General Electric ran performance tests of its 32,000 lb.-thrust F 110-GE-132 engine for Block 60 F-16s at its Peebles, Ohio, facility.The engine, the first complete, purpose-built F 110-132 began about 30 hr. of runs at Peebles on an outdoor test stand. Preceding those trials were 30 hr. of tests conducted in indoor facilities at GE’s Evendale, Ohio, plant. Those assessments were finished in midNovember 2000.

Thrust is the biggest difference between the F 110-132 and the production version of the F 110, the F 110-129. The newer engine is capable of generating about 3,000 lb more thrust under sea-level static conditions. To generate that power, the -132 is fitted with a 5% more efficient fan that features integrally bladed disk construction. The new powerplant also has a filament wound graphite-epoxy fan duct designed to handle the loads associated with thrust vectoring, should that technology ever be added to the engine.

The F 110-132 is equipped with a radial augmentor, similar to the unit found in the F/A-18E/Fs F414 engine. It improves operability at higher thrust levels and helps eliminate augmentor screech-high-frequency, standing sound waves that can damage engine components.

Also offered as an option on the F l10-132 is an ejector nozzle that directs a thin film of cool air from the engine bay around the nozzle’s flaps and seals. Cooling is great enough to reduce the temperatures of those components by 400-800 deg. F, depending on operating conditions.

Taken together, the F 110-132 improvements can be used to generate additional thrust, or to increase engine life if thrust is limited to 29,000 lb. This means inspections now carried out on F 110s at 4,300 cycles would be delayed to 6,000 cycles.

F 110-132s operated under the increased durability option would carry the official USAF designation of F 110-GE-132As. Despite the designation, the service has not taken any steps toward procurement.

Applications:

F-14B/D Super Tomcat

F-15S/F-15K/F-15SG/F-15SA Strike Eagle

F-16 Fighting Falcon

General Dynamics F-16XL

Mitsubishi F-2

Specifications:

F110

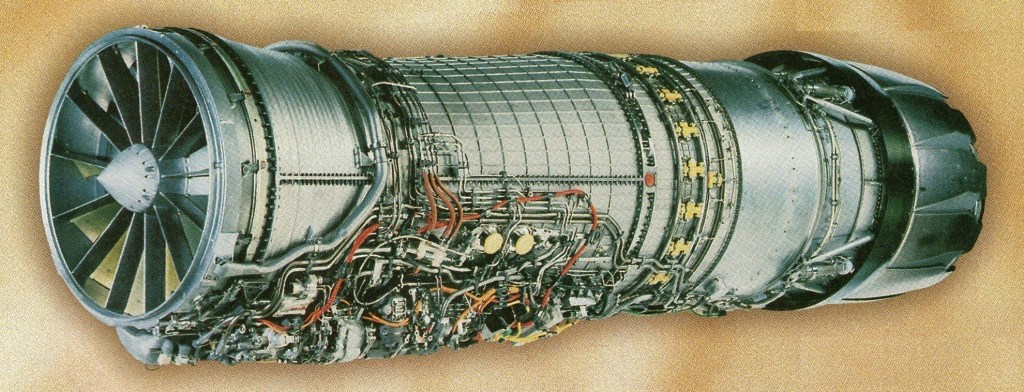

Type: Afterburning turbofan

Length: 182.3 – 232.3 in (463 – 590 cm)

Diameter: 46.5 in (118 cm)

Dry weight: 3,920 – 4,400 lb (1,778 – 1,996 kg)

Compressor: 2 spool: 3 fan and 9 high pressure compressor stages

Combustors: annular

Turbine: 2 low-pressure and 1 high-pressure stages

Maximum thrust: 27,000 – 28,000 lbf (120 – 125 kN)

Overall pressure ratio: 29.9:1 – 30.4:1

Turbine inlet temperature: 2750F (1510C)

Thrust-to-weight ratio: 6.36:1