At the beginning of 1933 it became necessary to find a replacement for the aging Túpolev TB-3 bomber, which formed the basis of the long-range bomber aviation of the RKKA VVS. At the same time it became known that a group of professors and assistants from the Zhukovski Military Aeronautical Academy had been working on the conception of a new giant 12-engine bomber known as “Gigant”. By 1934 the need for an aircraft of these proportions had waned, so the financing of the project was cancelled. It was proposed to this group to develop a capital reconstruction project for TB-3.

Viktor Fedorovich Bolkhovitinov became the head of the VVIA design group at the VVA Žukovskij (VVS academy Žukovskij ) tasked with the design of a replacement for the Tupolev TB-3 heavy bomber. It was decided to study in depth the limitations of TB-3 and propose solutions to improve them. To this end, consultation work was started directly with the builders of Factory No.22 in Fili , where the Túpolev bomber was produced.

The new aircraft was designed as a Long Range Bomber or BDD (Russian: бомбардировщик дальнего действия – БДД). The technical tasks approved by the VVS for the new bomber in December 1934 included a speed of 320 km / h, a landing speed of 90-95 km / h, a flight ceiling of 6000 – 7000 m and a transport capacity of 1000 kg of bombs at a distance of 4000 km (with a total load capacity of 5000 kg). For its projection, a Joint Projection Bureau (OPB) was created, made up of technologists and builders from the factory and designers from the Zhukovski Academy.

The proposals put forward by the Academy were supported by RKKA chief of armament M. N. Tukhachevsky.

The Academy’s group of specialists conceived that, maintaining the tooling of Factory No.22, it was entirely possible to create an aircraft capable of meeting the specifications of the VVS and even in some cases exceeding them.

Soon Bolkhovitinov’s brigade was transferred to Factory No.22 in Fili, where the KB-22 was organized. Already participated in the projection of the new model. M. Kuritskies, IF Florov, BE Chertok, MM Shishmariov, among others.

The factory name for the new model was “A”. The Commission analysis of the model met on 14 January 1935, leaving some constructive recommendations for changes, the composition of the weaponry and equipment. By this time it was clear that even when the dimensions and composition were maintained constructively, it was a new aircraft. Despite this, it is remarkable that many official documents of the time refer to the new model as “the last modification of the TB-3 ” or “the TB-3 of 1935 “.

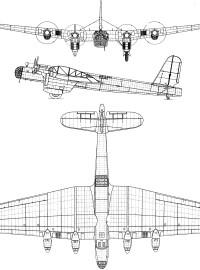

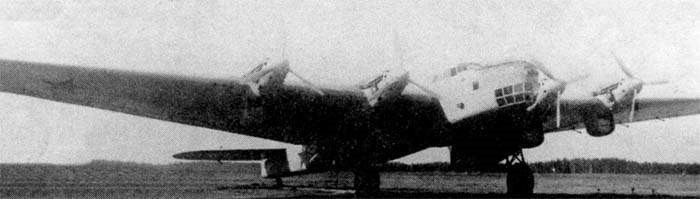

The resulting Bolkhovitinov DB-a (Russian: Болховитинов ДБ-А. Its acronym comes from the term Long Distance Bomber – Academy, Russian: Дальний Бомбардировщик – Академия) was advanced for its day with stressed skin aluminium alloy construction throughout with clean lines, neatly cowled engines and trousered main undercarriage legs, with fully retracting main-wheels and tail-wheel. The split flaps, undercarriage, nose turret and bomb-bay doors were all operated by a pneumatic system re-charged by engine driven compressors.

Upgraded bombs with 6 x 2 m hatches, mechanized and armoured Tur-8 turret and closed cockpits for the crew (with the exception of the tail gunner).

The new fuselage with a monocoque structure made it possible to significantly increase the interior volume of the aircraft. In the lower part of the center was located the bomb bay with a capacity for 3000 kg of bombs in the following configurations:

8 bombs of 250 kg;

6 bombs of 500 kg;

2 bombs of 1000 kg;

or 24 bombs of 100 kg.

The ability to install VAP-500 and VAP-1000 external supports, as well as a rotary launching system for RRAB pumps, was envisaged.

