The requirement for a new multi-role combat aircraft (MRCA) to equip the German Luftwaffe and Marineflieger, Italy’s Aeronautica Militare and the UK’s RAF was established in the mid-1960s. This led, on 26 March 1969, to formation of the European industrial company Panavia Aircraft GmbH, combining the aviation talents of Aeritalia, British Aerospace and Messerschmitt-Bölkow-Blohm to design, develop and manufacture this important aircraft. The feasibility study for an aircraft to meet the tri-national requirements was completed by 1 May 1969, and within four years a go-ahead for the Panavia MRCA was given; between then and the flight of the first prototype (D-9591), flown at Manching, Germany on 14 August 1974, piloted by the project test pilots, Paul Millett with Nils Meister in the second seat. This is the first of nine prototypes and six pre-series aircraft to fly. Two more prototypes were to fly at Warton, one at Manching and one at Caselle.

The initial production agreements for the Tornado envisage a total of 809 aircraft and comprise 644 of the (IDS) interdictor/strike version for the Aeronautica Militare (100), Luftwaffe (212), Marineflieger (112), and RAF (220), plus an additional 165 examples for the RAF of the air-defence variant (ADV, first flown in October 1979).

The aircraft has variable geometry wings and is powered by two Turbo-Union RB199-34R turbofans, with a maximum speed of 1452 mph and a service ceiling of 50000 feet. The Air Defence Variant (ADV) version of the Tornado is optimised for long-range interception with radar and infra-red guided air-to-air missiles and one internally mounted 27mm Mauser cannon.

Compared to the initial IDS variant, the Tornado ADV has a longer fuselage with additional fuel capacity, a better fineness ratio for enhanced transonic acceleration, and the possibility of locating four Sky Flash air-to-air missiles in semi-recessed positions in the lower fuselage.

The air defense variant (ADV) of Tornado, developed specifically for the RAF as a long-range air defense interceptor has GEC-Marconi Foxhunter multimode radar in place of the IDS’s ground-mapping radar and terrain-following radar, although some 80 percent commonality was achieved between the types.

The first production IDS versions were flown, chronologically, by the UK (10 July 1979), West Germany (27 July 1979) and Italy (25 September 1981), early production aircraft going to the Trinational Tornado Training Establishment (opened in 1981) which was set up at RAF Cottesmore and which, by August 1982, had received its full complement of 50 aircraft. The RAF also has a Tornado Weapons Conversion Unit (TWCU) at RAF Honington, the other three services each conducting their own weapons conversion training with national avionics and weapons.

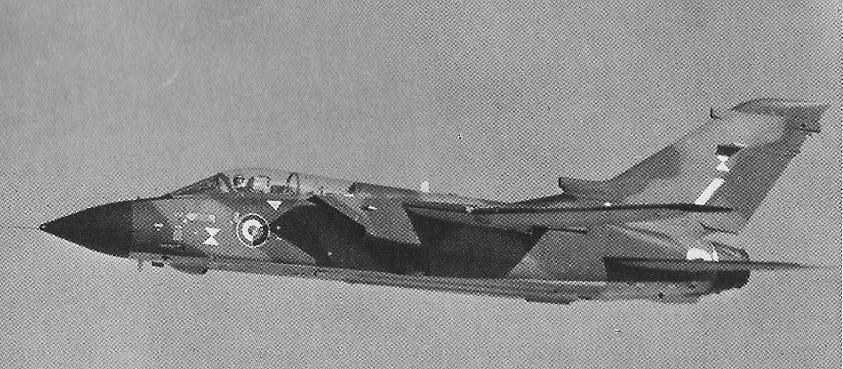

The first of 229 Tornado GR.1 strike aircraft was delivered to the Royal Air Force in 1981 and the first squadron equipped with the aircraft became operational in 1982. The GR.1 is capable of carrying a wide range of armaments, including conventional and anti-airfield bombs, laser-guided bombs, air-to-ground rockets and anti-radar missiles.

Early tests carried out in 1980 showed that the aircraft’s weapon system was capable of highly accurate bomb delivery, and this has been confirmed more recently by Tornados competing for the first time in the USAF’s 1984 ‘Giant Voice’ bombing competition held in South Dakota. Tornado GR.Mk1s of No. 617 (Dambuster) Squadron, competing against Boeing B-52s and General Dynamics FB-111As of Strategic and Tactical Air Commands, and RAAF F-111Cs, took first and second place in the LeMay Trophy contest (high-and low level sorties) first and third places in the John C. Meyer Trophy contest (for the best non-B-52 crew in low-level attack) and second and sixth place in the Mathis Trophy contest (for the best high and low-level team bombing scores). This is the first time that teams from outside the US have won the LeMay or John C. Meyer trophies, and such capability augurs well for the Tornado and NATO.

