Despite the failure of the 2I-N1 fighter, the VVS was not willing to give up having a two-seat fighter. In 1927 it was decided to obtain a model from the I-3 single-seat fighter, which was successfully mass produced.

Nikolai Polikarpov considered it more important to work on the creation of the I-5 single-seat fighter with an air-cooled engine and expressed his opinion at the meeting of the Aviotrust technical committee, held on August 12, 1927. Despite his opinion, the development of the I-5 fighter with a 480 hp Gnôme-Rhöne Jupiter engine was entrusted to TsAGI and the OSS collective, under the direction of Polikarpov, received the task of creating the D-2 or DI-2 (Russian: Поликарпов Д-2 (ДИ-2)) two-seat fighter. with 500 hp BMW VI engine.

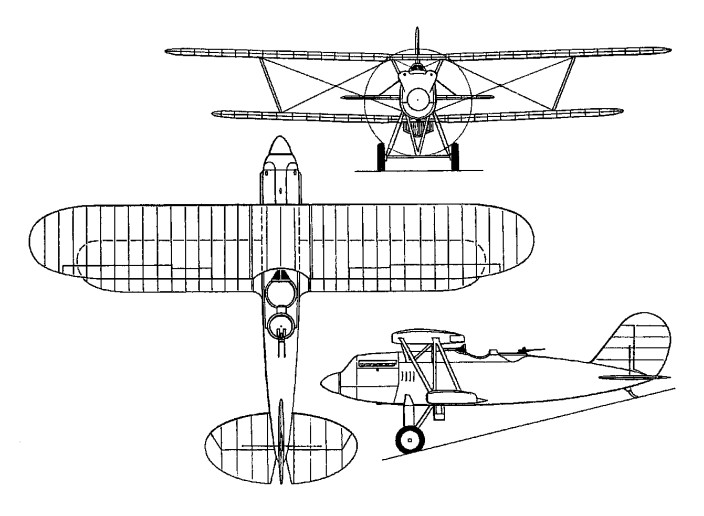

Constructively, the DI-2 two-seat fighter repeated the layout and characteristics of the I-3 single-seat fighter.

The construction was mixed. The fuselage was presented as a monocoque wooden structure. The structure was made up of 4 stringers, 4 stringers and 13 frames. The stringers were constructed from rectangular pieces of pine wood. Towards the tail section the sectional area of these spars decreased.

The construction of the fuselage at Factory No.25 was carried out in two halves. On a mold with the appropriate shape, the coating began with sheets of birch bark in several layers, fixed with the use of glue. In the bow area, 5 layers were used and only four in the tail area. Between each application of a layer, the previous one was left to dry for 6 – 7 hours. Once the gluing process was completed, the entire structure was left to dry for 10 – 12 days.

The two halves were located on the wooden structure, fixed with screws and nails. In the joining area, a 50 mm wooden strip was placed, which was glued and also fixed with screws. The fuselage, once completed, was painted with two layers of enamel and the bow area was protected by sheets of duralumin.

The engine cowling was fixed to the structure, in the same way as the upper part of the fuselage located from the machine gun position to the windshield of the pilot’s position. Behind the gunner’s position the fuselage continued with a duralumin upper fairing, which could be removed and to which the rudder control cables were attached.

The wing box was made up of planes of different spans joined by N-shaped supports made of aluminum tubes. These supports were fixed to the wing using screws, which also served to adjust the wing. The upper and lower planes had a Clark Y profile and a double wooden spar structure with plywood covering from the leading edge to the first spar. The upper plane featured ailerons constructed from a fabric-covered duralumin structure. To attach the ailerons, the upper plane had a third additional spar.

The upper center plane in its front part had two tanks intended to store water and fuel. The fuel tank, with a capacity of only 2.5 liters, was used to start the engine, reaching the engine by gravity. The second, slightly larger tank was part of the engine cooling system. This system was composed of a retractable honeycomb radiator. The retraction system was operated from the cockpit using a crank located on the left side of the cockpit.

The tail unit featured aluminum construction. The keel was made of wood and was incorporated into the structure of the plane. To facilitate flight control in different regimes, the stabilizer could vary its deployment angle. This angle could be modified by the pilot in flight using a lever located on the right side of the cockpit.

The landing gear was of the conventional type with a tail skid. The main landers featured a steel skeletal structure with duralumin fairings with a central flat piece within which the rubber shock absorbers were located. The half-axles of the wheels in the central area were joined by a common axle. To guarantee greater rigidity, support arms were used. The spoked wheels had dimensions of 800 x 150 mm. It is noteworthy that in many cases the spokes were covered by duralumin discs to improve rigidity. The tail skid was made of duralumin and had cushioning using a rubber strip. Its operation was synchronized with the position of the rudder.

In winter the wheels were replaced by ash skis similar to those used by the R-1.

The D-2 was equipped with the BMW VI liquid-cooled engine with a nominal power of 500 hp and a maximum calculated between 680 and 730 hp. This engine was considered high altitude, prepared to obtain its highest performance at altitudes of 2500 – 2700 m.

The fuel system, apart from the small tank on the upper plane, consisted of a tank located in the fuselage. The engine was powered by AM type fuel pumps that were driven by the engine itself.

The engine was started by using a 5 liter cylinder of compressed air. In case of failures, an emergency starting system was used.

The cockpit equipment was quite standard for a fighter of the time. Of note is the use of a large AP compass located under the instrument panel, between the pilot’s legs.

The D-2’s armament consisted of a pair of synchronized PV-1 machine guns firing through the propeller and one or two PV-1 machine guns in a ring mount located in the gunner’s cockpit. For aiming, the pilot used an OP-1 type collimator located in the center of the windshield. As additional support, a KP-5 annular mechanical collimator was located on the right side of the fuselage and near the windshield.