In the nose there was a Tur-8 turret with a ShKAS machine gun, which rotated with the help of a pressurized air system and in the central area of the fuselage a Tur-Aldis turret, designed in the TsAGI, with a ShVAK 20mm cannon. To defend the belly area, a ShKAS machine gun was installed firing through a hatch. In the tail area, the installation of a TUR-8 turret with another ShKAS machine gun was planned. The cannon had 250 rounds, while the total ammunition load for the machine guns reached 3,000 units.

The wing had a structure with three spars and a TsAGI – 620 profile. It was made up of the centrewing and two wing consoles. Nine fuel tanks accommodated 14,600 liters and two 460-liter oil tanks were located in the wing between the engines. In the intrados the underwing supports were located with a total capacity of 2000 kg of pumps. Both the flaps and the ailerons had a metallic structure and textile covering. The use of these flaps, capable of operating at 60º, allowed the landing speed to be reduced to 80 km / h.

The operation of the flaps, the retraction and extension of the wheels, the turning of the bow turret and the opening and closing of the hold gates were carried out by means of a pneumatic system.

The DB-A incorporated an APR-3 radio-rangefinder. The project also included the addition of an AVP-10 autopilot system. Both crew members communicated with the help of an intercom system. For night landings, the placement of headlights under the wings was foreseen.

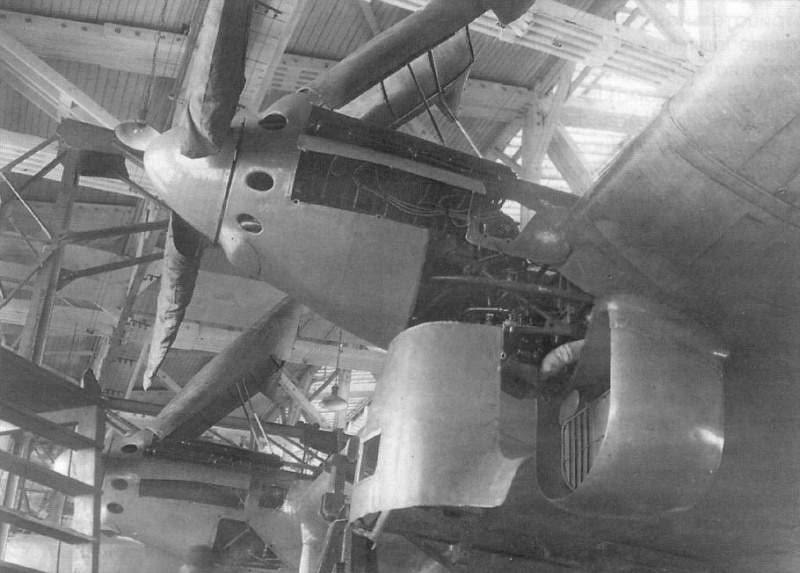

The power plant consisted of four M-34RN engines. The project was calculated for the turboed version M-34FRN, but this model became available later.

The landing gear was designed as a conventional type with a tail wheel. The main units featured 2000x450mm wheels that partially retracted into large ‘pant’ type fairings. To allow the exploitation of the aircraft in winter operations, the use of special skis was envisaged, but these were never built, so for the factory tests the skis of a TB-3 were used. The main landers used telescopic, hydro-pneumatic shock absorbers.

The DB-A crew of nine were two pilots, a navigator, two engineers, a radio operator – gunner and three other gunners, but in different configurations it varied between 6 and 9 people.

In November 1934 the construction of the first copy of the DB-A (Dalni Bombardirovchik – Akademia or Long-range Bombardment of the Academy) was completed. Instead of the M-34FRN engines required by the project, four M-34RNs with a lower power were installed in the new prototype.