Features of the design include a variable geometry wing, sweeping from 25′ to 68′, two RB199 three-shaft turbofans developed by Turbo-Union, (which combines Fiat Aviazione, MTU München and Rolls-Royce) and, because of the trinational requirement, some variations in avionics and communications equipment.

This advanced equipment provides each nation with an aircraft having day and night all weather extremely low-level interdictor/ strike capability, the RAF designating this version Tornado GR.Mk1.

The first prototype of the RAF’s ADV variant, designated Tornado F.Mk2, was flown first on 27 October 1979, and this differs structurally in having the overall length being increased by 4 ft 5.5 in (1.36 m) to permit tandem carriage of AAMs, and the fixed portion of the wings being extended forward, increasing chord. Increased internal fuel capacity, plus drop tanks on the inner underwing stations, allowed one of the prototypes to demonstrate a 2 hours 20 minutes combat air patrol (CAP) on station 374 miles (602 km) from base, but a nose-mounted (port) retractable inflight-refuelling probe will allow more extended CAPs. Armament of this version comprises a 27-mm IWKA-Mauser cannon in the fuselage, plus two AIM-9L Sidewinder (underwing) and four Sky Flash (underfuselage) air-to-air missiles. The first two Tornado F.Mk2s for RAF service were handed over to the F-2 Operational Conversion Unit at RAF Coningsby, Lincolnshire in early November 1984.

Apart from dual controls and minor differences in the navigator’s equipment, the trainer Tornadoes are identical to the strike aircraft and possess full operational capability.

A total of 929 Tornados has been ordered in seven batches for the air arms of the three partner countries and two export custom¬ers. In addition, four development aircraft will be reworked to production standard. Production in Italy was completed by 1987, but continues at a rate of 44 per year in the UK and 42 per year in Germany. By mid-1987 620 aircraft had been delivered. Two basic versions are in production:

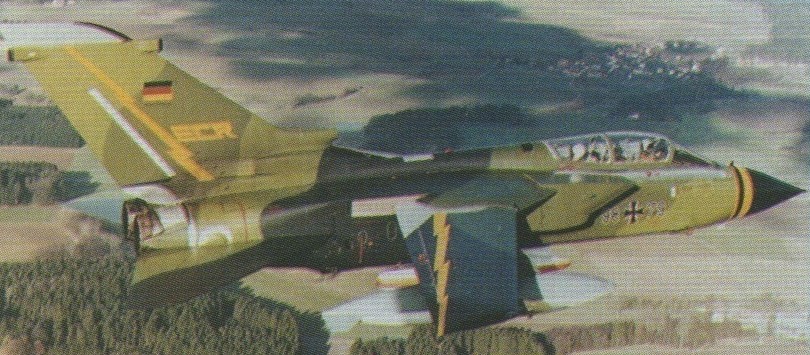

IDS The sixth batch of aircraft already incorporates some avionic upgrades, including the MIL standard 1553B digital databus, uprated mission computers, and missile control systems associated with the integration of Alarm (for the RAF) and AGM-fl 85 Harm (for West Germany). The Luftwaffe selected the electronic, combat, and reconnaissance (ECR) variant of the IDS Tornado in 1986, and placed an order for 35 aircraft. Optimised for the stand-of reconnaissance and anti-radiation roles, the ECR will feature an emitter locator system, a datalink, a low/medium altitude recon¬naissance system, and jammer pods. Normal weapons load will comprise two Harms and two Sidewinder AAMs, with ECM/flare dispenser and external fuel tanks. The twin Mauser 27mm guns are omitted.

ADV The first prototype of the Tornado Air Defence Variant, A01 s/n ZA254, com¬pleted more than 41 hr flying by the end of January 1980 when it went on lay up for the installation of updated equipment. The aircraft made its first flight on 27 October 1979. Early ADVs were fitted with RB.199 Mk.1OU engines and designated F.2s, while the 1987 production model is the F.3 with Mk.104 engines and other equipment upgrades. F.2s will be retrofitted to F.3 standard except for the engine change, and will be known as F.2As. Designed specifically to meet RAF require¬ments for a long-range all-weather interceptor, the Tornado ADV features an advanced track-while-scan pulse-Doppler radar, twin inertial platforms, an updated main computer, advanced displays, and (on the F.3) automatic wing sweep and the automatic manoeuvre device system which controls flap/slat scheduling. Initial armament consists of mixed of Skyflash and Sidewinder AAMs.

The RAF’s first Tornado fighter squadron, No. 29, was equipped with Tornado F.3s, the definitive version powered by RB.199 Mk.104s and carrying four Sidewinders (instead of two as on the F.2) plus four Sky Flash missiles.

