The idea for creating the Belyayev DB-LK (Russian Беляев ДБ-ЛК) came from Belyayev as a result of the successful results obtained with the BP-2 and BP-3 gliders. In 1938 Belyayev proposed a long-range bomber, converting an airliner project of designer Leonid l. Selyakov, The power design was done by PN Obrubov and DA Zatvan. The fundamental objective of the new design was to outperform the Ilyushin DB-3 bomber, which by that time had entered service with the VVS.

The requirements set for the new bomber included a maximum speed of 550 km / h at 7000 meters and a range of 4000 km with a bomb load of 1000 kg. At the beginning of 1938, the project was handed over to the aeronautical industry management for review, where its continuation was authorized.

The next step was the construction of a life-size wooden model. This time this step was justified with greater force. The originality of the construction required significant development, which had to be designed and tested on the model. In the spring of 1938, after lengthy discussions and a number of changes, the model was finally approved by the special commission of the VVS and the decision was made to authorize the construction.

The commissioner of defense of the USSR, Marshal K. Ye, was included in the evaluation commission. Voroshilov, who liked the design and decided to sponsor its construction. The group of engineers made up of Selyakov, Obrubov, Zatvan, Plejanov, Yerujimovich, Meyerson, Kartashkin, among others, got to the task, which began under the motto “Voroshilov Task” and was soon called DB-LK. of D alni B ombardirovshik – L etayuche K Rylo bomber or long range – flying wing.

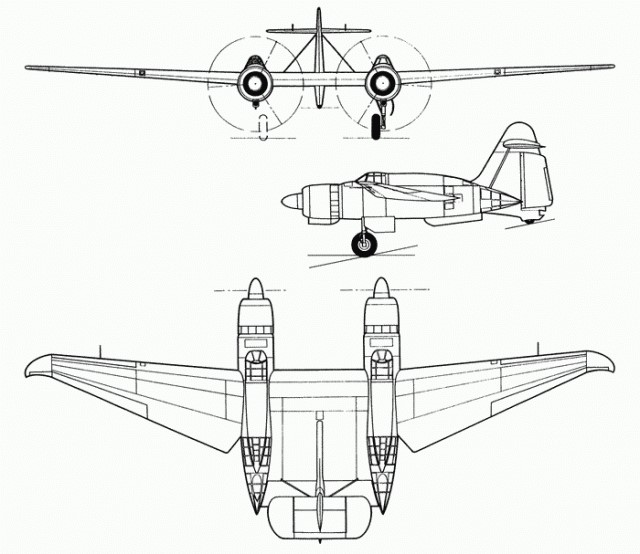

Belyayev himself defined the scheme of his airplane as ” flying wing “, although in practice it does not fully correspond to this category

In the projection and preparation period, the aircraft had received the designation “Request 350” or “350”. For its construction in Factory No.156 a Construction Bureau was organized , which designated KB-4, would be under the direction of Belyayev and Selyakov. As substitutes, Obrubov and Zatvan were appointed.

Organizational changes in the industry in 1936 and the number of arrests of specialists and workers in 1937 had considerably weakened the factory and by 1938 there was a lack of new jobs. For this reason, the management of Factory No.156 welcomed the assignment of a new task.

The aircraft was constructed entirely metal, with duralumin coating on the fuselage and the leading edge of the wings and fabric on the control surfaces and the rest of the wing plane.

The new aircraft was conceived with a double fuselage structure formed by the lengthening of the driving nacelles, in which two 950 hp Tumansky M-87B radial engines were installed. Each moto-gondola ended in a cone with a widely glazed surface in which the defensive gunners of the rear hemisphere were located.

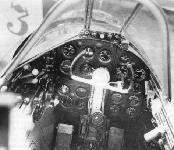

The fuselage had a semi-monocoque structure with three main frames and four spars. In the fuselage on the left the pilot and the shooter were located and in the right the navigator and the shooter-radio operator. The cockpit cover was positioned slightly to the left, to improve visibility on approach. The cockpits were located in a high position, just behind the engines.

The DB-LK was defined in the documents as a “nearly tailless type flying wing”. During the development of the project, great attention was paid to the “Belyayev” wing with inverted deflection at an angle of 5 ° 42 at the leading edge. The wing consoles had a double stringer structure and were originally conceived with a NASA 23012 profile. Each console tapered its chord towards the ends and ended in a backward curvature, where small ailerons were located. The aerodynamically compensated Frize main spoilers took up more than half the span of the console. Opposite these ailerons were self-operating slats, designed to ensure safety at critical flight angles. Large area flaps capable of 45º were located throughout the rest of the span. The ailerons could be directed downwards when extending the flaps, to increase the lift of the aircraft.