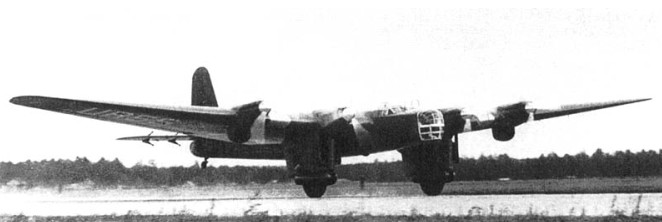

Flight trials began on 2 May 1935 at Khodinka piloted by factory pilots N.G. Kastanyev and Ya.N. Moseyev, Later, due to Moiseyev’s illness, he was replaced by AK Tumansky, brother of the aircraft engine manufacturer Sergei Konstantinovich Tumansky . The crew also included engineers Godovikov, Florov, Konkin and Osipienko.The first flight of the new “22A” factory index bomber lasted barely half an hour, but it demonstrated the value of the technical solutions applied to the “Annushka” (Anita) as the workers of Factory No.22 where it was developed called it.

Initially, the DB-A engines had wooden propellers with two blades and a diameter of 4.35 m, similar to those used in the TB-3, but this brought about a noticeable decrease in performance in relation to those calculated, therefore It was decided to replace them with one of three 4.1 meter blades, similar to those used in the Túpolev ANT-25.

Factory tests were completed by April 1934 and NII testing was carried out in May and June 1935. In them it was shown that the DB-A out-performed not only the TB-3, but even the Farman-222 with a similar mission. Despite presenting an empty weight 15.4 tonnes higher than that of the TB-3, the DB-A showed an increase in speed of 40 – 50 km / h. This increase in performance was mainly due to the aerodynamic improvement of the model. With retraction of the landing gear, 18-20 km / h were gained at sea level and 25-28 km / h at 2000 meters. The performance demonstrated included, sustained flight at an altitude of 2,500m (8,202 ft) with two engines shut down, and 4,500 km range.

The aircraft assessment report only included poor visibility from the cockpit as a defect. However subsequent investigations have shown that the report was not objective. There is evidence of contradictions between Kastanayev and Tumanski, as the former eliminated the defects from the reports in order to get the plane to be chosen for the long-haul flight to the United States proposed by the polar pilot SA Levanevski.

The aircraft was shown to Levanevski and government approval was soon received to prepare the first factory specimen No.22-A1 for flight, assigning it the USSR-N-209 polar aviation index.

In 1936 the DB-A was shown in the parade commemorating the first of May, causing a sensation among national and foreign guests.

A decision was made to fly non-stop from Moscow to the USA and the DB-A was modified to fly, at an overload weight of 34,700 kg (76,500 lb), carry enough fuel to fly 8,440 km (5,244 miles). While the state tests were being carried out, the first DB-A was modified and prepared for the record flight on the Moscow – North Pole – Fairbanks route. The plane was lightened. All weapons were removed; the glazing of the forward cabin in which the navigator and radio operator were located was modified; an astrological dome was installed over the pilot’s seat, the position of the tail gunner was removed. The weight saved went to a new fuel tank and commercial cargo.

During the preparation of the flight, a test flight was carried out on the Shelkovo – Baku – Shelkovo route and a test takeoff with a weight of 32,300 kg.

The flight across the North Pole on the red painted DB-A prototype USSR-N-209 began on August 12, 1937 from Moscow Shchyelkovo airport on an attempt to fly to Fairbanks, Alaska. The crew consisted of SA Levanevski as pilot and captain, NG Kastanayev as second pilot, VI Lievchenko as navigator, mechanics GT Pobratimov and NN Godovikov and radio operator N. Ya. Galkovski.

Although the weather conditions on the route were extremely difficult, it was decided to continue the flight. On August 13 at 1:40 p.m. Moscow time, the crossing over the North Pole was reported. At 14:32 the last radio communication was received informing that an engine had stopped. Then the link was lost. The plane was never found, despite intensive searches carried out for almost a year. In more recent times, attempts have been made to continue searching using more advanced search techniques, without obtaining any results.

In order to verify the performance obtained during the prototype factory tests, it was decided to deliver the second prototype, known as DB-2A, to the NII VVS to carry out the state tests, which began on March 14, 1936. This model was equipped with a more powerful version of the M-34RN engine rated at 1000 hp and a new radiator.