The 1990 cancellation of 33 Tornados for the RAF meant that production was likely to end in 1992. To 1990, more than 900 Tornados had been ordered for the air arms of the three partner countries and Saudi Arabia, with other export orders in abeyance. As well as operating the IDS attack version, the Luftwaffe is receiving 35 electronic, combat and reconnaissance (ECR) variants. Four Skyflash AAMs, Sidewinders and a 27mm cannon armament.

The ECR (electronic combat and reconnaissance) version was a Tornado variant developed by the Germans for the reconnaissance role and suppression of enemy air defense with the AGM-88A HARM anti-radar missile.

The first production Tornado ECR flew on 26 October 1989.

The RAF received 170 ADVs, of which 152 were in F.Mk 3 improved form. Saudi Arabia was the only other customer, having 24.

GR.1 is the RAF designation for the RAF Tornado IDS aircraft. The GR.1A was a modified variant optimized for the recconnaisance role and the GR.1B for the maritime attack role equipped with Sea Eagle missiles.

Intended as a mid-life update of the Tornado GR.1 fleet, deliveries of the Tornado GR.4 began in October 1997. All GR.1 and GR.1B aircraft that remained in service were upgraded to GR.4 standard. All GR.1A have been upgraded to GR.4A, the reconnaissance version of the GR.4. The GR.4/4A update enables the RAF Tornado IDS aircraft to remain in service for at least another 10-15 years. While the performance of the aircraft is similar, overall effectiveness is enhanced by a forward–looking infra-red system, a wide-angle head-up display, night vision goggles, new defensive systems and avionics and provision for enhanced anti-armour, stand-off attack and laser designation weapons.

A ceremony was held at Warton on June 10, 2003 to celebrate the hand over by BAE Systems of the 142nd and last Tornado GR.4 to the RAF. Over £1bn has been spent on this Mid Life Update which began with contract signature back in July 1994. The first air¬craft was delivered on October 31, 1997, though since then the time needed to do the work on each aircraft has been reduced by 40%. One of the aims of the modification of the GR.1 and GR.1A into the GR.4 and GR.4A respectively has been to give the RAF a common fleet standard. The aircraft is now able to carry more smart weapons such as the Storm Shadow cruise missile as well as use the RAPTOR reconnaissance pod. Other major improvements include a Forward Looking Infra Red (FLIR) sensor, new Head Up Display (HUD), NVG compatible cockpit, GPS navigation, provision for a TIALD pod and new electronic warfare system.

Until delivery of the final aircraft was in 1998, orders covered 781 production IDS Tornadoes for interdictor strike and ECRs for electronic combat and reconnaissance, as 228 IDSs for the RAF, 210 IDS and 35 ECR for the Luftwaffe, 112 IDSs for the German Navy, 99 IDSs for the Italian Air Force, and 96 IDSs for Saudi Arabia.

During the 1991 Gulf War, the Tornado GR.1 force flew 1500 operational sorties mainly against airfields, air defence sites and bridges. Six aircraft were lost in low-level missions.

Germany’s Mid Life Update (MLU) for the Tornado was completed. And also the Italian Air Force (AMI) Tornado IDS and ECR were scheduled to receive a mid life update. AMI Tornado F.3s that were leased from the RAF were returned to the UK, and were to be replaced by leased F-16s until the arrival of the Eurofighter Typhoon.

The UK’s Ministry of Defence was pioneering an approach to building its next-generation Tempest fighter—by recycling retired Tornado jets. Instead of sourcing expensive foreign materials, old fighter jet parts are ground into a titanium-rich powder used for 3D printing new aircraft components.

Rolls-Royce has successfully tested these parts in an Orpheus engine, proving their viability. This initiative not only reduces costs but also strengthens supply chain resilience. With Italy and Japan also involved, the Tempest program is set to revolutionize sustainable aircraft manufacturing, with a planned first flight in 2026 and entry into service by 2035.

While this approach might sound crazy, it actually reduces the country’s reliance on foreign-sourced materials and points toward some incredible new ways to recycle old aircraft.

Introduced as a response to lingering concerns about how the global market for vital materials could be impacted by large-scale war between great powers, this is an area of increasing focus for the Future Combat Air Systems (FCAS) program. The FCAS is Britain’s overarching effort that includes the development of the crewed Tempest fighter.

“Through the expected lifecycle of the U.K.’s FCAS, we expect access to critical materials to be challenged, as global supply chains become increasingly disrupted and competitive. In parallel, there is a societal need to make the best use of the raw materials we already have,” explained the Future Combat Air System’s Sustainability Requirements Manager, identified only as “Squadron Leader Rob.”

