The DI-6 fighter (originally TsKB-11 (Russian: Кочеригин, Яценко ДИ-6)) was a development in 1934 by Kochierigin at the “ Aviorabotnik ” factory. The construction of the DI-6 was commissioned to the aeronautical engineer VP Yatsenko. The new fighter was projected in two main variants: two-seater fighter and attack aircraft. The DI-6 was the first fighter in the world to use a retractable landing gear with shock absorbers located on the main wheel discs.

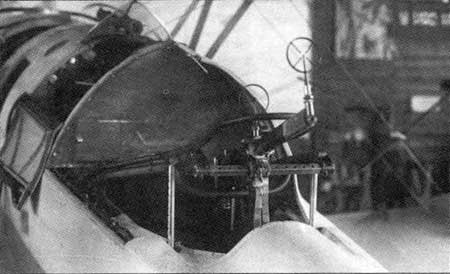

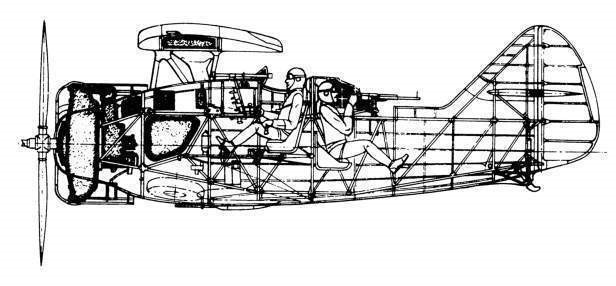

The fighter’s armament consisted of two 7.62-mm (0.30-in) ShKAS machine guns under the wings and another in a ring in the gunner’s cabin, all with 750 rounds. In the attack version, the gunner’s 7.62-mm (0.30-in) ShKAS machine gun was maintained and four PV-1s were added with a total of 3,000 shots (which could reach 4,000 when the plane was overloaded). In the attack aircraft version, in addition to the four underwing mounts, a weapons bay was provided in the fuselage capable of carrying four 10 kg aviation bombs and the ability to locate two VAP chemical weapons containers under the wings. Underwing racks carried four 12-kg (26-lb) bombs.

The selected powerplant was the Yakovlev M-32 water-cooled V-engine, rated at 600 hp at 5000 meters. Six engines of this type had been produced on an experimental basis between 1932 and 1934, with a total of 1,200 hours of work on test benches, presenting so many difficulties that further development was cancelled. This led to major modifications to the fighter’s plans and mockup, to accommodate a 625-hp Wright Cyclone R-1820F-3 engine.

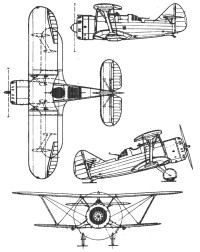

The wing structure was made up of two midplanes (upper and lower) and two pairs of wings joined by X-shaped studs. Both the upper and lower wings had a double spar structure made of wood with a fabric covering. The upper flange was built to the Clarke UN profile with a relative thickness of 10%. The ailerons with a duralumin structure and textile covering were located only on the upper wing. Two 76-liter fuel tanks were located in the center of the upper wing, which were characterized by their tendency to leak due to the poor quality of their finish. The thickness of the upper centerplane tended to decrease towards its center, being fixed to the fuselage by means of two N-shaped uprights made of chrome-molybdenum tubes.

The fuselage was built of chrome-molybdenum tubes. The fuselage frame was welded to the engine base and lower centerplane. The front cover was made of aluminum sheets. In the back, the covering was made of fabric. The tail was monoplane and of the conventional type. Both the rudder and the elevator were made of duralumin and covered with fabric. The empennage was built in its lower metal part, in the area where the stabilizers were fixed. The upper part featured a duralumin structure and a fabric covering.

The retractable landing gear featured 750х125mm main wheels with brakes and an internal hydropneumatic damping system. The retraction was carried out by means of a pneumatic system with compressed air and there was a mechanical system for emergencies. The tail skid was fixed and had hydro-pneumatic shock absorption.

The cockpit was of the open type with a tempered glass windshield. The pilot’s seat was adjustable to accommodate his height. To improve the pilot’s field of vision to the rear, the gunner’s cabin was located at a lower level. This cabin was closed on three sides with transparent celluloid panels and featured glass windows on each side. The shooter had two seats: the main one, facing away from the pilot and used to operate the ShKAS machine gun, and an additional one that folded towards the right wall of the fuselage. The gunner’s cabin windshield was made up of two panels that had to be released in case of emergencies to allow the gunner to leave the aircraft.