The main pilot for the tests was MA Nyuxtikov and the principal engineer Losiukov. The flight results set in these tests were:

Maximum speed at sea level: 280 km / h

Maximum speed at 3000 meters: 323.5 km / h

Maximum speed 4200 meters: 330 km / h

Landing speed: 80 – 85 km / h

Practical ceiling with weight of 21,600 kg: 7,220 m

Take-off run: 300 – 350 m

The evaluation report of the state tests, signed by the head of the VVS Ya. I. Alksnis on June 1, 1936 concluded: “Compared to the TB-3 4M-34RN aircraft, the DB-2A prototype presents the following improvements: 1 – Considerable increase in horizontal speed. With the use of M-34FRN engines for which it was calculated, the speed should be increased until reaching 360 – 370 km / h. 2 – The large capacity of the fuel and oil tanks, at the overloads for which the aircraft was calculated, guarantee a great range. ” But there were a series of defects whose enumeration reached 38 points. Among them:

1 – Unsatisfactory stability and handling;

2 – Low effectiveness of the ailerons and great pressure on the lever during its operation;

3 – Low effectiveness of the rudder and great pressure on the lever during its operation;

4 – In flight regime between atmospheric turbulence, the effectiveness of the tail decreases significantly with rolling. A prolonged flight in these conditions is made impossible by the pilot’s fatigue.

5 – Appearance of strong vibrations in the tail unit in some flight regimes.

Despite not being included in the official report, Tumansky had highlighted other defects, including the impossibility of completing the oil capacity in flight, the inability to use the last 60 kg of oil in the tanks, due to the location of the system nozzles. Piloting the plane required great physical strength and there was no oxygen system for the crew.

Several improvements were made to the aircraft that included modifications to the aileron and rudder control systems. The appearance of strong vibrations in the tail section forced a flight weight limit of 21,800 kg to be established. Upon learning of this, Boljovitinov himself together with the test pilot MA Nyuxtikov conducted a test flight, managing to find a weak point in the aircraft’s structure, which was soon reinforced. With this it was possible to raise the takeoff weight to more than 30,000 kg.

The DB-A was flight tested with only three engines. In this case the maximum speed decreased to 292 km / h, the ceiling with 21,500 kg of weight reached 5100 meters. It is noteworthy that in the tests an engine was never really disconnected, but the power was reduced to the maximum. With two engines working, the plane was unable to exceed 2,500 meters in height.

In the flight tests there were several mishaps that luckily did not end in disasters:

On March 11, at an altitude of 2000 m, due to a power failure during the climb, the four engines stopped and only the quick action of the pilots who managed to stabilize the horizontal flight, guaranteeing the necessary flow of fuel to the engines. was able to avoid an accident.

On May 21, 1936, during landing 67 and due to a manufacturing defect, the left leg of the landing gear broke.

In June 1936, installation tests were carried out on the DB-2A of the M-34FRN engines with take-off power of 1220 – 1240 hp and new metal propellers. It was decided to develop a new test suite on the NII VVS. These tests were developed by the third rank military engineer MA Lipkin and had MA Nyuxtikov as the main pilot.

The M-34FRN engines (with factory numbers № 436, 437, 4311, 4314) were experimental and did not pass the test because they were considered unreliable. Compared to the M-34RN they had a power increase of only 50 – 70 hp. It was impossible to install them on the plane until its completion by Factory No.24.

In the report of the test results with the new powerplant signed by the head of the VVS Ya. I. Alksnis on November 2, 1936 it is found that:

“… The installation of the M-34FRN engines in the DB-A aircraft, due to its low working height and lack of completion, negatively influenced the flight data of the aircraft, excluding the speed performance (maximum speed grew at 10 km / h)”.

In the conclusions of the state tests Alksnis also wrote:

“Taking into account that the DB-A significantly surpasses the TB-3-4M-34RN in performance and that the defects indicated in the state tests can be solved during the construction of the field series, consider it essential to begin preparation for production series of these aircraft based on the results of field tests”.

In 1936 itself, the process of preparation for serial production began. At that time a contradiction was created between Bolkhovitinov and the director of Factory No.22, Tarasievich. The factory had been instructed to restore production of the TB-3 and a large production plan for SB bombers. On the other hand, Túpolev had begun to propagandize the series production of his TB-7. For this reason, Tarasievich submitted to Glavaviaprom (of which Tupolev was deputy chief engineer) the request to develop the production of DB-A in Kazan, at Factory No.124. This request soon became a decision sanctioned by the Commissariat for Heavy Industry.