The centroplane, with a structure of 5 stringers, was designed using an S-profile of the GLASS D-1 type with a tapered front. Adjustable balance flap surfaces were installed along the entire length of the trailing edge, which were lowered during take-off and raised at an angle on landing. These surfaces were conceived with the aim of reducing the pressure on the steering bodies. In front of these flaps, on the intrados of the centerplane, there were aerodynamic brakes that worked in a synchronized way with the wing flaps.

This configuration allowed a fairly high wing loading, reaching 160 kg / m² and with it the designers wanted to achieve the breakdown of the flow in the centre plane rather than in the wing consoles for critical angle of attack manoeuvres.

The wind tunnel tests showed that these claims would not be met in practice, so the wingtips were soon modified. Finally, the TsAGI MV-6bis profile was defined for the centroplane and the Gettingen-387 profile in the wing consoles.

The centerplane ended in a large keel topped by the 2 m² horizontal stabilizer and the 0.86 m² elevator. At the bottom of this keel was located the fixed tail wheel, conveniently faired. Originally the stabilizer featured small vertical surfaces at the ends and a weight balance system, but these features were later removed.

The conventional-type landing gear featured 900 × 300 mm single-wheel main landing gear, which retracts rearwardly into the corresponding fuselage. The tail wheel was fixed and was conveniently faired by a structure that was part of the keel.

To the first frame of each fuselage, the powerplate made of welded steel tubes was fixed. Initially the use of two Tumansky M-88 engines of 1100 hp was conceived, but after the accident that caused the death of Valeri Pavlovich Chkalov, the use of this engine was for a certain time prohibited, so the designers had to be content with it. less powerful M-87B from the same manufacturer, capable of developing 950 hp at 4700 meters. The fuel system consisted of two protected tanks in each of the wing consoles, another two located at the base of the wings and seven more (5 large and two small) located in the center plane. The total capacity of the 13 tanks reached 3444 liters.

In the last frame, the glass movable section of the gunner’s cabin was fixed with a machine gun that could rotate 360º. A little further back was the glass cone with another machine gun located horizontally. In this way the defense of the rear hemisphere could be covered with four machine guns. Each of the shooters had to serve both machine guns.

Apart from this defensive armament, the DB-LK had two ShKAS machine guns located in the central region of the center plane. If necessary, these machine guns could be directed at an angle of +/- 10 °, by means of a remote control system. The bomber carried 4500 rounds for the 6 ShKAS machine guns.

Under normal conditions the bomber could carry 1000 kg of bombs in different configurations, from four 250 kg FAB-250s to 58 small caliber bombs. In overloaded configuration the DB-LK could carry two FAB-1000 or FAB-500 bombs on external supports under the center plane.

The construction of the prototype was started at Factory No.156 in Moscow from the publication on July 29, 1939 of Resolution No.248 of the Defense Committee. Although the aircraft had already received the designation DB-LK, the manufacturing designation “350” remained in use.

The first DB-LK was completed by September 1, 1939. The aircraft was soon handed over to the NII VVS in Shelkovo for the development of factory tests, which were assigned to engineer TT Samarin and test pilot MA Nyuxtikov. In November, the first runs began on the airfield.

It is noteworthy that at that time Soviet test pilots were sceptical of tailless aircraft designs and the arrival of the DB-LK at the NII VVS did not bring great interest. The testers disparagingly nicknamed the plane “kuritsa” (hen), a bird with wings unable to take flight.

At that time the expansion of the aerodrome was carried out. New areas were levelled, but in some places there were irregularities that were filled with wood. The first runs on the DB-LK were carried out by the head of the NII VVS, General Filin. In one of these tests, when reaching 240 km / h one of the undercarriage hit a stump hidden on the edge of the runway by snow. The plane fell onto the wing, damaging the propeller and tail wheel. The problem was soon resolved, but this incident contributed to the doubts of the pilots.

The aircraft was returned to the factory for repair and in the early 1940s, after reinforcing the undercarriage and making another series of minor modifications, the DB-LK was returned to the NII VVS.

The test pilot Nyuxtikov performed not only runs, but small jumps. During one of the take-off attempts, the flaps of the centroplane erroneously moved to the landing position and raised its nose. Those present at the tests panicked thinking the worst, but the aircraft soon lowered its nose on its own and settled gently on the ground after automatically activating the wing leading edge slats.