In September 1934 the first experimental prototype TsKB-11, with its wings painted red, was delivered to the NII VVS for state testing. IF Petrov was appointed as main test pilot and Vinogradov as gunner. For Factory No. 39, test pilot Yu participated in the tests. I. Piontkovsky and the head of the experimental flight station N. Nikolayev. The first flight was carried out by the NII VVS AI Fili on September 30 and the second flight was only possible in December. During this time, the plane’s engine was replaced, the angle of the stabilizers was modified, and the landing gear retraction system was improved.

The retractable landing gear added some difficulties to the tests due to the lack of experience of the pilots with its handling. Thus, for example, on December 10, during a test flight, the main units could not be retracted due to an error by pilot Petrov in the sequence of the procedure. The following day, during the landing due to another problem, the plane was forced to land on its belly, resulting in slight damage. As a curious fact, the NII VVS sent an information to the Commissioner of heavy industry Sergo Ordzhonikidze, blaming the pilot IF Petrov for the failures. Petrov was called to clarify the facts, of which he made a detailed exposition. Upon returning to the institute, he was informed that by order of the commissioner and in gratitude for his conduct, he was given a new GAZ-1 car.

In the test results report, it was pointed out that due to engine problems in some flight regimes, there was vibration in the wings, especially on the left. The wing entered into resonance with the engine. During the takeoff roll, there was a tendency to lift the tail and the aircraft pulled to the left, which complicated takeoff during takeoff from unprepared aerodromes. The use of the reserve system for the extension of the landing gear demanded a lot of physical strength from the pilot. The lack of effectiveness of the ailerons made the plane tend to turn in flight. Another deficiency detected was that the pilot with his winter coat and parachute was unable to board or leave the device without help in an emergency. The gunner lacked communication with the pilot, which almost made it impossible at high altitudes or when the engine worked at high revolutions. Poor visibility from the cabin downwards and poor firing angle from the rear cabin were highlighted. In an emergency, the gunner did not find it any better than the pilot to leave the aircraft due to the narrowness of the access hatch and the need for great physical force to open the cover.

However, the conclusions were generally positive. The speed, the manoeuvrability and the absence of major defects, made it possible to suppose that the indicated problems could be solved in a short time, highlighting the great interest of the air forces in having an aircraft of its type. The report also pointed out the need to force the development of a second prototype with weapons and deliver it for testing, as well as prepare the conditions to build a small series. Factory No. 39 was asked, in parallel, to develop a single-seat escort fighter variant.

In relation to the landing gear and the wheels with internal cushioning, the report considered that the tests passed. Both the retraction and wheel scheme were recommended as a successful product. The NII VVS received the modified TsKB-11 in May 1935. On this occasion the testers of the aircraft were P. Ya. Fedrovi and VA Stiepanchonok. The tests culminated in November with results considered positive. Weapons were included in these tests, which also received a positive assessment. During these tests the pilots developed the tactical methods of using the new machine. In the surviving reports of the NII VVS several pages can be seen with schemes of variants to attack air targets and manoeuvres to defend against enemy attacks.

Among the deficiencies noted was again the lack of gunner firing angles that allowed the enemy aircraft to easily destroy its tail from the 6 o’clock position. The gunner’s position was awkward, adding to the fatigue. To retract the landing gear the pilot needed to perform 9 operations. Both the wings and the tail began to vibrate when the plane dived. There was a lack of communication between the pilot and the gunner and the difficulties faced by the latter in the event of having to abandon the aircraft in an emergency.

The conclusions of the NII VVS were presented to the head of the VVS RKKA Yákov I. Álksnis, who asked the head of the GUAP to order Factory No.39 in the shortest possible time to prepare one of the ten pre-series copies, which were already beginning to be released. assemble as DI-6M-25, for field tests with the elimination of all detected problems and the installation of an RI ZIET radio station.

In order to assess the ground attack capabilities of fighters, the USSR aeronautical development plans for 1934 called for the development of the following attack aircraft models:

LSh-1 – Based on the Polikarpov I-16M-22;

LSh-2 – Based on the Kochierigin/Yatsenko DI-6 (Russian: Кочеригин, Яценко ДИ-6Ш);

LSh-4 – Based on the Sukhoi I-4 and Polikarpov I-5 fighters;

LSh-5 – On the basis of the I-9, I-10 and I-11 fighter projects

The Kochierigin/Yatsenko DI-6Sh was also known as TsKB-38 because the prototype was developed at the Central Construction Bureau factory. Ground attack aircraft of 1935 developed on the basis of the DI-6 fighter by VP Yatsenko in the collective led by SA Kochierigin.