This decision directly affected the group. Bolkhovitinov could not refuse to move, as this meant refusing to produce the bomber. KB members received the documents for a lengthy service commission. Several specialists were unable to transfer and others simply did not want to do so, for example Kuritskies and Shishmariov, who taught at the Academy, decided not to leave the VVA.

Only two complete copies had been built at Factory No.22: the DB-A prototype and the second DB-2A. A third uncompleted specimen was sent to Factory No.124 in Kazan for completion. As a basis for serial production it would be necessary to build 4 or 5 aircraft, which were to be produced at Factory No.22.

Although initially it was planned to have the first copy ready for December 1936, the construction of the plane was delayed. At the beginning of 1937 all the forces of Factory No.22 focused on the first copy in order to be able to deliver it for testing on February 8.

In April 1937, joint tests began with the contractor of the first specimen intended for field tests, produced at Factory No.22. This aircraft was a modified DB-2A. Among the main differences was the fully retractable landing gear. Initially 1350×300 mm wheels were selected but it was shown that they did not support the maximum flying weight of the aircraft, so other 1600×500 mm wheels were chosen. The cockpits for the pilots, navigator and mechanics had been totally modified and raised to improve visibility. This caused the deck to protrude from the fuselage, ending in a fall in which it was thought to locate a ShKAS machine gun.

On the nose was the two machine gun system used in the SB. In the central region there was a turret with a ShVAK cannon that rotated with the help of an electric motor. The initial turret, now equipped with a PMP-2 collimator, was kept in the tail.

This new specimen received the name DBA-37 or simply DB. The test brigade was made up of the test pilot MA Nyuxtikov, the second pilot and engineer Antojin, the armament engineer Stvietkov and the chief engineer of Factory No.124 Volkov.

As a result of the second stage of testing, the surface and trim area of the rudder was increased. Later, the construction of the cellar hatch opening system was changed, the engine exhaust system was modified, the trimmers and the aileron and rudder compensation system were modified, among other minor changes. For crew communication, a new intercom system SPU-1 was adopted and RSTB-1 and RSB radios were added. The crew grew to 11 people. The changes continued until the end of 1937.

The first modernized DB-A copy was completed only for the month of May. Factory tests with M-34RNV engines took place between May 11, 1937 and March 22, 1938. The test brigade in this case consisted of the test pilot MA Nyuxtikov, the second pilot and engineer Antojin, the chief engineer of Factory No.22 Frolov and the engineer of Factory No.124 Garanovich.

Compared to the first copy, the handling worsened. With respect to the first prototype, the take-off weight had increased by 2000 kg and the maximum speed to 3000 meters was increased by only 8 km / h, so the modifications had been insignificant.

The long duration of the tests was due to the fact that, after the disappearance of Levianevski, the works in the DB-A were stopped and only continued in early 1938.

The first stage of state testing of the modernized DB-A took place between October 21 and December 20, 1937. After several modifications to the aircraft, the tests were continued at the NII VVS between April 14 and June 24, 1938. The final result of the tests was generally positive, for which the series production of 16 copies was authorized.

Between August 26 and September 28, tests were carried out with the M-34FRN engines with turbochargers and VISH-3B propellers of 3.9 m diameter. The tests were carried out in conjunction with the NII VVS. A total of 13 flights were carried out, of which 6 were carried out at altitudes of more than 9000 meters. They aspired to reach 11,000 meters, but the poor work of the compressors did not allow this result to be achieved. With this new power plant, the empty weight of the aircraft grew by 910 kg, reaching 17,722 kg. The takeoff weight was close to 24 tons.

Only 12 copies had been built by the end of 1939, when production was halted in favour of the Túpolev TB-7. The built specimens were destined for the 5th Long Range Bomber Aviation Corps of the RKKA VVS in the Far East. In 1940 there were 6 DB-A bombers in service there. At the beginning of the war these aircraft were not transferred to the European region of the USSR, serving basically as transports until the end of their useful life.