The technical task for the construction of the two-seat fighter was modified several times. In 1928 Polikarpov received the task of designing the ND-2 night fighter and the builder himself presented a version with a 480 hp Gnôme-Rhöne Jupiter radial engine. However, these “deviations” were discarded and finally the D-2 was built from the original specifications.

The BMW VI- powered D-2 prototype was built at Factory No.25 in the spring of 1929.

Factory tests began on March 15 and lasted until July 1929. The plane was flown by test pilot BL Buxgolts and in his opinion the plane showed no disadvantages of any kind in relation to most fighters of the time. With the installation of more powerful weapons, this fighter could be more effective than single-seat fighters.

On the other hand, Buxgolts highlighted that the D-2 had a centering that was too late, which affected the characteristics of the plane in a spin.

After the development of the tests, the plane remained abandoned for a long time, almost a year, due to the lack of requests for the continuation of the work. By this time Polikarpov was arrested and Factory No.25 was absorbed by Factory No.39.

In the spring of 1930 work on the D-2 fighter was continued. In order to improve the behavior in spin, the tail unit was modified by adding V planes located with an inclination of 8º with respect to the horizontal. This type of tail was used for the first time in the USSR).

Other modifications included the addition of a TUR-7 turret to the rear gunner position. This new installation was simply a TUR-6 ring mount with the ring diameter reduced from 710 to 636 mm. Two paired Lewis machine guns were originally installed there, but later a single Degtiariov light machine gun for aircraft was located there.

On June 13, 1930, the first flight was made with the new V-tail unit. Kozlov was appointed as test pilot. The following days were dedicated to making certain adjustments and the aircraft was transferred to the NII VVS to begin state testing.

In the NII VVS the D-2 was flown by Buxgolts, Zhukov and Pisarienko. None of these pilots in their reports stated anything in relation to the new tail unit. Only Buxgolts describes that he failed to notice any improvement in the plane’s behavior.

The general assessment was positive, considering that the D-2 was overall a good combat aircraft. A request was made to develop a small batch in series, mainly motivated by the need for VVS in two-seat fighters.

At the end of July 1930, pilot Vladimir Ivanovich Chekariov joined the D-2 tests. By that time, a total of 6 hours and 48 minutes of flight had been reached.

On August 4, 1930, Chekariov received the task of testing the control of the D-2 at altitudes of 3000 m, but the first flight of the day, carried out together with the observer Vasily Ivanovich Blagonadiezhni, was intended to measure the maximum ceiling of the plane. Equipped with oxygen cylinders and masks, the pilots soared until they reached a height of 7,170 meters and landed happily.

After a rest they began to prepare to make the second flight. Responsible for the flights that day was the head of the first brigade of the fighter department of the NII VVS Nikolai Alexeyevich Zhemchuzhin. According to his words, the pilot Chekariov, when heading to the second flight, said: “Now I will tame him as he should. ”

The pilot was referring to pushing the plane with maximum overloads. Zhemchuzhin snapped: “Stop this nonsense, this is not the VT” (he was referring to the VT-11 or I-5, flown by Chekariov).

Among the ground observers were the renowned builder and assistant to the head of the TsKB-39 D. P. Grigorovich and the deputy head of the TsKB I.M. Artamonov. According to their statements, after executing its task the plane came out of the clouds at a height of 1,200 m and then began to descend in a spiral to about 100 m. Observers noted a strong vibration in the tail, which would soon be accompanied by the destruction of the right section of the stabilizer. This caused the destruction of the wing box and the plane hit the ground. The crew died instantly. Despite having both parachutes, it was impossible for them to leave the plane due to the low altitude.

Investigations showed that the vibration in the tail had been noticed before, but none of the testers had given it importance. It was considered that when the tail was raised, the upper wing exerted an important influence on its operation, which caused these vibrations.

It was considered that the rough handling of the plane resulted in damage to the attachment points and the vibration accelerated the process, which ended in the destruction of the tail.

With the loss of the D-2 the small batch approved for production was cancelled. The accident contributed to worsening the position of the detained Polikarpov and his specialists.

Despite the loss of the D-2 prototype, work on the development of two-seat fighters did not stop. Following VVS requirements, the development of a combat and reconnaissance version with a BMW VI engine began , whose model was presented for evaluation on October 8 , 1930 . This project would never be finished because the DI-3 would soon appear, created in the OGPU system and in which great hopes were placed.

Powerplant: 1 x 730 hp BMW VI

Wingspan: 11.80 m / 39 ft 9 in

Wing area: 31.80 sq.m / 342.29 sq ft

Length: 8.20 m / 27 ft 11 in

Height: 3.12m

Max take-off weight: 2122 kg / 4678 lb

Empty weight: 1557 kg / 3433 lb

Fuel capacity: 210 kg

Lubricant capacity: 33 kg

Total load capacity: 565 kg

Wing loading: 67.0 kg/m²

Power load: 2.9 kg/hp

Max. speed: 256 km/h / 159 mph at SL

Speed at 5000 m: 243 km/h

Landing speed: 100 km/h

Cruising speed: 231 km/h

ROC: 455 m/min

Range: 510 km / 317 miles

Endurance: 2 hours

Service ceiling: 6,300 m

Spin time: 14s

Time to 1000 m: 2.2 min

Time to 2000 m: 4.5 min

Time to 3000 m: 7.2 min

Time to 5000 m: 17.5 min

Landing run: 250 m

Takeoff run: 180 m

Armament: 4 x 7.62 mm PV-1 machine guns

Accommodation: 2