As a result of these plans, the TsKB-38 (DI-6Sh) two-seat fast attack aircraft was conceived, obtained from modifications to the DI-6 biplane fighter developed by Kochierigin.

On August 4, 1935, the S-96 request from the Labor and Defense Committee (STO) was received, which established the modification of the DI-6 as an attack aircraft with a maximum speed between 340 and 350 km/h at sea level and 390 -400 km/h at 3000 m, a landing speed between 90 and 95 km/h, radius of action of 400 – 500 km. Armament was to include six 7.62mm machine guns for attack, one machine gun for rear hemisphere defense, plus a bomb capacity of 80kg. According to this document, GUAP, through Factory No.39, had to develop the prototype in a period of 45 days, allowing it to be delivered without armament, in order to assess its installation once the tests were carried out. The GUAP was also requested industrial preparation for production at Factory No. 81 of the Di-6Sh from [1936].

The DI-6Sh was a development of the DI-6 and kept the same structure. Unlike the fighter version, armored protection was added to the pilot’s back and head and the configuration of the armament was modified, which came to consist of two PV-1 synchronized machine guns firing through the propeller, another four PV-1located under the lower wing at an angle of 12º7” towards the central axis of the aircraft and with 3,000 projectiles (4,000 in the overloaded version). There was also a weapons bay located under the pilot’s seat with a capacity for 40 kg of 8-10 kg bombs and the possibility of placing another 4 under the wings for a total of 80 kg. Two VAP-6 containers for chemical weapons could also be located on the underwing mounts.

Defensive armament consisted of a 7.62mm ShKAS machine gun in the gunner’s position with 750 rounds.

With a flight weight of 2,115 kg, the DI-6Sh developed a speed of 305 km/h at sea level and 358 km/h at 3,000 meters. Climb time to 5,000 meters was 17.5 minutes.

Between October 31 and November 19, 1935, the factory and range tests of the first example DI-6ShM-25 developed at the TsKB of Factory No.39, in the department directed by VP Yatsenko, were carried out.

The tests included only 10 flights. In eight of them the machine guns were tested and they worked without problems and in three bombardments with AO-8 aviation bombs were carried out and in two the spraying of chemical weapons from VAP-6 underwing containers was tested. The underwing machine guns worked properly. A range was prepared with wooden targets simulating soldiers and cavalry. Shooting in low flight, 80% of the models were hit, with more than 20% of the impacts concentrated in the groups of callery. The test was considered positive, noting that at flight heights greater than 17 meters, the pilot’s visibility towards the target decreases considerably. The tests of chemical weapons and the launching of bombs were also positive from the point of view of the work of the equipment.VVS, Yákov I. Álksnis, who decided to develop further armament tests of the DI-6Sh model with the participation of experienced pilots brought from operational units.

The tests showed that the model was not ready to act as an attack aircraft, not because of problems with the plane, but due to the inability of its configuration. During an approach flight to the target, the pilot’s attention was focused on controlling the aircraft and the gunner, on the other hand, he could not help at all due to his position, with his back turned. The pilot lacked the possibility of orienting himself using a map to reach the objective. The bomb load, located under the pilot’s cabin, meant an additional task for him and was ineffective because the pilot was unable to take aim as the target was covered by the body of the plane. All these reasons led to the loss of the main characteristic of an attack aircraft: the concentration on the ground objective. On the other hand, the range of the model, the number of bombs and their weight made the model useless as an attack aircraft. The long takeoff and landing run made it difficult to operate from battlefields.

On the other hand, the pilots complained that the quantity and caliber of the bombs did not meet the operational needs of the plane. Controlling the aircraft in low-altitude flight became difficult because the aircraft began to vibrate and it was necessary to exert great force on the joystick.

Despite the difficulties, the DI-6Sh was accepted for series production and 61 examples were produced at Factory No. 1 from the end of 1936.

In the summer of 1938, dive bombing regimes with angles between 40 and 90º were tested on the DI-6Sh. As a result of the tests, the recommendations for this type of action were created, establishing a height at the beginning of the dive of no less than 2,500 meters. The dives showed that the aircraft could react to them favorably and the tail vibrations that characterized the model did not occur during the descent.

The deficiencies of the model as an attack aircraft made the decision to use it for training missions for the first stage of preparing the pilots for bombing and diving tasks. The lack of capacity to load bombs and the low caliber made its use as an attack aircraft in combat conditions impractical. For this reason, most of the DI-6Sh ended up in bombing training units.