In 1940 the problems presented with the production of the TB-7 brought to the table for discussions the issue of restoring the production of the DB-A, but from there it did not happen.

Among the possible development variants to eliminate the problems of the use of a lower performance powertrain than the projected one, the use of Charomsky AN-1 diesel engines was valued.

Records:

The 10 November of 1935 pilots MA Nyuxtikov and MA Lipkin set a new world record for the lifting 10 tons of weight to 7,032 meters high.

On 20 November 1935 these pilots set a new record holder for the lifting 13 tons to 4,535 meters.

The 14 May 1937 pilots GF Baydukov. NG Kashtanayev and LL Kerber flew in a DB-A on the Moscow – Melitopol – Moscow route covering 2002.6 km in 7 hours 2 minutes and 11 seconds with a payload of 5 tons. Two world records were set on this flight:

Speed of 280 km / h in distance of 1000 km with 5 tons of load.

Speed of 246 km / h in distance of 2000 km with 5 tons of load.

Variants:

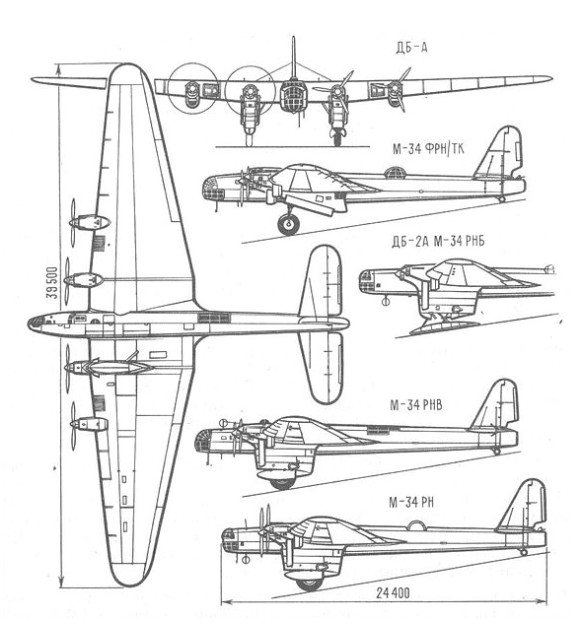

DB-A – The initial prototype aircraft, with M-34RN engines, lost on a non stop flight Moscow to Fairbanks, Alaska.

DB-2A – The second prototype with many detail improvements and M-34RNV engines.

DBA – Production aircraft ordered in 1937. Sixteen aircraft ordered, but only twelve completed, with M-34FRN engines plus turbo-chargers, rearwards retracting main undercarriage, gunners cockpits in the rear of the inner engine nacelles, and other modificatoions.

TK-1 TK ( – heavy cruiser) – Projected escort bomber with 11 crew, 3xShVAK + 3,000 rounds, 5xShKAS + 11,000 rounds and underwing rockets.

Specifications:

DBA

Engines: 4 × M-34FRN + turbo-chargers, 970 hp

Wingspan: 39.5 m (129 ft 7 in)

Wing area: 230 sq.m (2,476 sq.ft)

Length: 24.4 m (80 ft 0-5/8 in)

Stabilizer wingspan: 12.5 m

Height: 8.50 m

Wheelbase: 7,690 m

Empty weight: 16,150 kg (35,605 lb)

Gross weight: 22,000 kg (48,500 lb)

Power load: 5.7kg / hp

Wing loading: 95 kg / m²

Maximum speed: 316 km/h (196.4 mph)

Maximum speed at 4000 m: 330 km / h

Cruising speed: 260 km / h

Range: 4500 km (2,796 miles)

Service ceiling: 7,730 m (25,360 ft)

ROC: 135 m / min

Climb to 1000 m: 5 min

Climb to 7000 m: 56 min

Crew: 6 – 9

Armament:

2 x ShKAS 7.62mm machine-guns in each of the inner nacelle gun positions.

1 x ShKAS 7.62mm machine-guns in nose and tail positions.

1 x ShVAK 20mm cannon in the dorsal turret.

5,000 kg of bombs in internal bomb-bay.