and even install a turbocharger.

By that time preparation for series production at the GAZ No.1 and GAZ No.3 factories finally began, so Grigorovich had no intention of risking changes. The I-2 entered production with a whole collection of problems and limitations and still very far from being able to satisfy the requirements of the VVS.

Even without concluding the tests, at the end of April 1925, the Technical Scientific Committee of the VVS issued a request to produce a small experimental series of 10 copies I-2, despite not reaching the maximum speed nor some important features. The production of the Polikarpov IL-400 fighter, which had now been renamed I-1 in VVS documents, was also being prepared. The first pre – series copies of both manufacturers began to fly at the beginning of 1926, but by March of that year the NOA specialists expressed their dissatisfaction in relation to the Polikarpov model. This conclusion was reinforced by the doubts caused by the use of a wooden cantilever wing in a fighter and the control problems associated with piloting techniques, an opinion that would be reinforced after the destruction of two I-1 specimens during the tests, both product of the flat spin entry.

In this way, Grigorovich ‘s model remained as the only competitor to the VVS hunting post. The military, despite approving the introduction of the model, kept demanding the improvement of the plane. This would be tried in a new version that saw the light with the denomination I-2bis.

Serial production began in 1926 and continued until 1928. During this period the GAZ No.3 factory delivered 62 examples of the model not counting the prototype, which had been created at GAZ No.1 in Moscow.

The I-2 was the first Soviet-built fighter to enter service with the VVS. For its time it was a fairly complex fighter. Unfortunately, the model was over-heavy. The lack of standards in the industry caused the examples to differ from each other, which created great differences in performance from one aircraft to another. The cabin was cramped, the pedals were poorly arranged, the weapons were inconvenient to use, the visibility from the cabin was not good. Nor was it possible to definitively solve the problem of engine overheating, carried over from the I-1 model. To improve cooling in some examples, two Lamblin radiators were installed between the landing gear. This version of the plane received the name I-2 prim and was characterized by improving the cooling issue, affecting performance.

Despite the fact that the VVS, in the absence of better options, approved the introduction of the I-2 model in service, the military kept demanding the improvement of the aircraft. These improvements would come in a new version that came to light with the I-2bis.

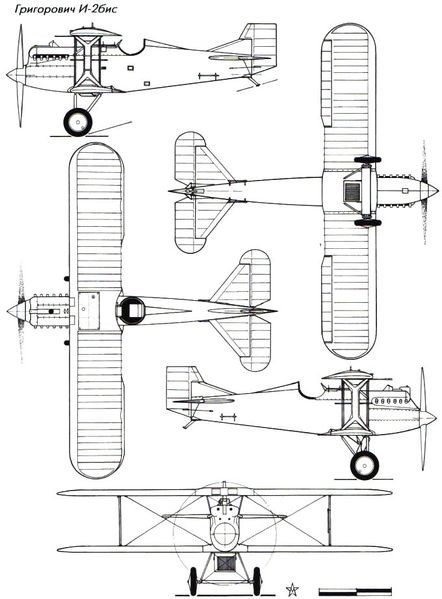

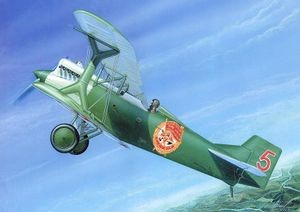

The Grigorovich I-2bis (Russian: Григорович И-2бис) was a version of the I-2 in which some structural reinforcements were introduced and the technological process was improved in order to facilitate production. The cockpit was enlarged and the distribution of instrumentation and equipment was improved. From the external point of view, the new interwing struts, modifications to the landing gear, tail unit and improved hood shape were easily noticeable.

Grigorovich’s I-2bis fighter incorporated few visible changes. Perhaps the most noticeable were the coatings on the interalar supports. In general, it was a single-engine, single-seat biplane of conventional configuration, built of wood and fabric.

The fuselage had an oval section and in the bow section it had a metal structure to which the power plant was attached. Starting from the pilot’s cabin, the fuselage became a wooden construction with a monocoque structure and sheet metal covering, glued around the structure.

The biplane wingbox featured wings of equal span, without offset. The upper plane was fixed by means of an N-type structure built with steel tubes and the planes had X-shaped supports made of duralumin. Unlike the I-2 this structure lacked the fairings on the ends. Wing stiffness ended up being achieved by paired tension cables. Other differences from the original I-2.