The prolongation of the tests without achieving the first flight began to make the Commissariat for the Aeronautical Industry (NKAP) impatient. Belyayev went to the substitute of commissioner AS Yakovlev requesting that the pilot be replaced. A week later a similar request came to the head of the NII VVS Filin from the head of the 11th address the NKAP Leontiev. However, no volunteer candidate appeared to fly the “chicken”.

A commission was created to evaluate how the tests should be carried out, but without waiting for it, the DB-LK with the pilot Nyuxtikov at the controls took off. This happened on March 8, 1940. Engineer TT Samarin was in the cockpit on the right. Another of the many tests was carried out and the plane had made two small “jumps”. During the execution of a third the DB-LK suddenly took flight. Fearing the behavior of the plane in the turn at low altitude, Nyuxtikov decided to take altitude and after stabilizing the plane, he made a smooth landing.

Before the snow melted, factory tests had been completed and a number of major defects corrected. The air intakes of the engines were lengthened to prevent them from filling up with snow during races on the track.

In April 1940 the DB-LK had its skis removed and wheels fitted. In this configuration it was delivered for the development of state tests.

The most difficult test of the DB-LK took place on May 1, 1945. In the traditional aerial demonstration over Red Square, which accompanied the festivities, the new aeronautical models were shown and the impression they made on the personalities gathered there (especially Stalin) could guarantee the future of the model.

The day before the parade the DB-LK was prepared with great care. The preparation was entrusted to Belyayev’s replacement, Obrubov, who at the last moment decided to modify the extension made to the air intakes, considering that in the absence of snow, they were meaningless and made the power plant ugly.

The following morning a squad of bombers prepared for takeoff for Red Square, kicking up huge clouds of dust. This dust accumulated in the air intakes of the DB-LK’s engines, which lost the force necessary for take-off. In what they managed to disassemble and wash the filters it took some time. By the time the DB-LK passed over the rostrum, Stalin had already withdrawn.

Delivered for state testing on the NII VVS in April 1940, the DB-LK would make its maiden flight on the 25th. Testing lasted for two months, until June 25th. The test program comprised 73 flights with a total duration of 45 hours in the air. During this period the plane was flown by several pilots apart from Nyuxtikov, among whom Filin, Jolopsiev, Kabanov, Stefanovski and Dudkin stood out. During the tests, two aerial combat drills were carried out with a Messerschmitt Bf-109E, bought from Germany.

The pilots highlighted as positive the aircraft’s ability to fly with a single engine, even maintaining the climb in these conditions with a speed of 1.15 m / s. Single-engine turns were not difficult for either side. With the two engines the plane made turns without difficulty. The glide was smooth at speeds of 240 km / h and the landing was quite good, but the landing speed of 155 km / h was considered high.

As a result of tests, a large number of changes were made to the DB-LK. The rudder surface was increased from 4.27 m² to 4.8 m². The trim for the elevator, steering and ailerons has been decreased. The entire rear section of the centroplane was converted into an auxiliary elevator with an area of 0.58 m². The surface of the empennage was enlarged to 7 m². To guarantee the centering of the aircraft, weights of 280 kg were added to the hoods of each engine nacelle.

The tests carried out with the M-87B engines yielded a speed of 488 km / h, well below that requested, although higher than that of the most modern Soviet serial bomber at the time, the Ilyushin DB-3. The M-87 engines were inferior in power to the M-88 with which it was designed.

The take-off and landing speeds were considered to be too high. The tail took off with difficulty at speeds close to 100 km / h and about 180 km / h had to be achieved to achieve takeoff. The test pilot had noticed a tendency during takeoff to turn to the right.

The range during the tests could not be defined due to the regulations placed on the flying weight of the aircraft. The commission allowed DB-LK flights as long as a takeoff weight limit was maintained, citing trim problems, weak landers, high landing speeds and a long run.

Another major complaint from the pilots was related to the cockpit configuration, which was considered narrow and uncomfortable, especially the navigator’s cockpit. Visibility to the front and down was considered unsatisfactory.

The gunner’s cabin was considered uncomfortable and did not allow service to the two machine guns. On the other hand, these cabins were filled with the exhaust gases from the engines, which made it almost impossible to stay in them without a gas mask.

Armament tests determined that the forward hemisphere was barely protected due to the poor firing angles of the machine guns and poor frontal visibility from the cockpits of the pilot and navigator. On the other hand, in the gunner positions, if the upper machine gun was used to defend frontal attacks, there was no way to keep the observation behind, which left the plane totally unprotected. The upper machine gun was annoying during the operation of the rear and when it was operated, the frontal hemisphere was totally neglected.