Despite the country’s efforts, the attack aircraft of the Red Army arrived at the end of the 30s in a state of crisis. Although 12 attack regiments were registered by this time, the inspection carried out in the attack units in the first half of 1938 showed that the level of operation was really low. The diversity of models and the lack of technical availability characterized the attack structures. Of the 561 aircraft of this type there were 200 Polikarpov R-5 units, 62 Polikarpov R-5Sh units, 174 Polikarpov R-5SSS units, 60 Kocherigin/Yatsenko DI-6Sh units, 31 Tupolev R-6 units and 14 Tupolev SB.

Along with the DI-6Sh, Factory No. 39 delivered in February 1936 two pre-series DI-6M-25 (also sometimes named DI-6I highlighting its use as a fighter) for the development of tests under conditions of Campaign. These tests were led by the NII VVS airfield commander, Major Spirin and included in the brigade were weapons engineer Ssorin and test pilot AI Nikashin. The first tests of the DI-6 were carried out in February with skis undercarriage. The tests of the two prototypes were carried out until April 10, when the snow began to melt and flights were no longer possible. These two with wheels participated in the festivities for May Day. At the end of May, at the NII VVS aerodrome, a third prototype joined the tests.

Field tests ended in June 1936. Mock combat between DI-6 and Polikarpov I-15, I-16 and R-5 reconnaissance aircraft took place. With respect to the R-5, the DI-6 was superior both in vertical and horizontal maneuvers. With respect to the fighters, the advantage of the DI-6 appeared during maneuvers through the vertical.

In June 1936 the first series DI-6 arrived at the NII VVS. Engineer AI Nikashin and test pilot E. Yu. Prieman made 33 flights on it over 28 days. After two years of development, it was not possible to significantly improve its performance. The addition of equipment and improvements based on test data brought about an 81 kg increase in weight. The maximum speed decreased by 16 km/h and the takeoff run had increased by 70%. Tail vibration when entering steep dives could not be fixed. The gunner’s firing angles still did not satisfy the VVS. The main problem was that they were practically the same as those that had been reported since the first tests in the NII VVS. It has been commented that many of the unresolved problems were due to Yatsenko’s difficult nature, which several of his colleagues branded as stubborn and as a person who did not like to give up. However, the DI-6 had already been approved for serial production, so Yákov I. Álksnis was forced to request GUAP to correct all the defects indicated in the aircraft that were already being produced at Factory No.81 as a condition to receive them at the VVS.

In 1937 the series DI-6 began to arrive in units. Meanwhile at the NII VVS work continued to try to improve the airplane. For the month of June, the series DI-6M-25s produced at Factory No.81 began to arrive. These copies had even bigger problems, including some already corrected during development.

In the fall of 1937 test pilot Nikashin began testing a further improvement of the DI-6M-25 built at Factory No. 81. It differed by presenting an “Eklips” (“Эклипс”) electrical system for starting the engine, made up of an accumulator and a DFS-500 (ДФС-500) generator; a radio system SPU-2 (СПУ-2); improved fuel system with welded tanks; oil cooler of new type and new wheels on the landing gear. The fixing of the protective panels in the gunner’s cabin was modified. In emergencies both panels would come loose. The engine hood was also improved and a new 2.8 meter diameter propeller was added. Another important improvement was introduced in the firing angle of the gunner. All this new equipment increased the weight of the device to 2033 kg, which meant an increase of 159 kg with respect to the TsKB-11, and 80 kg in relation to the first series aircraft of Factory No. 81.

In December 1937 the test pilot Nikashin and his assistant Sokolov completed the state tests of the improved version DI-6M-25B (No. 81024), which differed mainly in the new M-25B engine.of 775 hp, the location of the tailplanes in a lower position, the increase in the area of the ailerons by 0.25 sq.m, the addition of an audible signal for landing gear deployment and retraction. Control of the wheel brakes was transferred to the joystick. The wing machine gun feed system was modified from a Factory No. 81 proposal. The tail modifications significantly decreased vibrations and the tendency to lift the tail on takeoff. Brakes on the lever turned out to be more comfortable than on the pedals. Despite the increase in weight coupled with these modifications, the sec benefits were quite close to those of the first prototype. Despite being slightly inferior in manoeuvrability, the DI-6M-25Bit featured the same horizontal speed as the Polikarpov I-15bis.

In January 1938 the latest version of the DI-6 was tested, the DI-6bis (Airplane “21”). This model was powered by an M-62 engine with a variable pitch propeller. When the prototype was finished at Factory No. 81, the engine was not yet ready, so an M-25B with a constant-pitch propeller and 2.8 m diameter was installed. Unlike previous models the DI-6bis featured fixed landing gear, a single cover oved the pilot and gunner cabins, the controversial tank located in the upper center plane was eliminated and the capacity of the wing tanks was increased, the machine guns were located on the wing and the boxes with the ammunition under the bottom plane. The support of the gunner’s weapon, the brake system (which returned to pedal control) was also modified. The lower wing was fitted with flaps.