The wing was built of wood and featured a double spar structure. The ailerons were located only on the lower wing, protruding slightly outside the trailing edge. The wing skin was made with plywood up to the location of the first spar. From there tissue was used. The trailing edge was made with steel cables and in the plan view it was shown as the wave trace.

Both the tail and the wings were built on an aluminum frame covered in fabric.

The landing gear had a pyramidal structure quite characteristic for the time. The supports were made of steel tubes and the amortization was achieved by means of 16 mm diameter rubber tensioners.

The I-2bis kept the M-5 engine with V-cylinders and 400 hp (licensed copy of the North American Liberty L-12 engine). It stood out for the careful work on the engine hood, of which at least two types were used. The most remarkable symbol of the upper region of the hood was the pipe through which the air flow entered the two “Zenit” carburettors. Cooling was basically achieved by means of a Lamblin radiator that could vary its angle of incidence by around 70º. The control of this radiator was carried out from the cockpit. A number of I-2s were delivered with fixed radiators attached to the fuselage.

In front of the cockpit, in the central section of the fuselage, the main fuel tank with a capacity of 200 liters was located. Another 96-liter fuel tank was located in the center plane, in the center of which was a fuel-in-tank sensor using a float.

The I-2bis’s armament comprised two 7.62mm Vickers or PV-1 machine guns with 500 rounds each. In most of these examples the machine guns were inserted somewhat deeper in the fuselage.

The first I-2bis was obtained as a modification of a production I-2 appearing in the spring of 1927. Even without finishing their flight tests, the VVS requested a series of 140 copies, which would soon be reduced to only 50. Despite the fact that there are documents that establish the delivery by GAZ No.1 of Moscow of 7 I-2bis fighters in 1927, subsequent investigations by M. Maslov confirm that this could not happen. It is not ruled out that it could be some copies with a certain level of modifications, delivered under the name I-2bis, but clearly it is not the same model that later coined this name.

According to IM Kostkin, one of the creators of the Polikarpov IL-400 and later in charge of the serial introduction of Grigorovich’s fighter at Moscow’s GAZ No.1, the first “real” I-2bis was ready only in the summer of 1928. Preparation for serial production at this factory was plagued with problems due to difficulties with the shipment of technical documentation from Leningrad. For this reason, many of the construction elements were redesigned, which resulted in a decrease in the flight characteristics of these specimens. This caused pilots to rate the I-2bis as an inferior model to the I-2.

In the minutes of the conclusion of the tests of the I-2bis fighter, signed by the head of the NII VVS Gorshkov, it was highlighted:

“The I-2bis aircraft with its low speed, climb and ceiling, as well as poor manoeuvrability cannot be considered a modern fighter. Compared to the I-2 it is inferior due to its performance, but the constructive and operational changes make it a better plane. After the elimination of the problems indicated in I-2bis it could be used as a transition training aircraft.”

It was clear that the VVS were in a difficult situation. Polikarpov’s I-3 fighter was just beginning to be built, there were no other domestic candidates, and buying modern fighters abroad was too complicated at the time. Precisely for these reasons in the meeting with the head of the VVS PI Baranov, held in the fall of 1927, it was decided to build the I-2bis knowing that it did not fully meet the requested requirements.

The Moscow GAZ No.1 would build 50 copies I-2bis. Starting in 1927 and as part of a further restructuring of the aircraft industry, GAZ No.1 was renamed Factory No.1 Aviajim.

GAZ Factory No.3 (from 1927 Factory No.23) in Leningrad would produce between 1928 and 1929 28 examples of the modified fighter, bringing the total number of aircraft produced between I-2 and I-2bis to 140 copies.

Although production of the I-2 and I-2bis officially ended in 1929, isolated examples were delivered some time later. The last of these was the I-2bis with serial number 1990, delivered in May 1931 to the Borisoglebsk Flight School (actually it was the first I-2bis built modified in 1927 on the basis of an I-2 of series For three years it had been abandoned in the factory before its delivery was defined.

The 50 I-2bis produced in Moscow were delivered to units in Gatchina (Trotsk), Bryansk and Vitebsk. Some examples from the beginning were delivered to flight schools, so by 1929 they were used at the Borisoglebsk Flying School.