To achieve this, rather than just scrapping old Tornado GR4s that were retired from active service in 2019 and then sourcing all the high-quality raw materials needed for the new Tempest fighter program from foreign countries, the U.K. will simply yank parts off of those old Tornados and feed them into an industrial grinder to produce a powder, called “feedstock.” This powder can then be used by industrial 3D printers to produce new components for new fighters.

The British Ministry of Defense, is collaborating with Rolls Royce in the effort.

In testing so far, Tornado engine compressor blades, which include a high quantity of titanium, were cleaned, ground up, and then used to 3D print a new nosecone and compressor blades for “Orpheus” the small engine Rolls Royce has in testing to mature technologies for the Tempest program.

With its new 3D-printed component, the Orpheus engine was then put through the wringer and managed to pass all suitability and safety tests.

“Tornado 2 Tempest is a bold, exciting and innovative project and a demonstration of how excellent collaboration between the MOD, industry and SME can deliver sustainable and technologically advanced solutions,” said Andrew Eady, Rolls-Royce Vice President for FCAS Sustainability.

This same recycling and 3D-printing process can be used for steel and aluminum components as well, which would further reduce waste, and allow the U.K. to have to mine and process fewer raw materials in the future.

“Not only can this solution reduce the costs and burden of sourcing critical and high-value metals, but it can also produce components that are lighter, strong and longer lasting than those made through traditional forging techniques, thereby further enhancing the MOD’s overall sustainability and effectiveness,” Thomas Powell, DRDT’s Strategic & Submarine Recycling Senior Commercial Manager, said in a Rolls Royce press release.

Construction of the first Tempest technology demonstrator began 2024, and the U.K., Italy, and Japan, which are also partner countries in the program, are hoping to see the aircraft make its first test flight in 2026, with the goal of getting these fighters into service by 2035.

Tornado ADV

Engines: 2 x Turbo-Union RB.199

Installed thrust (dry / reheat): 80 / 142+ kN

Span: 13.9 m / 8.6 m

Length: 18.1 m

Wing area: approx. 25 sq.m

Empty wt: 14,500 kg

MTOW: 27,968 kg

Warload: 8,500 kg

Max speed: 2.2 Mach

Time to height: 2 min / 9150 m

Ceiling: 21,300+ m

TO run: 760 m

Ldg run: 370 m

Fuel approx. internal (external): 7300 lt (6000 lt)

Air refuel: Yes

Combat radius: 740+ km

Armament: 8 x AAM, 1 x 27 mm

Tornado IDS

Powerplant: two Turbo-Union RB.199-34R Mk.101 turbofans, 37.70kN (8,475lbst) dry and 66.01kN (14,840lbst) with afterburning

Length 16.72m (54ft 10.25in)

Height 5.95m (19ft 6.25in)

Wingspan at minimum sweep (25 deg) 13.91m (45ft 7.5in)

Wingspan at maximum sweep (67 deg) 8.60m (28ft 2.5in)

Take-off (’empty’) 14091kg (31,065lb)

Max Take-Off Weight 27961kg (61,620lb)

Max level speed ‘clean’ at 11000m (36,090ft) Mach 2.2+/ 2337+km/h /1453+mph)

Service ceiling 50,000+ ft (15420+ m)

Armament: two internal Mauser BK.27 27mm cannons / 180 rounds each

Hardpoints: 9

External load: 18,000 lb / 8165 kg

Max range: 3885 km

Air refuel: Yes

Combat radius hi-lo-hi: 1400 km

Crew: 2

Tornado IDS

Powerplant: two Turbo-Union RB.199-34R Mk.103 turbofans each rated at 38.48kN (8,650lbst) dry and 71.50kN (16,075lbst) with afterburning

Length 16.72m (54ft 10.25in)

Height 5.95m (19ft 6.25in)

Wingspan at minimum sweep (25 deg) 13.91m (45ft 7.5in)

Wingspan at maximum sweep (67 deg) 8.60m (28ft 2.5in)

Take-off (’empty’) 14091kg (31,065lb)

Max Take-Off Weight 27961kg (61,620lb)

Max level speed ‘clean’ at 11000m (36,090ft) Mach 2.2+/ 2337+km/h /1453+mph)

Service ceiling 50,000+ ft (15420+ m)

Armament: two internal Mauser BK.27 27mm cannons / 180 rounds each

Hardpoints: 9

Max range: 3885 km

Air refuel: Yes

Combat radius hi-lo-hi: 1400 km

Crew: 2

Tornado F.2

Seats: 2

Wing span: 45 ft 8 in (13.9m)

Tornado F.3

Engines: 2 x 16,910 lb st (71,2 kN) Turbo-Union RB199 Mk103 turbofans

Seats: 2

Wing span: 45 ft 8 in (13.9m)

Tornado GR.1

Seats: 2

Wing span: 45 ft 8 in (13.9m)

Tornado GR.4