During the tests, a decrease in the maximum speed at sea level of 16 km/h and at 3000 meters of 29 km/h was verified. Rate of climb and manoeuvrability were practically unchanged. A set of characteristics if considerably improved: improved take-off, the tendency to turn to the left during the take-off roll disappeared. Landing with the flaps became more complex. The angle of fire of the gunner was improved, which featured a new KTP-5 sight. In the conclusions of the tests it was reflected that the “21” Aircraft, even with the M-62 engine, was not in a condition to compete with the new two-seater fighters, therefore its use as a trainer or scouting aircraft was recommended. Factory No. 81 was requested to make changes to the second cockpit to adapt the aircraft to these new roles. The second prototype with these changes was never completed due to lack of supply of the M-62 engine. In total, 222 examples were built.

The first three series examples tested in the NII VVS, together with seven others, were framed from October 1936 in the 56th fighter brigade of the Kiev district.

The operational career of the DI-6 was not very long. In the second half of 1939 it began to be withdrawn from fighter units, being replaced by the Polikarpov I-15bis. In that year the few copies that remained in operation in the units of the Kiev district were assigned to reconnaissance tasks in two squadrons. Most of the other examples in service were used solely as attack aircraft, but with a capacity of only 40 kg, even in this role it could not be considered effective. In the fall of 1939 the 56th Assault Regiment of the 52nd Aviation Brigade from Omsk, in the Siberian District, which maintained 63 DI-6Sh aircraft (of which 8 were out of service) began to operate the Tupolev SB bomber.

Of the 173 DI-6 planes that were in service on January 1, 1940, it was planned to maintain 39 planes in two squadrons, deliver 99 to training centers and withdraw 35. The copies used in the training center were generally used as study material. No evidence of its use in flight has been found. Claims that DI-6 fighters participated in the Battle of Jaljim Gol or the Finnish War are considered unfounded.

Despite the myriad of problems described along these lines, it’s not fair to characterize the DI-6 as a bad plane. During all the time it was operated, there was never a catastrophe and due to the number of problems reported and small breaks, it did not stand out as a leader in its time either.

A replica of the DI-6 is displayed at the Museum of the Great Patriotic War in Moscow.

TsKB-11

Initial designation of the prototype.

DI-6M-25

Main production version as a fighter.

Engine: 1 x 700 hp Shvietsov М-25

Upper wingspan: 9.94 m

Lower wingspan: 7.43 m

Wing area: 25.16 m²

Length: 6.87m

Height: 3.20m

Empty weight: 1360 kg

Loaded weight: 1,955 kg

Normal takeoff weight: 2033 m

Wing loading: 78 kg/m²

Maximum speed at sea level: 324 km/h

Maximum speed at altitude: 372 km/h

Cruising speed: 313 km/h

ROC: 611 m/min

Time to 5000 m: 10 minutes

Practical range: 550 km

Practical ceiling: 7700 m

Armament: Three 7.62mm ShKAS machine guns / 750 rounds each.

Bomb load: 40 kg

Accommodation: 2

DI-6M-25B

Improved version of 1937, lowered tailplanes, increased wing area.

Engine: 775 hp M-25B

DI-6Sh (TsKB-11Sh, TsKB-38)

Attack version with four PV-1 machine guns located under the wings.

Engine: 1 x 700 hp Schvietsov М-25

Upper wingspan: 9.94 m

Lower wingspan: 7.43 m

Wing área: 25.16 m²

Length: 6.87m

Height: 3.20m

Empty weight: 1434 kg

Loaded weight: 2155 kg

Normal take-off weight: 2033 m

Wing loading : 78 kg/m²

Maximum speed at altitude: 358 km/h

Cruising speed: 312 km/h

ROC: 611 m/min

Time to 5000 m: 10 minutes

Practical range: 500 km

Practical ceiling: 7200 m

Accommodation: 2 crew members (pilot and gunner)

Armament: 7 x PV-1 machine guns

Bombload: 80 kg

DI-6bis (Aircraft “21”)

Fixed landing gear. Designed for M-62 engine, tested with the M-25B. Just a prototype.

DI-6MMSh

A prototype with an M-300 engine. Its acronym stands for Small Attacker Modification (малая модификация штурмовика). It was not produced.