The first two I-2bis arrived in the summer of 1928 at the Bryansk 15th Aviation Brigade and by the end of the year their number had risen to a dozen. At the beginning of 1929 from the experiences of exploitation in Bryansk a report was written in which the I-2bis was evaluated as heavy and inert at the controls. It was noted that the dive was stable, but it was difficult to get out of it.

From the end of 1928 the I-2bis produced by the GAZ No.23 of Leningrad began to arrive at the units. These specimens were characterized by a better finish and superior performance.

According to a report by the engineer PM Kreison issued in the summer of 1928, at that time 62 examples of the I-2 and I-2bis versions were in service. Most of them were located in the Leningrad military region and the Baltic aviation.

The report highlights:

6 I-2s in the 1 Gatchina Squadron;

10 I-2 in Krichevitsi’s 11 Squadron;

4 I-2s in the Caucasus Special Army, in Baku;

7 I-2 in the Vitebsk 7 Squadron;

7 I-2s at the Orenburg Air Combat School;

Some unspecified amount at 44 Bryansk Air Park;

An unspecified number in the 17th Squadron of the 15th Aviation Brigade.

In 1928, following an agreement with the Persian government, it was decided to sell to this country a certain number of R-1 reconnaissance planes, U-1 trainers and I-2bis fighters. These copies were built under a “special task”. At least 8 examples were built in this batch, bearing serial numbers 2116, 2117, 2118, 2119, 2120, 2121, 2122, 2123. These I-2bis were armed with Vickers machine guns and featured increased radiators to enable warmer weather operations. The fighters were packed in boxes for shipment by sea and the spare parts in other smaller boxes. No evidence has been found to show that this export took place.

It should be noted that between 1925 and 1926 Grigorovich worked on the projects for improved versions of the I-2 fighter. The first version, sometimes known as the Grigorovich I-3, kept the Liberty engine, but had to reach 270 km/h. A later version incorporated a Wright Tornado 3 engine. Named I-4, it was to reach a maximum speed of 300 – 350 km/h with a flying weight of 2,000 kg. These projects never got past the stage of conceptual ideas.

Versions:

I-2 – Original version of the fighter developed on the I-1 model. First flight on November 4, 1924. 62 examples were built in the Leningrad GAZ No.3 between 1926 and 1928.

I-2bis – Improved version with structural reinforcements, wider cabin, new inter-wing mounts, changes to the landing gear, tail unit and new drive cowling. It was produced at factories No.1 in Moscow (50 copies) and No.3 in Leningrad (28 copies).

I-2prim – A number of modified aircraft with two Lamblin radiators between the landers. This version was characterized by improving the issue of cooling, affecting performance.

Type: I-2

Powerplant: 1 x 400 hp M-5 V-12

Wingspan: 10.80 m

Wing area: 23.46 m²

Length: 7.32 m

Height: 3.00 m

Empty weight: 1130 kg

Loaded weight: 1530 kg

Fuel + lubricant capacity: 236+35 kg

Maximum load capacity: 400 kg

Wing loading: 57.5 kg/ m²

Power load: 3.8 kg/hp

Speed at sea level: 240km/h

Maximum speed at 1000 m: 239 km/h

Maximum speed at 4000 m: 230 km/h

Landing speed: 95 km/h

Range: 650 km

Endurance: 2.5 h

Service ceiling: 5740 m

Rate of climb: 420 m/min

Turn time: 13s

Time to 1000m: 2.1 min

Time to 2000m: 4.6 min

Time to 3000m: 8.2 min

Time to 4000m: 13 min

Time to 5000m: 21 min

Landing run: 190m

Take-off run: 120m

Armament: 2 x 7.62mm PV-1 machine guns

Accommodation: 1

I-2bis

Powerplant: M-5 400 hp

Wingspan: 10.80m

Wing area: 23.46 m²

Length: 7.32m

Height: 3.00m

Empty weight: 1,152 kg

Loaded weight: 1,575 kg

Wing loading: 66.92 kg/m²

Power Load: 3.8kg/hp

Top speed: 235km/h

Cruising speed: 190km/h

Landing speed: 95km/h

Rate of climb: 420m/min

Range: 600km

Endurance: 2.5 hours

Turn time: 16 sec

Service ceiling: 5340 m

Time to 1000m: 2.4min

Time to 2000m: 5.5min

Time to 3000m: 9.6min

Time to 4000m: 15min

Time to 5000m: 25min

Landing run: 210 m

Take-off run: 160m

Armament: two 7.62mm PV-1 synchronized machine guns

Accommodation: 1