Under these conditions the aircraft could not complete the test cycle. The commission’s report highlighted shortcomings and recommended returning the aircraft to its builders in order to improve manoeuvrability, armament performance, and take-off and landing characteristics and to have it ready for a second round of testing, which was scheduled for October 15 as 1940.

In August 1940 Belyayev showed the list of modifications necessary to meet all the requirements set out by the military. The originally simple modifications had been greatly complicated. It was about:

Replace the M-87 engines with the 1500 hp M-81 engines, modifying the entire drivetrain and the front area of the fuselage.

Replace the wing landing flaps with louvered flaps and insert a new auxiliary wing slat.

Achieve the synchronized work of the flaps with the stabilizers.

Modify the landing gear to a tricycle configuration.

Modify the structures of the fire points.

At that time, the military made another request that radically modified the design. It was about converting the plane into a dive bomber with a central cockpit over the center plane. The Belyayev collective took the task seriously and the development of the modifications was carried out. As a result, the configuration of the new model, which received the internal factory designation “360” or “New DB-LK”, changed greatly from the base model.

The new cockpit in the center plane was presented as an aerodynamic nacelle. Four different variants were tested in the TsAGI’s T-2 wind tunnel. There were also tests of the take-off and landing systems. As a result, it was decided to install slats along the entire span of the leading edge of the centroplane. The gunners, one of whom would act as navigator, were located in the rear section of each of the fuselages with individual glass covers to improve 360º visibility.

Work was carried out on the external system for fixing the pumps and the addition of aerodynamic brakes, mandatory to regulate speed during bites, as well as an automatic exit system for them.

Aerodynamic tests of the new model were carried out until the beginning of 1941. In the last variants analyzed, it was planned to install 2000 hp M-71 engines, which should allow reaching a speed of 590 km / h at 6000 meters of altitude. The flight weight with military bomb load increased to 10,600 kg and the calculated ceiling was 10,500 meters with a normal range of 1,500 km and 4,000 meters in autoloader.

A conceptual project with AM-37 linear motors was developed, which received the designation “380” in the KB-4 numbering.

On 20 September 1940 Victor Belyayev received the title of doctor of technical sciences. The possibility of transferring the KB-4 to Bykovo or Smolensk was analysed . Factory No.156 had been tasked with producing models “100” and “103” developed by specialists confined under the control of the NKVD, who worked in the factory itself. Under these conditions work on the new DB-LK model stopped.

At the end of 1940 the prototype of the DB-LK remained unattended at the NII VVS airfield. In August of that year the director of Factory No.156, AV Lyapidevski (one of the first Soviets to receive the title of Hero of the Soviet Union for the rescue of the crew of the steam “Chelyuskin”) proposed to deliver the specimen as an exponent static to the Bureau of New Technique of the TsAGI or the Moscow Aviation Institute. In October 1941, when German troops approached Moscow, the decision was made to move the plane to the deep rear, but it was not possible to find pilots capable of undertaking the task, so it was destroyed.

The fate of the DB-LK was determined by the novelty of its design. Despite not meeting the specifications that were established, it is necessary to emphasize that the DB-LK was 30 km / h faster than the fastest competitor in its category. In relation to the ceiling of flight and range, it surpassed the Túpolev SB and Ilyushin DB-3 bombers, which made up the “elite” of Soviet bombing aviation at the time.

Practice showed that the DB-LK scheme brought both advantages and shortcomings, but the former outweighed the latter. The flying wing scheme is more economical in terms of consumption and has a better weight gain ratio than the conventional scheme, but this would be demonstrated only many years later.

DB-LK

Engines: 2 x Tumansky M-87B 950 hp

Wingspan: 21.60 m

Wing area: 56.87 m²

Length: 9.78 m

Height: 3.65 m

Empty weight: 6004 kg

Normal takeoff weight: 9061 Kg

Maximum overloaded weight: 10672 kg

Wing loading: 203 kg / m²

Speed at sea level: 395 km / h

Maximum speed at 5100 m: 488 km / h

Cruising speed: 446 km / h

Landing speed: 150 – 155 km / h

Ascent speed: 370 m / min

Ascent time at 5000 m: 13.6 min

Practical ceiling: 8,500 m

Normal range with 1320 kg of fuel and 1000 kg of bombs: 1270 km

Maximum range with 2,500 kg of fuel and 1,000 kg of bombs: 2,900 km

Take-off run: 600 – 620 m

Landing roll: 550 – 600 m

Armament: 6 machine guns of 7.62 mm and 1000 kg of bombs

Accommodation: 4